Intelligent classified winding device and method for cable production

A winding device and cable technology, applied in transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the lack of structural devices for automatic protection of cables, lack of cable cleaning structures, and friction between cables and other issues to achieve the effect of protecting stability, improving safety and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

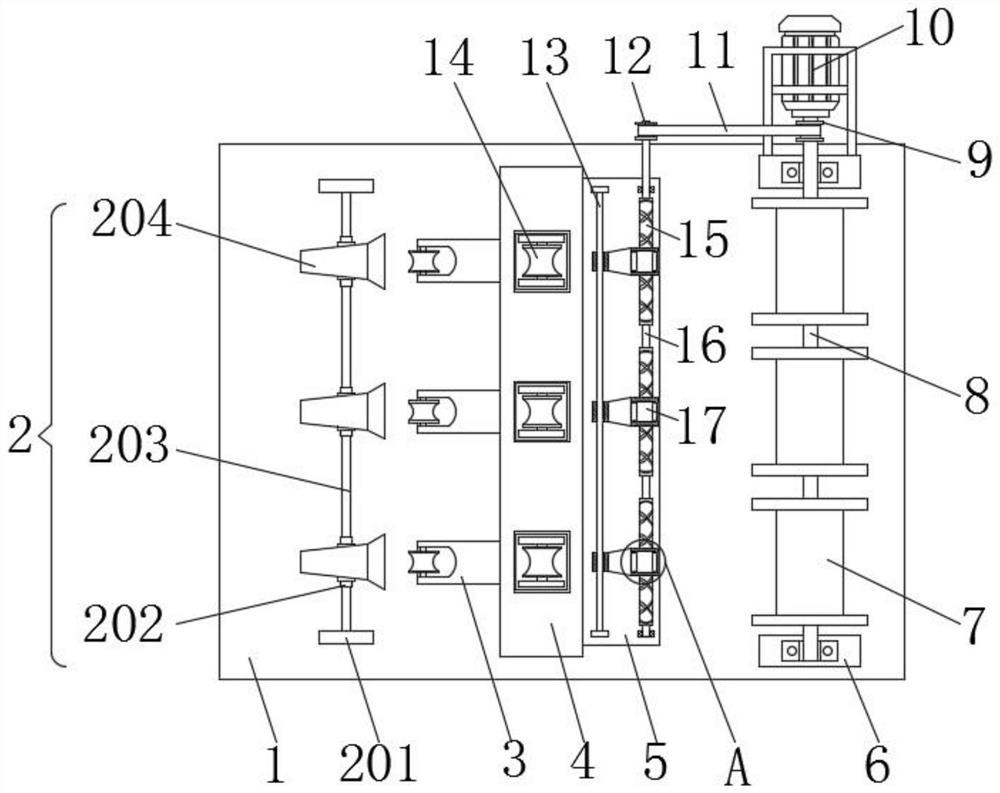

[0050] Embodiment 1: as figure 1 and 6 As shown, when the cable passes through the inside of the cleaning compartment 204, the cable is pulled to drive both sides of the cleaning compartment 204 to rotate around the connecting axis A203, so that the extrusion force on the cable during the winding process is reduced. To the minimum, the direction of the pulling force it receives is basically consistent with the displacement direction of the winding.

Embodiment 2

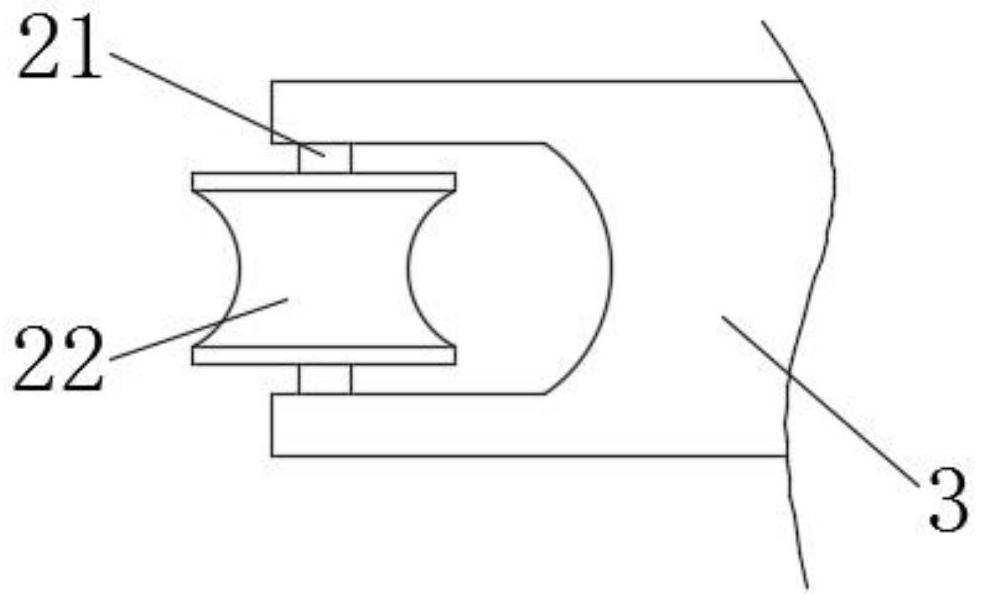

[0051] Embodiment 2: as figure 1 , 3 , 5 and 6, when the cables are wound around the outer sides of the two sets of pulleys B22, the cables are subjected to the tension of the winding, and then the two sets of pulleys B22 are squeezed to generate friction, and the two sets of pulleys are driven by the friction The B22 rotates, and the rotation of the pulley B22 ensures that the cable is always in a tight state and the normal winding of the cable.

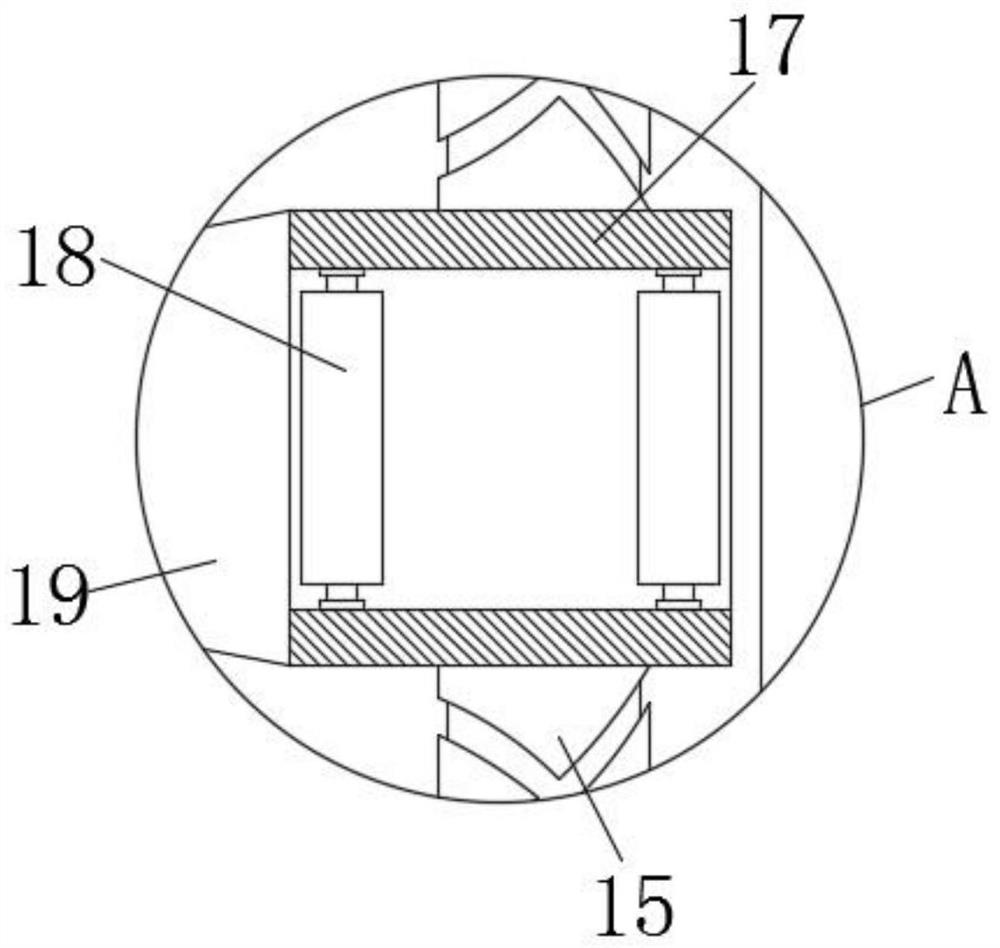

[0052] Working principle: The device provides power for the driving motor 10 through an external power supply. When the device is in use, the driving motor 10 provides power to drive the transmission shaft B8 and the pulley A9 to rotate, and the transmission shaft B8 drives the coil spring 20 and the winding reel 7 Carry out operation to rewind the cable, and at the same time pull the pulley B12 to rotate through the pulley A9 electric transmission belt 11, thereby driving the reciprocating screw 15 connected to the connecting shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com