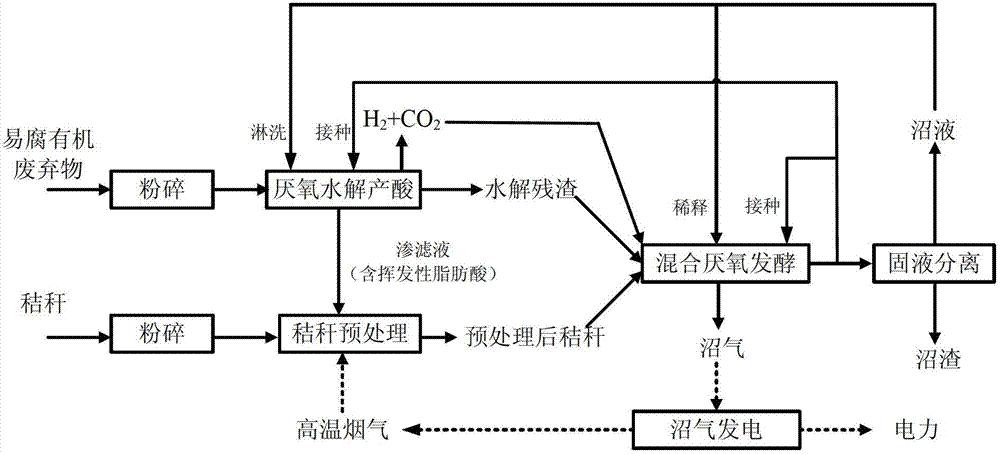

Method for producing methane through combination of perishable organic wastes and straws

A technology for producing biogas from organic waste, applied in waste fuel, fermentation, etc., can solve problems such as difficulty in finding sanitary landfill sites, low energy output efficiency, and high one-time investment, so as to avoid corrosion of equipment and pipelines, reduce Cost of pretreatment, effect of optimizing carbon-nitrogen ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Use fresh fruit and vegetable waste (moisture content 89%) as perishable organic waste, collect and remove impurities, and crush it to a particle size below 20mm for later use; use dry straw (moisture content 9%) as straw, and crush it to a particle size below 20mm for later use; Pack 50kg of crushed fruit and vegetable waste on the diafiltration packing of the solid percolation bed, add biogas fermentation inoculum, seal the solid percolation bed, control the pH value to 4.5 for anaerobic hydrolysis to produce acid, and take 1.5 kg from the solid-liquid every 4 hours The separated biogas slurry enters from the top of the solid percolation bed and rinses the fruit and vegetable waste through the water distributor, and the volatile fatty acids (formic acid, acetic acid, propionic acid, butyric acid, valeric acid, lactic acid, etc.) produced by hydrolysis are dissolved In biogas slurry, leachate is formed after passing through the diafiltration packing and the porous plate ...

Embodiment 2

[0031] Use fresh fruit and vegetable waste (moisture content 89%) as perishable organic waste, collect and remove impurities, and crush it to a particle size below 20mm for later use; use dry straw (moisture content 9%) as straw, crush it to a particle size below 20mm for later use; Load 100kg of crushed fruit and vegetable waste on the diafiltration packing of the solid percolation bed, add biogas fermentation inoculum, seal the solid percolation bed, control the pH value to 5 for anaerobic hydrolysis to produce acid, and take 3 kg every 3 hours for solid-liquid separation The final biogas slurry enters from the top of the solid percolation bed and rinses the fruit and vegetable waste through the water distributor. The volatile fatty acids (formic acid, acetic acid, propionic acid, butyric acid, valeric acid, lactic acid, etc.) produced by hydrolysis are dissolved in In the biogas slurry, leachate is formed after passing through the diafiltration packing and the porous plate s...

Embodiment 3

[0033] Use fresh kitchen waste (moisture content 76%) as perishable organic waste, collect and remove impurities, and crush it to a particle size below 20mm for later use; use dry straw (moisture content 9%) as straw, and crush it to a particle size below 20mm for later use; Take 100kg of crushed kitchen waste and put it on the diafiltration packing of the solid percolation bed, add biogas fermentation inoculum, seal the solid percolation bed, control the pH value of 6.5 for anaerobic hydrolysis to produce acid, take 4kg from the solid percolation bed every 3 hours The biogas slurry after liquid separation enters from the top of the reactor and washes the kitchen waste through the water distributor, and the volatile fatty acids (formic acid, acetic acid, propionic acid, butyric acid, valeric acid, lactic acid, etc.) produced by hydrolysis are dissolved In water, under the action of gravity, it passes through the diafiltration packing and the porous plate supporting the diafiltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com