Oxygen-enriched combustion device and method of solid fuel circulating fluidized bed

A circulating fluidized bed and solid fuel technology, applied in fluidized bed combustion equipment, combustion methods, combustion types, etc., can solve the problems affecting the absorption of furnace heat, the layout of boiler heating surfaces, and the volume reduction of tail flue, etc. , to achieve the effect of reducing boiler cost, facilitating capture and subsequent utilization, and reducing metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

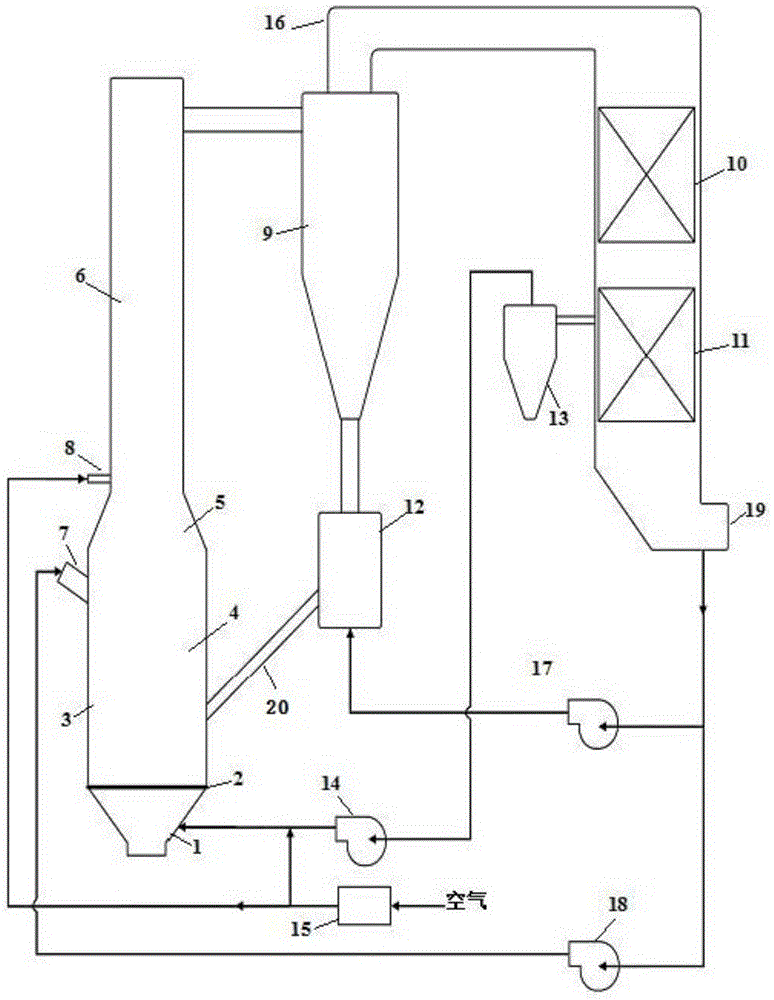

[0018] Such as figure 1 As shown, this embodiment discloses a partition control and multi-stage air distribution device for solid fuel fluidized bed oxygen-enriched combustion such as coal and biomass, including an air chamber 1 and an air distribution device 2 arranged above the air chamber 1 , the furnace 3 above the air distribution device 2, the furnace 3 is composed of three parts: the strong mixing zone 4 with a large lower cross-sectional area, the middle conical transition zone 5 and the quasi-flat flow zone 6 with a small upper cross-sectional area. Solid fuel such as coal or biomass and limestone feeding port 7 is provided in the upper part of zone 4, and a secondary air distribution pipe 8 is provided at the bottom of quasi-flat flow zone 6, and a high-temperature cyclone separator is connected to the upper part of quasi-flat flow zone 6 through pipes 9. The lower end of the high-temperature cyclone separator 9 is connected to the feeder 12, and the feeder 12 is con...

Embodiment 2

[0022] In this embodiment, the combustion device used is the same as that in Embodiment 1.

[0023] Mixed particles of coal powder and corn stalks (corn stalks account for 15% by volume) are used as fuel. During operation, the fuel and limestone are transported to the solid fuel and limestone feeding port 7 through the feeding device. into the furnace; the flue gas output by the high temperature cyclone separator 9 through the flue 16 with the heat exchanger 10 and the economizer 11 enters the medium temperature cyclone separator 13, and the flue gas output by the first flue gas circulation fan 14 is separated from the air Part of the oxygen output from the device 15 is mixed as the primary air; part of the oxygen output from the air separation device 15 is directly used as the secondary air; the flue gas output by the high-temperature cyclone separator 9 through the flue 16 passes through the second flue gas circulation fan 17 and the second flue gas circulation fan 17. Three...

Embodiment 3

[0026] In this embodiment, the combustion device used is the same as that in Embodiment 1.

[0027] The mixed fuel of pulverized coal and biomass molding particles (biomass mixed particles account for 30% by volume) is used as the fuel. During operation, the fuel and limestone are transported to the solid fuel and limestone feeding port 7 through the feeding device. Under the action, it is spread into the furnace; the flue gas output by the high-temperature cyclone separator 9 through the flue 16 with the heat exchanger 10 and the economizer 11 enters the medium-temperature cyclone separator 13, and the flue gas output by the first flue gas circulation fan 14 The gas is mixed with part of the oxygen output from the air separation device 15 and used as the primary wind; part of the oxygen output from the air separation device 15 is directly used as the secondary wind; the flue gas output by the high temperature cyclone separator 9 through the flue 18 is circulated through the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com