Oilseed rape combine harvester

A technology for combine harvesters and rapeseeds, which is applied to the chassis of harvesters, agricultural machinery, agricultural machinery and machinery, etc. It can solve the problems of easy explosion in mature collisions, large threshing and separation load, and reduced operating efficiency, and reduce the quality of the header. , the effect of improving harvesting ability and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

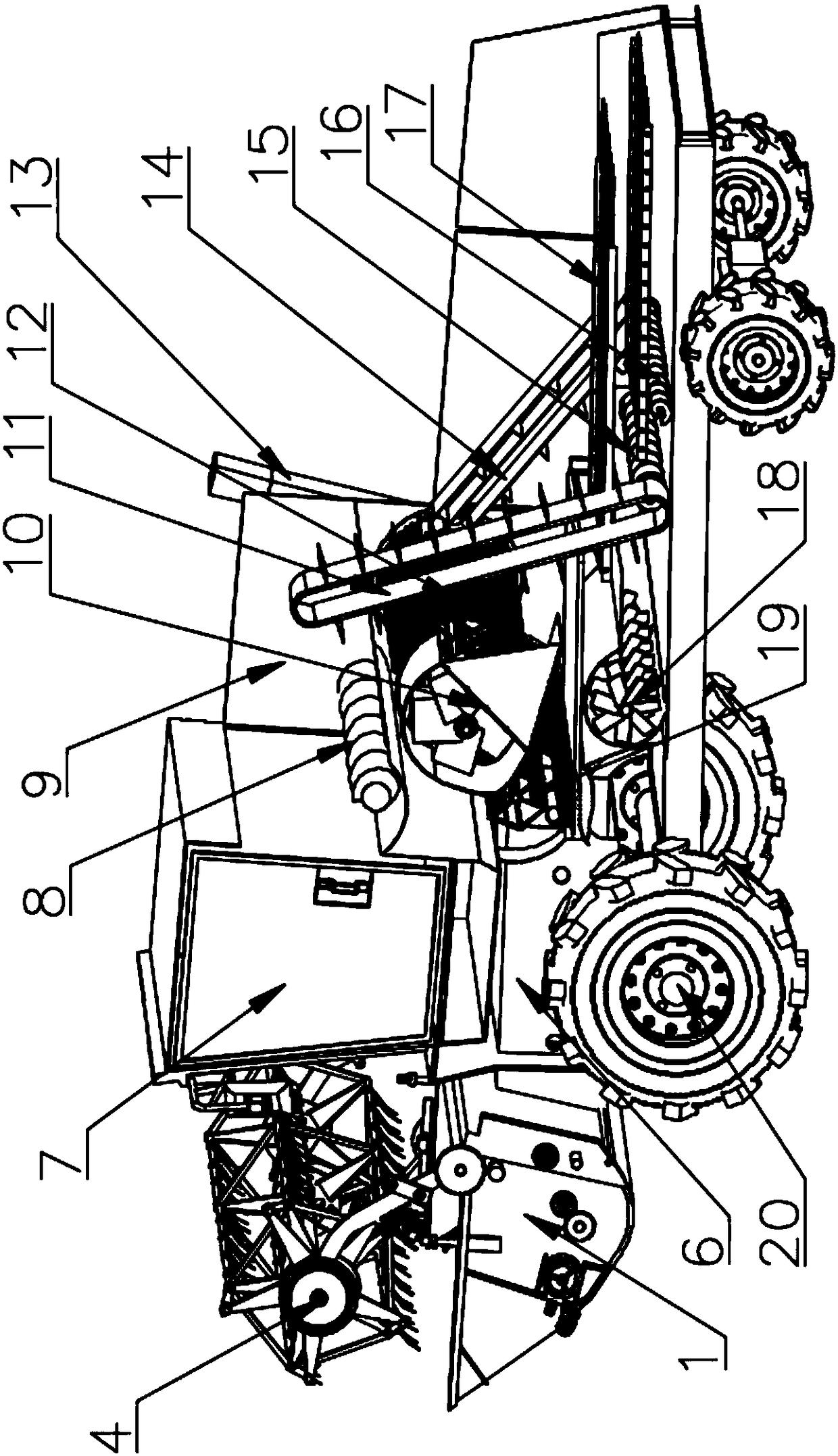

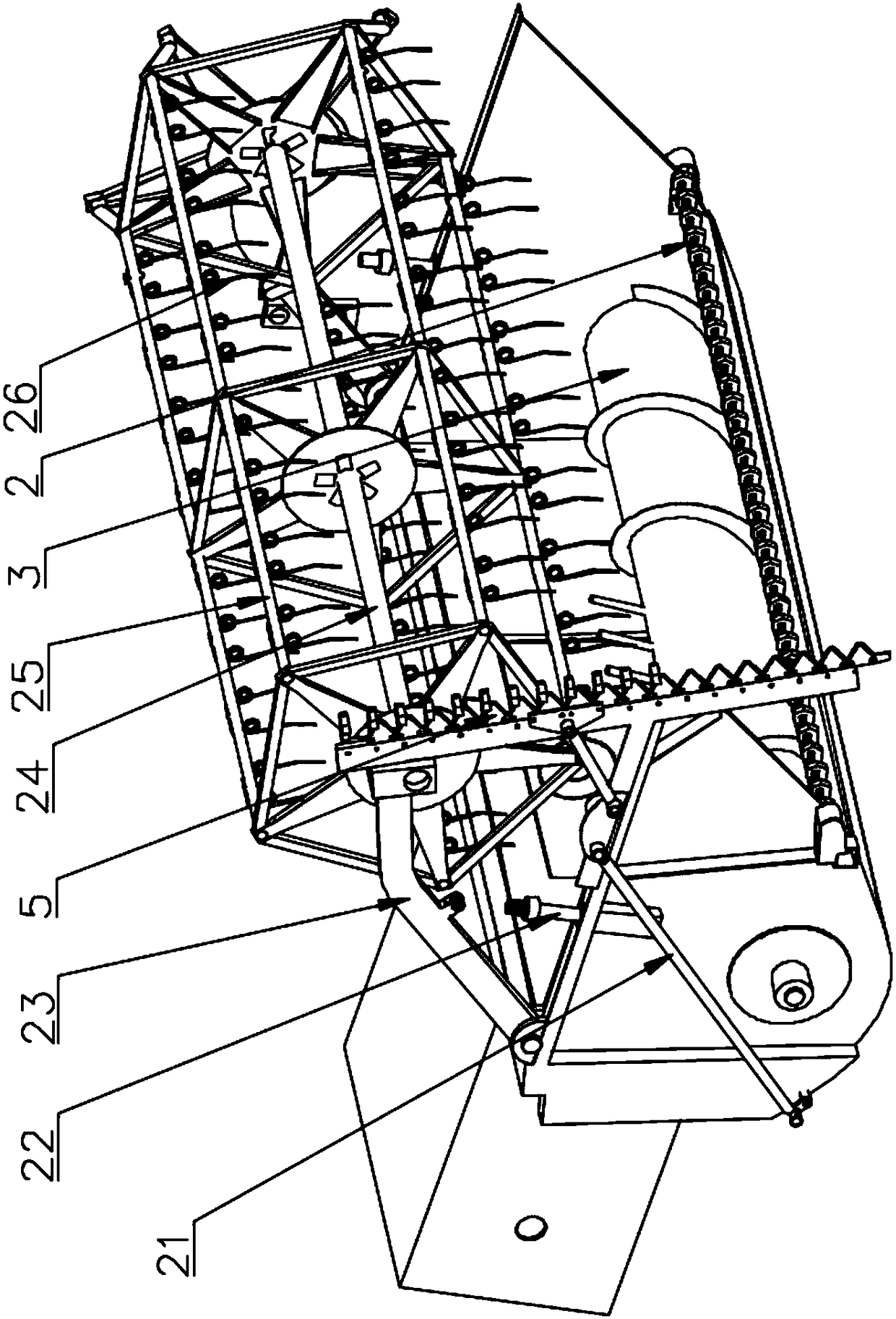

[0036] See details Figure 1 to Figure 7 The rapeseed combine harvester of the present embodiment includes a body 7, a header frame 1, a connecting bridge 6 between the body 7 and the header frame 1, a horizontal cutting knife 2 hinged at the front of the header frame 1, a cutting One-side vertical cutting knife 5 and its transmission mechanism 21, the eccentric reel 4 on the top of the header, the header conveying auger 3 inside the header frame 1 and the header lifting assembly of the header rear side plate, and It includes the walking wheels 20 below the machine body and the threshing assembly in the middle of the machine body. The straw chopper 10 and the cleaning system at the bottom of the threshing assembly include a centrifugal fan 18 , a shaking plate 58 and a vibrating screen 17 .

[0037] Before the operation, the manipulator passes the main hydraulic cylinder 28, the auxiliary hydraulic cylinder 29, the hydraulic device 22 and the hydraulic lifting rod 23 that cont...

Embodiment 2

[0041] See details Figure 2 to Figure 5 , the rapeseed combine harvester of this embodiment is aimed at the rapeseed planting mode in Northwest China and further explains the adjustment mechanism of the header and the eccentric reel in the first implementation case.

[0042] The unique climatic conditions and field location in Northwest China make the mechanical harvesting of rapeseed different from that in the southern region. It is required that the operating machine can harvest rapeseed at different heights and slopes by adjusting the control system. Described header lifting assembly is two groups, is positioned at the both sides of header 1 respectively, and each group of header lifting assembly comprises main hydraulic cylinder 28, auxiliary hydraulic cylinder 29 and main hydraulic cylinder limit hole 36, auxiliary hydraulic cylinder limit hole 39. The auxiliary hydraulic cylinder 29 is connected with the cylinder shell 27 of the main hydraulic cylinder 28 with bolts. Th...

Embodiment 3

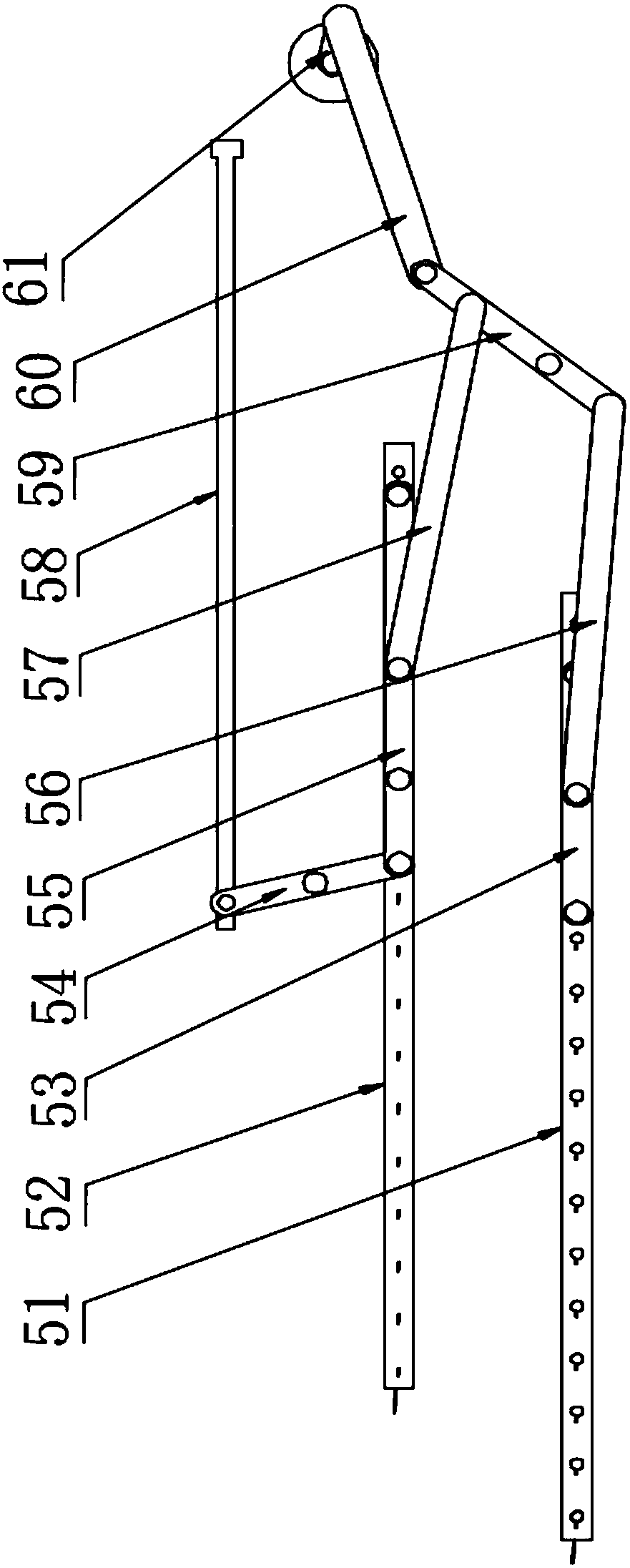

[0046] See details figure 1 and Image 6 It is the threshing part of the rapeseed combine harvester. The threshing assembly in this embodiment includes the first spike-toothed tangential flow drum 19 and the second mixed axial flow drum 11 located in the middle of the body. characteristics, determine that the threshing principle is mainly based on combing and impacting, and rubbing is supplemented (mainly for some semi-ripe green pods), so the tangential flow cylinder 19 selects the nail-toothed cylinder 46 based on combing and impacting, which can not only Improve the cleaning rate of rapeseed and use the grabbing characteristics of the nail teeth as an intermediate conveying device without transition to connect the second drum to improve work efficiency. The grain rod type 47 is mainly for rubbing and threshing, mainly for some semi-ripe green pods, and the rear half shaft is the nail-toothed type 49, which beats and combs the pods after rubbing. The type selection and des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com