Novel corn husking and threshing device

A threshing device, corn technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems that hinder the rapid development of corn harvesters, reduce the working efficiency of corn harvesters, and high threshing damage rate, so as to reduce the breakage rate and Uncleaning rate, threshing effect, and effect of improving work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

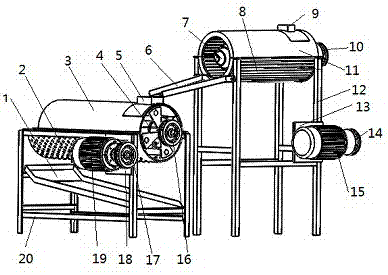

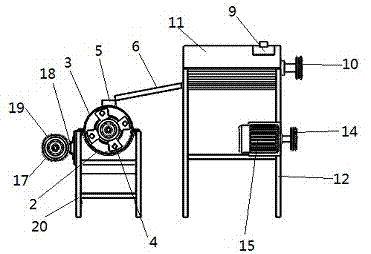

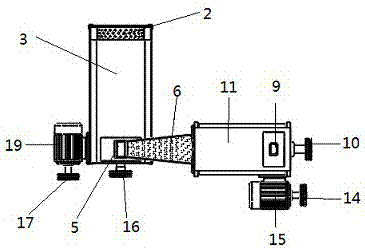

[0016] Refer to the instructions attached figure 1 Attached Image 6 The new corn peeling and threshing device of the present invention will be described in detail below.

[0017] The technical scheme of the present invention is: a new type of corn peeling and threshing device, including a grain recovery slide plate 1, a threshing concave plate 2, a threshing machine cover 3, a threshing drum 4, a first feed hopper 5, a connecting screen 6, a peeling drum 7, a peeling Concave plate 8, second feeding hopper 9, driven pulley I 10, peeling machine cover 11, first frame 12, motor I support 13, driving pulley I 14, motor I 15, driven pulley II 16, driving belt Wheel II 17, motor II support 18, motor II 19, second frame 20, characterized in that the peeling concave plate 8 is connected to the first frame 12 by welding, and the peeling machine cover 11 is connected with The peeling concave plate 8 is connected; the threshing concave plate 2 is connected to the second frame 20 by weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com