Unhulled rice threshing device

A technology of threshing device and paddy, which is applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of time-consuming, large power consumption, and increased machine use cost, and achieves short time consumption, reduced power consumption, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

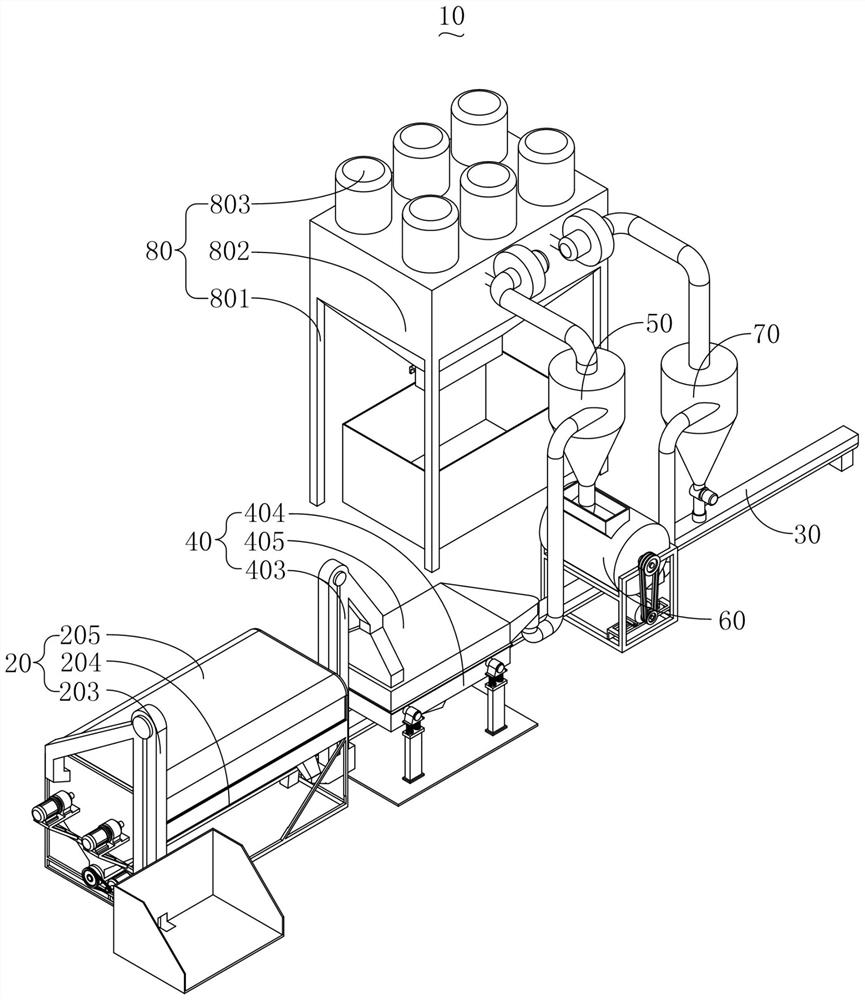

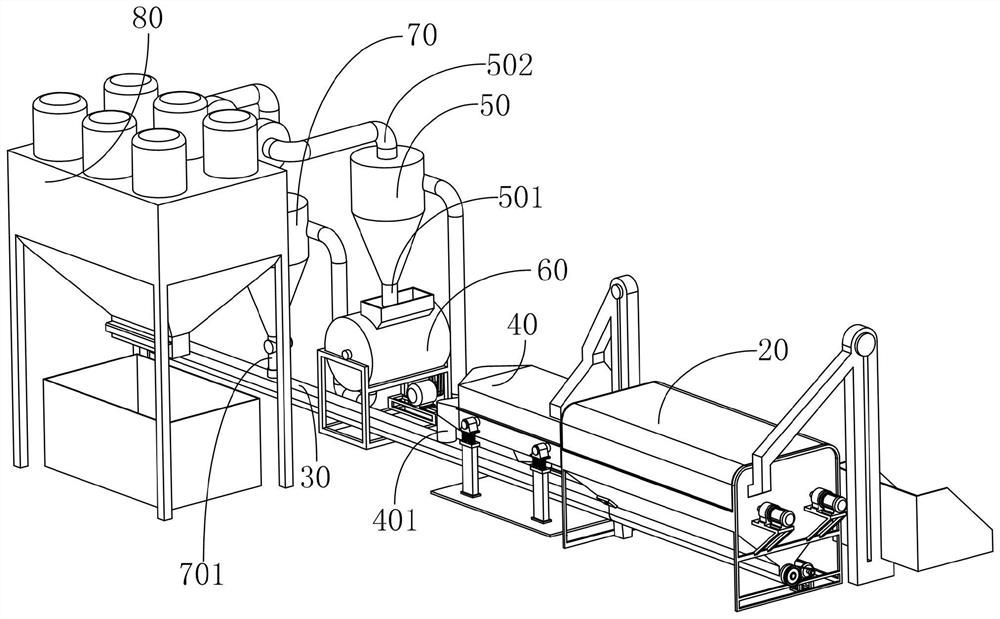

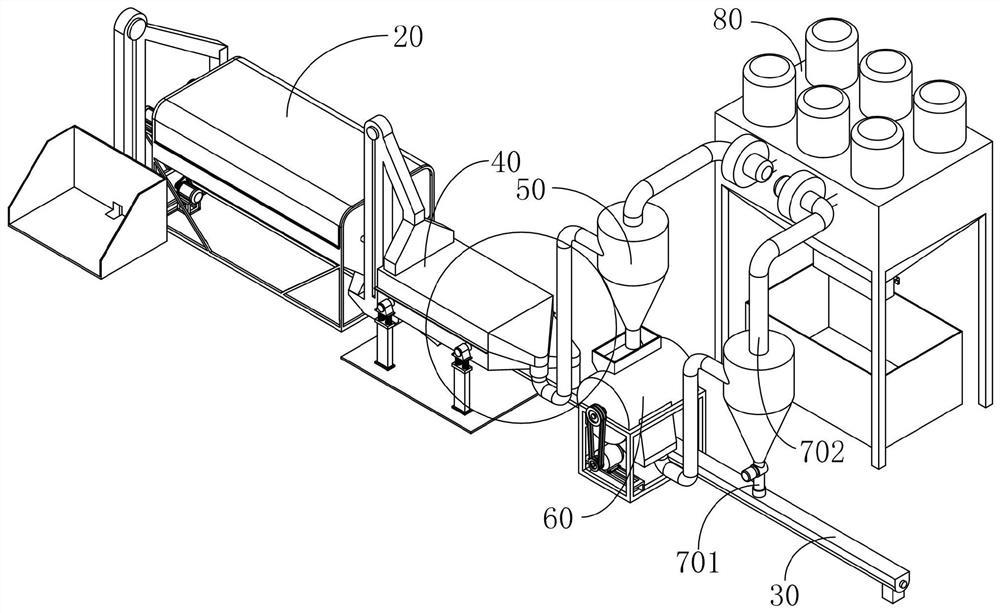

[0015] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

[0016] Please see Figure 1 to Figure 4 , a rice threshing device 10 comprising a cylinder sieve device 20, a rice conveying device 30, a vibrating screen device 40, a first cyclone separation device 50, a rice thresher 60, a second cyclone separation device 70, a straw recovery device 80, a cylinder The sieve device 20 is provided with the first rice discharge port 201, the first miscellaneous material discharge port 202, the first rice discharge port 201 communicates with the feed port of the rice conveying device 30, the first fore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com