New method for pre-treating raw materials for fermenting wheat straw biogas

A biogas fermentation and pretreatment technology, applied in fermentation, waste fuel, etc., can solve problems affecting the application of acid-base pretreatment, loss of dissolved organic matter, and subsequent utilization of biogas residues, so as to facilitate subsequent utilization and reduce pretreatment Cost, effects of avoiding inhibition and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

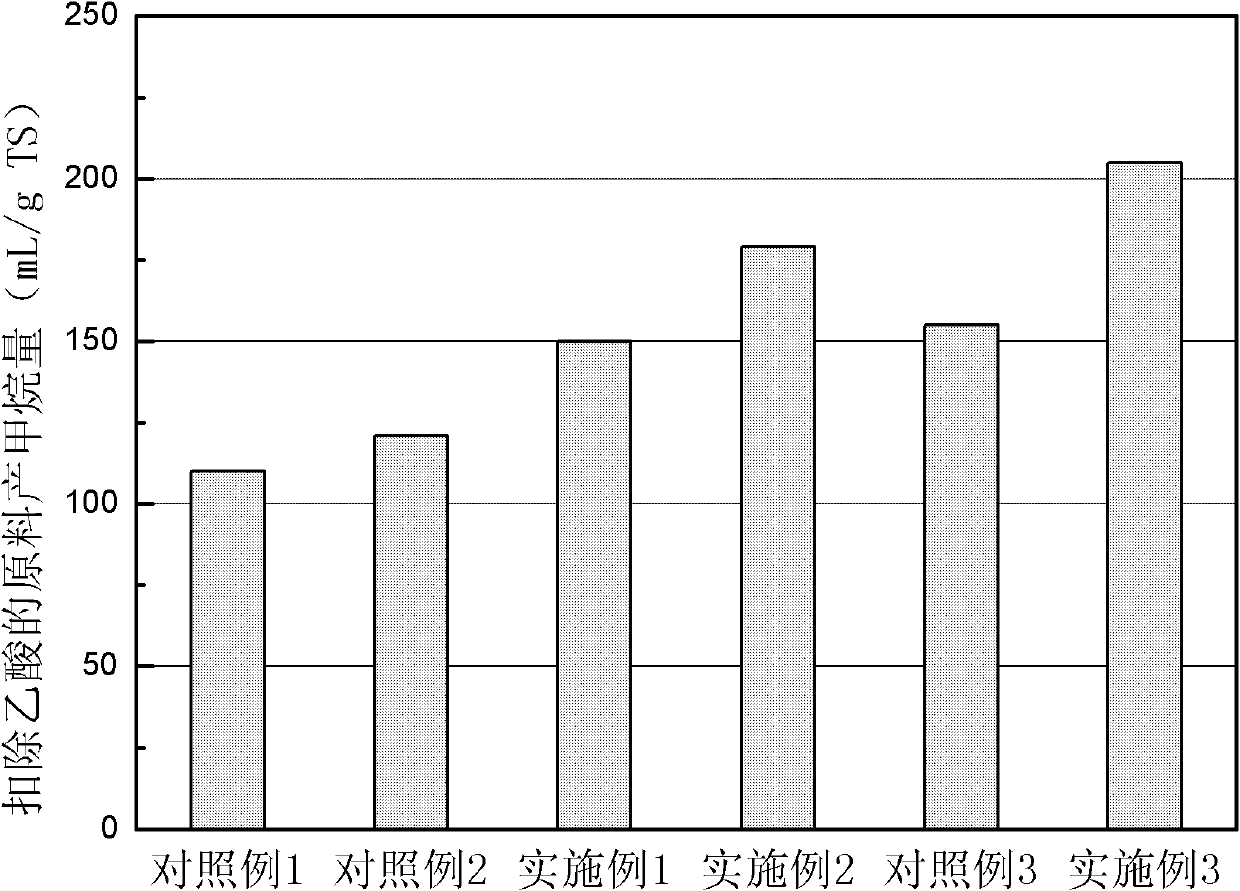

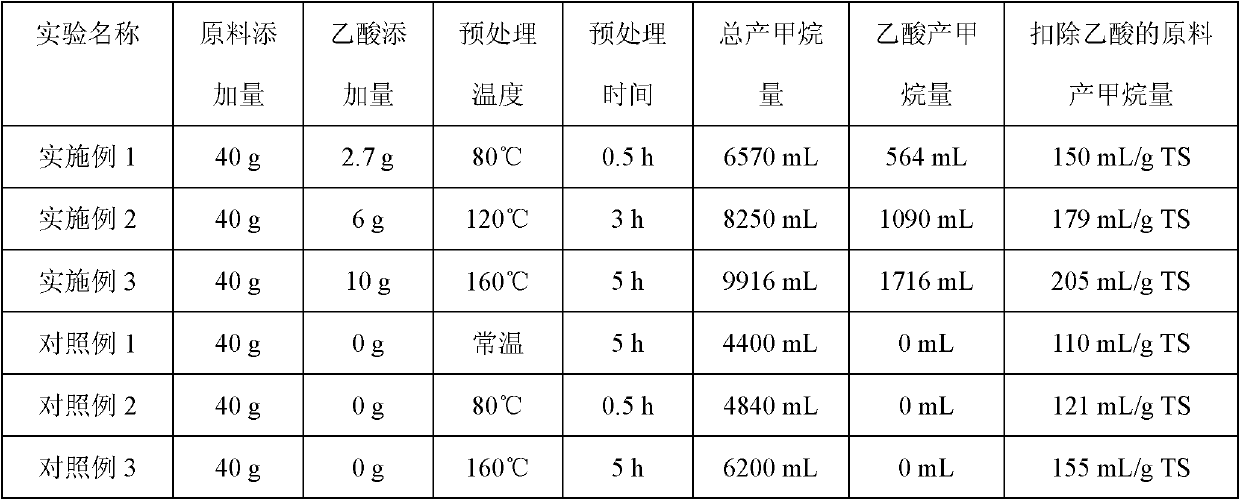

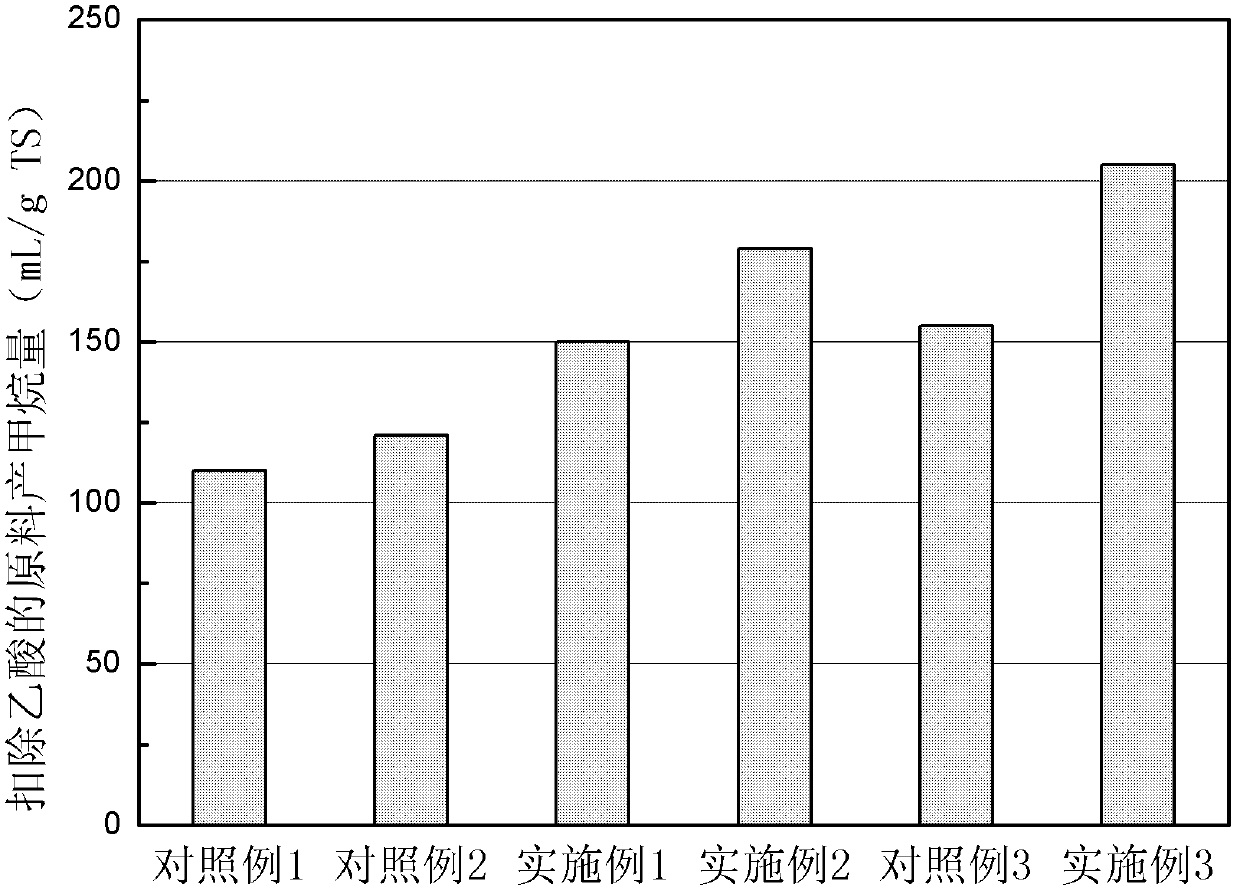

Embodiment 1

[0019] Rice straw is used as raw material, and acetic acid is used as pretreatment agent. Grind the dry rice straw to a particle size of about 0.5-1cm, take 40g and add it to the pretreatment reactor, add 2.7g acetic acid, add 457g water to adjust the dry matter concentration of the rice straw to 8%, stir the mixed material evenly, and seal the pretreatment reaction The device is used for heating and soaking pretreatment, the pretreatment temperature is controlled at 80°C, and the pretreatment time is 0.5h.

[0020] The pretreated rice straw, acetic acid, and water mixture are taken out and cooled, and put into a biogas fermentation reactor to inoculate for medium temperature (37°C) anaerobic fermentation. In order to adjust the carbon-nitrogen ratio of the fermentation raw materials, nitrogen-rich kitchen waste biogas fermentation is used The residue was used as an inoculum, and a small amount of ammonium bicarbonate was added at the same time. The fermentation time was 25 da...

Embodiment 2

[0022] Rice straw is used as raw material, and acetic acid is used as pretreatment agent. Grind the dry rice straw to a particle size of about 0.5-1cm, take 40g and add it to the pretreatment reactor, add 6g of acetic acid, add 287g of water to adjust the dry matter concentration of the rice straw to 12%, stir the mixed material evenly, and seal the pretreatment reactor Carry out heating and soaking pretreatment, control the pretreatment temperature to 120°C, and the pretreatment time to 3h.

[0023] The pretreated rice straw, acetic acid, and water mixture are taken out and cooled, and put into a biogas fermentation reactor to inoculate for medium temperature (37°C) anaerobic fermentation. In order to adjust the carbon-nitrogen ratio of the fermentation raw materials, nitrogen-rich kitchen waste biogas fermentation is used The residue was used as the inoculum, and a small amount of ammonium bicarbonate was added at the same time. The fermentation time was 25 days, and the cum...

Embodiment 3

[0025] Rice straw is used as raw material, and acetic acid is used as pretreatment agent. Grind the dry rice straw to a particle size of about 0.5-1cm, take 40g and add it to the pretreatment reactor, add 10g of acetic acid, add 216g of water to adjust the dry matter concentration of the rice straw to 15%, stir the mixed material evenly, and seal the pretreatment reactor Carry out heating and soaking pretreatment, control the pretreatment temperature to 160°C, and the pretreatment time to 5h.

[0026] The pretreated rice straw, acetic acid, and water mixture are taken out and cooled, and put into a biogas fermentation reactor to inoculate for medium temperature (37°C) anaerobic fermentation. In order to adjust the carbon-nitrogen ratio of the fermentation raw materials, nitrogen-rich kitchen waste biogas fermentation is used The residue was used as the inoculum, and a small amount of ammonium bicarbonate was added at the same time. The fermentation time was 25 days, and the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com