Agricultural machinery for threshing various crops

A technology for crops and agricultural machinery is applied to various crop threshing agricultural machinery. It can solve problems such as increasing production cost and difficulty, and increasing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

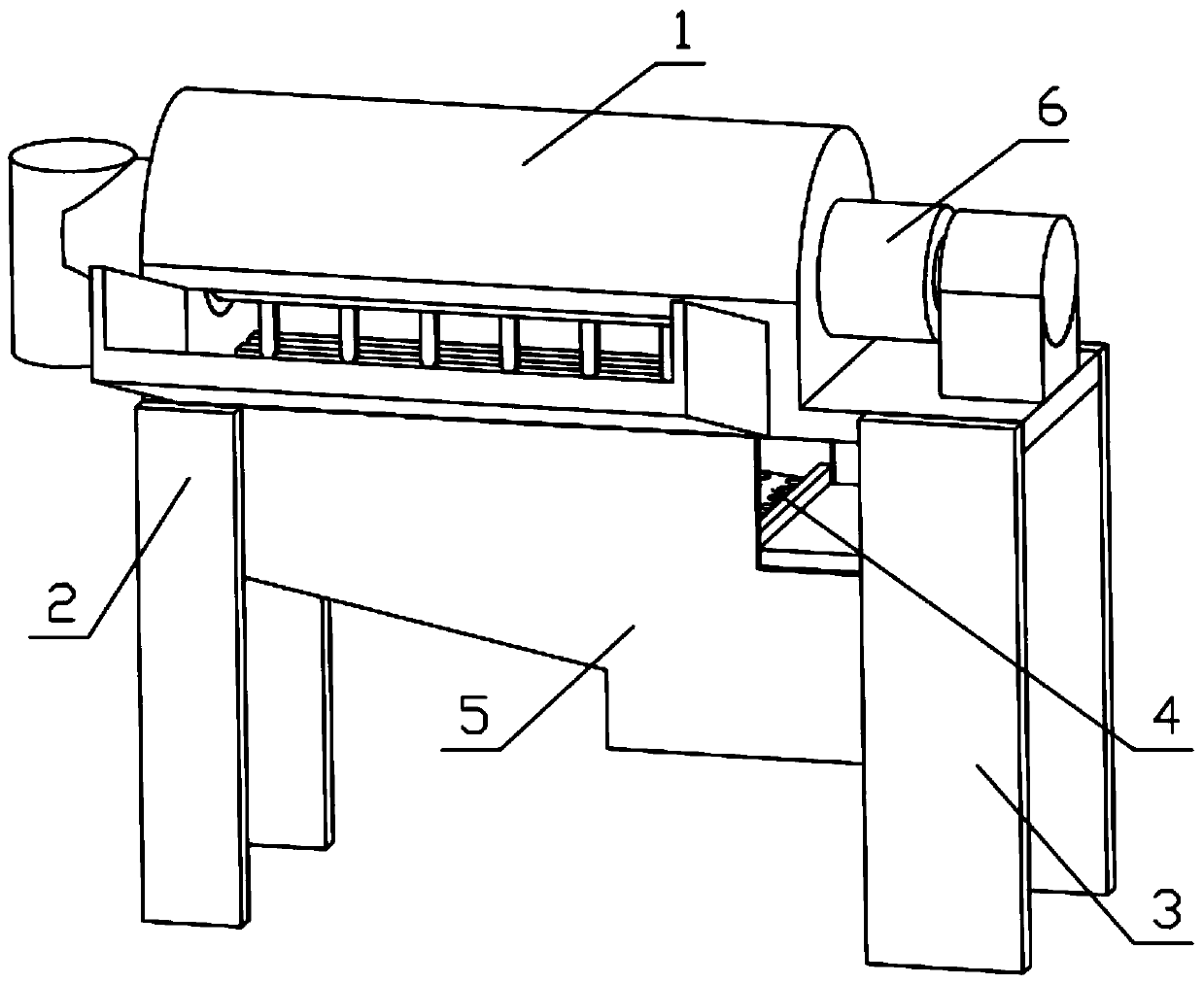

[0033] Combine below Figure 1-13 Description of this embodiment, a variety of agricultural machinery for threshing crops, including a feed seal shell 1, a front support leg 2, a rear support leg 3, a grain filter plate 4 and a bottom seal shell 5, the feed seal shell 1 and The bottom sealing shell 5 is fixedly connected, the bottom sealing shell 5 is fixedly connected with the front supporting leg 2, the feeding sealing shell 1 is fixedly connected with the rear supporting leg 3, and the grain filter plate 4 is rotatably installed in the concave hole provided on the bottom sealing shell 5. On the tank, the threshing mechanism 6 is installed on the feeding sealing shell 1.

specific Embodiment approach 2

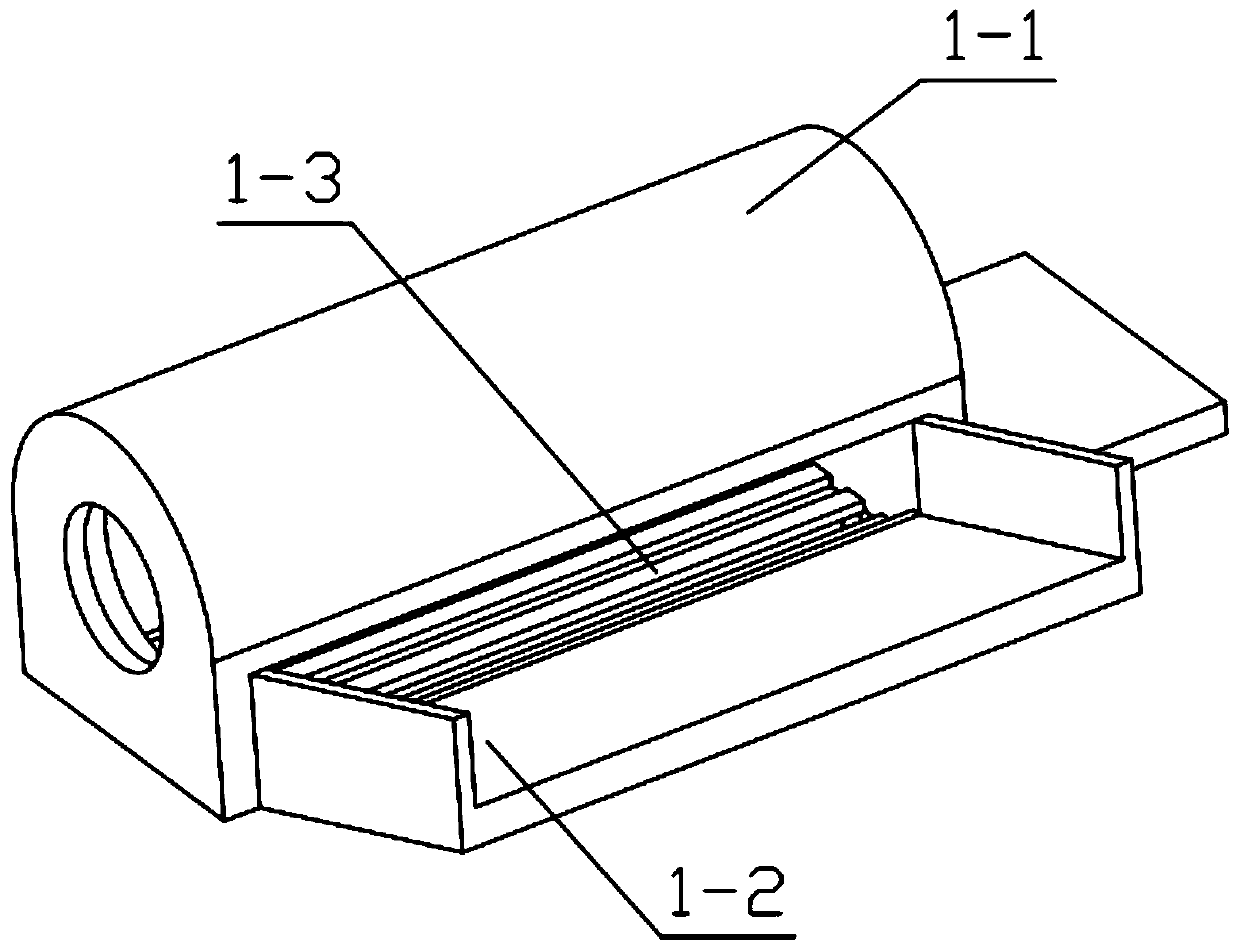

[0035] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain Embodiment 1, the described feed sealing shell 1 includes main sealing cover 1-1, feed pallet 1-2, preliminary screening grate 1-3, feed pallet The plate 1-2 is fixedly installed on the main sealing cover 1-1, the preliminary screening grid 1-3 is fixedly installed on the main sealing cover 1-1, and the preliminary screening grid 1-3 plays the role of a preliminary block to prevent the The crops undergoing threshing operations fall below.

specific Embodiment approach 3

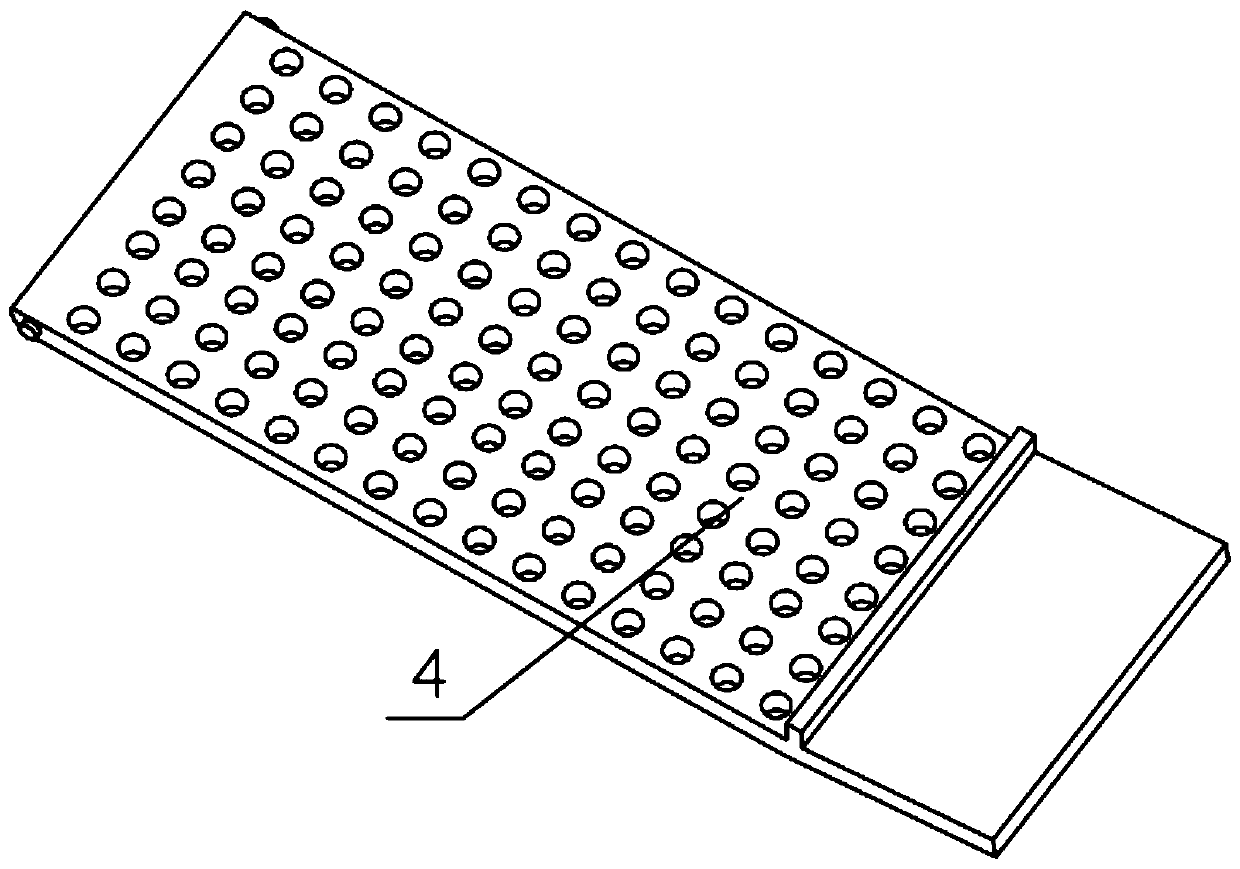

[0037] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the first embodiment, the bottom sealing shell 5 includes the sealing shell main body 5-1, fan grille 5-2, ash discharge grille 5-3, fan assembly 5- 4. The displacement simple adjustment assembly 5-5, the ash discharge grid 5-3 is fixedly installed on the main body 5-1 of the sealing shell, the fan grid 5-2 is fixedly installed on the main body 5-1 of the sealing shell, and the fan assembly 5- 4 Installed on the main body 5-1 of the sealed case, the simple displacement adjustment assembly 5-5 is installed on the main body 5-1 of the sealed case; the fan assembly 5-4 includes a fan motor 5-4-1, a cam 5-4-2, Fan 5-4-3, cam 5-4-2 are fixedly installed on the output end of fan motor 5-4-1, cam 5-4-2 is fixedly connected with fan 5-4-3, fan motor 5-4-1 Fixedly installed on the main body 5-1 of the sealed shell, the cam 5-4-2 is in contact with the grain filter plate 4; the displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com