Cereal threshing device

An equipment and grain technology, applied in the field of grain threshing equipment, can solve the problems of no bagging, danger, low threshing efficiency, etc., and achieve the effects of improving efficiency, saving labor, and efficient threshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

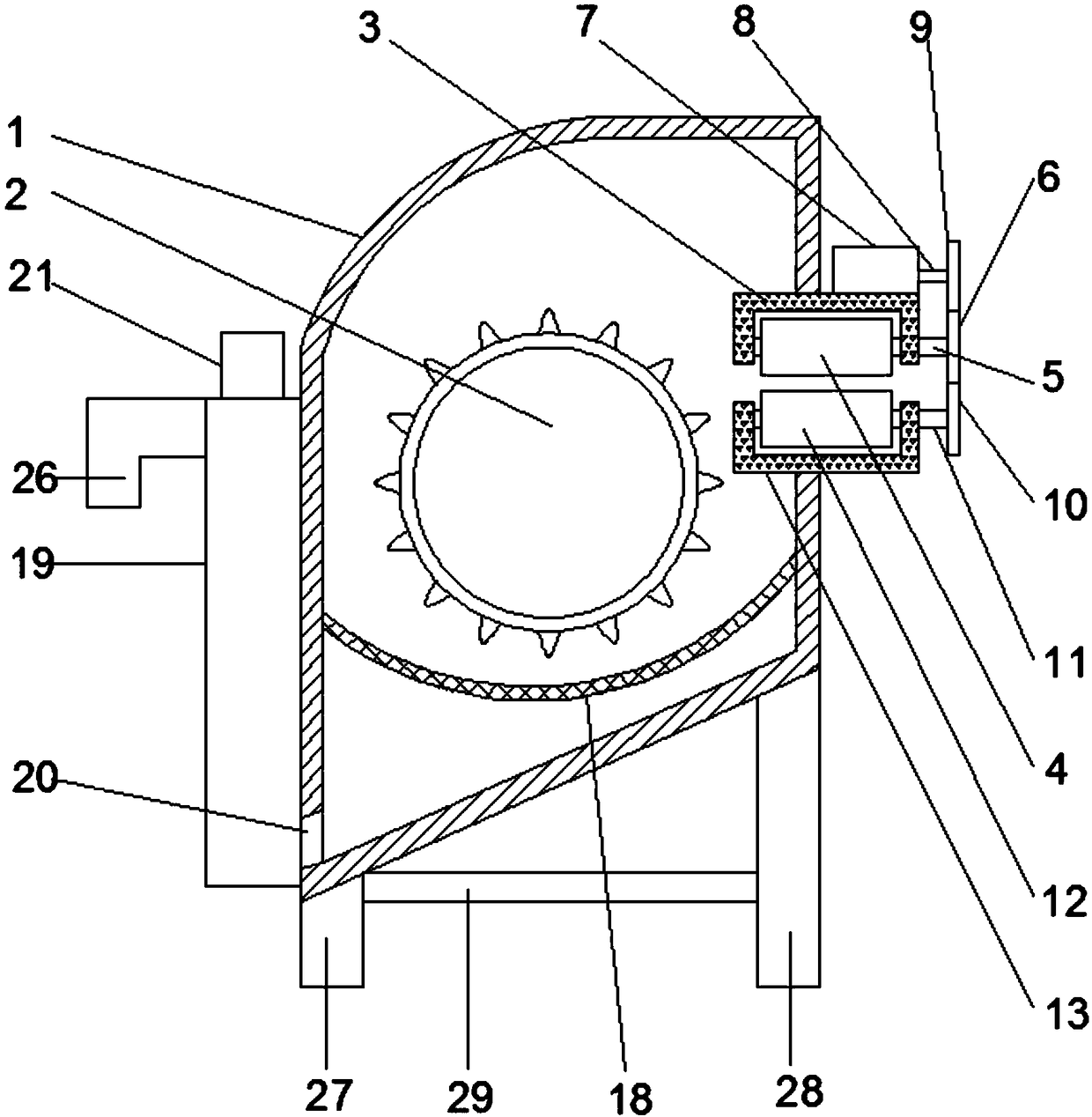

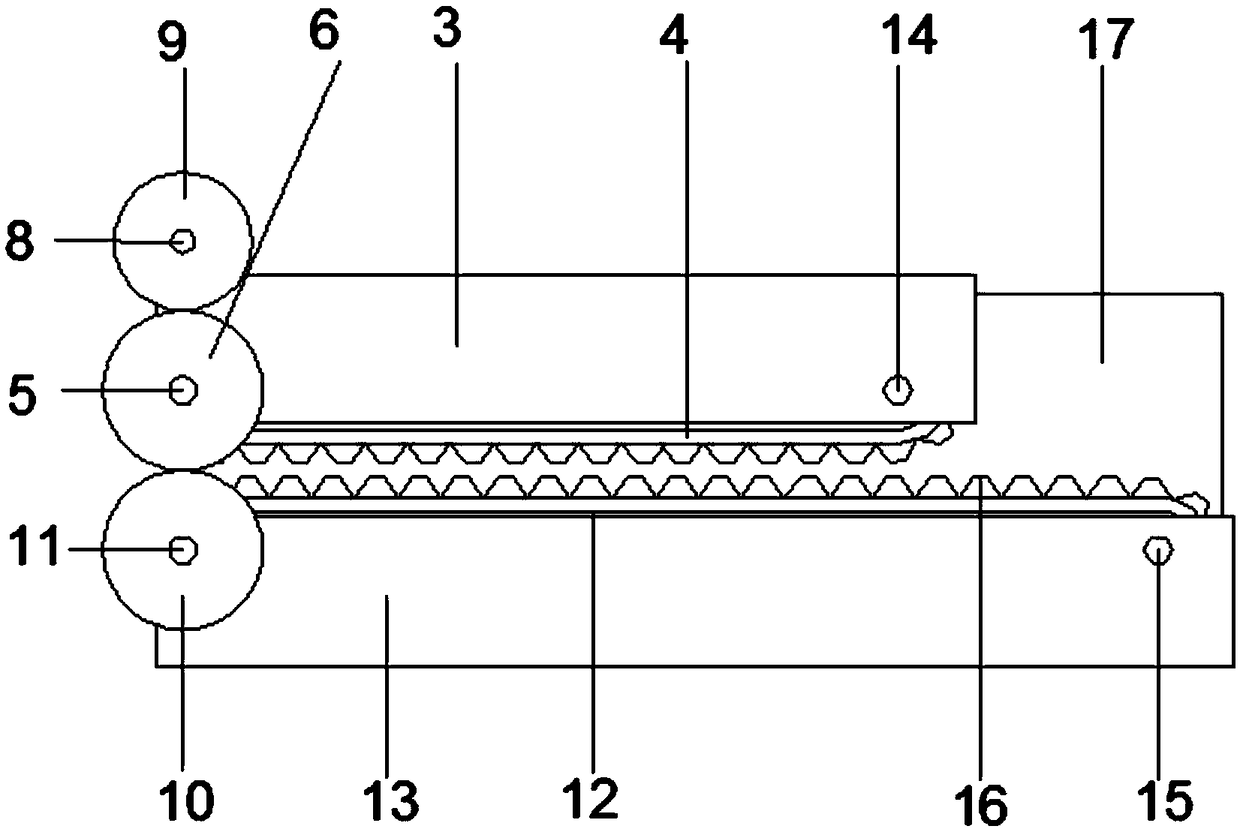

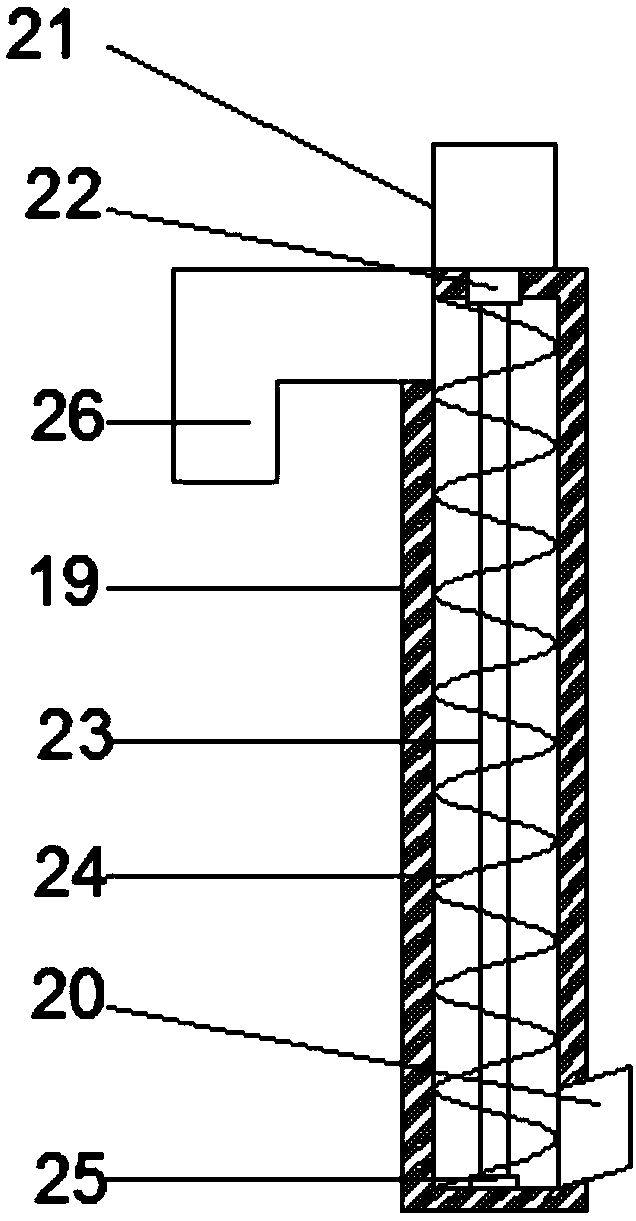

[0019] Such as Figure 1-Figure 3 As shown, the grain threshing equipment proposed by the present invention includes a threshing chamber 1, a threshing drum assembly 2, a first conveyor belt assembly 4, a conveying barrel 19, and a bagging port 26. The threshing drum assembly 2 is provided in the middle of the threshing chamber 1, and the threshing The middle of the right side wall of the chamber 1 is provided with a fixed conveying device on the right side of the threshing drum assembly 2. The fixed conveying device includes a first protective shell 3, a first conveyor belt assembly 4, a first rotating shaft 5, a first gear 6, a first motor 7, The second rotating shaft 8, the second gear 9, the third gear 10, the third rotating shaft 11, the second conveyor belt assembly 12, the second protective shell 13, the first protective shell 3 is provided with the first conveyor belt assembly 4, and the first conveyor belt The front end of the assembly 4 is rotatably connected to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com