Longitudinal axis flow nested differential type corn threshing device

A corn threshing and differential speed technology, which is applied in threshing equipment, agriculture, application, etc., can solve the problems of straw blockage, difficult removal, and aggravated blockage, so as to reduce entanglement and blockage, reduce damage and loss, and reduce The effect of moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

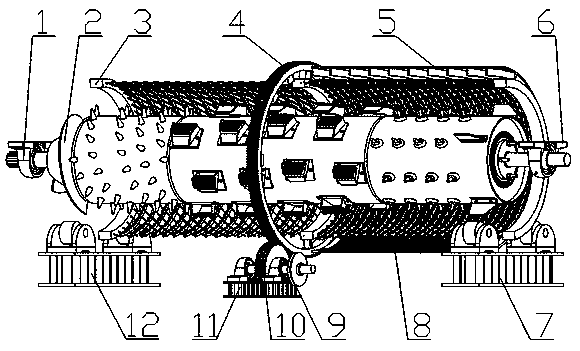

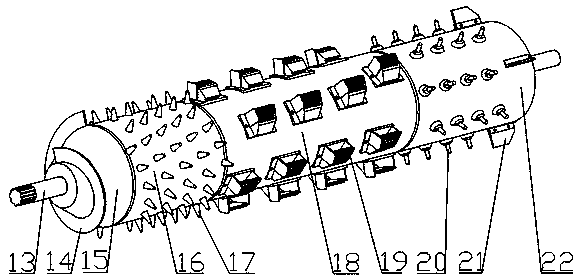

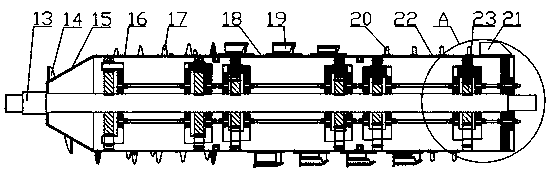

[0018] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a front bearing seat 1, a threshing drum 2, a cylindrical concave plate screen 3, a concave plate screen gear ring 4, an upper shroud 5, a rear bearing seat 6, a rear support 7, and a lower cleaning screen. 8. The pulley 9, the concave plate screen driving gear 10, the middle support 11 and the front support 12, the front bearing seat 1 is fixed at the front of the threshing drum 2, the rear bearing seat 6 is fixed at the rear of the threshing drum 2, the cylinder The concave plate screen 3 is sleeved on the radial outer part of the threshing drum 2, the concave plate screen gear ring 4 is sleeved in the radial outer middle section of the cylindrical concave plate screen 3, and the concave plate screen driving gear 10 is engaged with the lower part of the concave plate screen gear ring 4 , the pulley 9 is fixed on the outer end of the driving gear 10 of the concave plate screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com