Patents

Literature

42results about How to "Avoid rubbing against each other" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

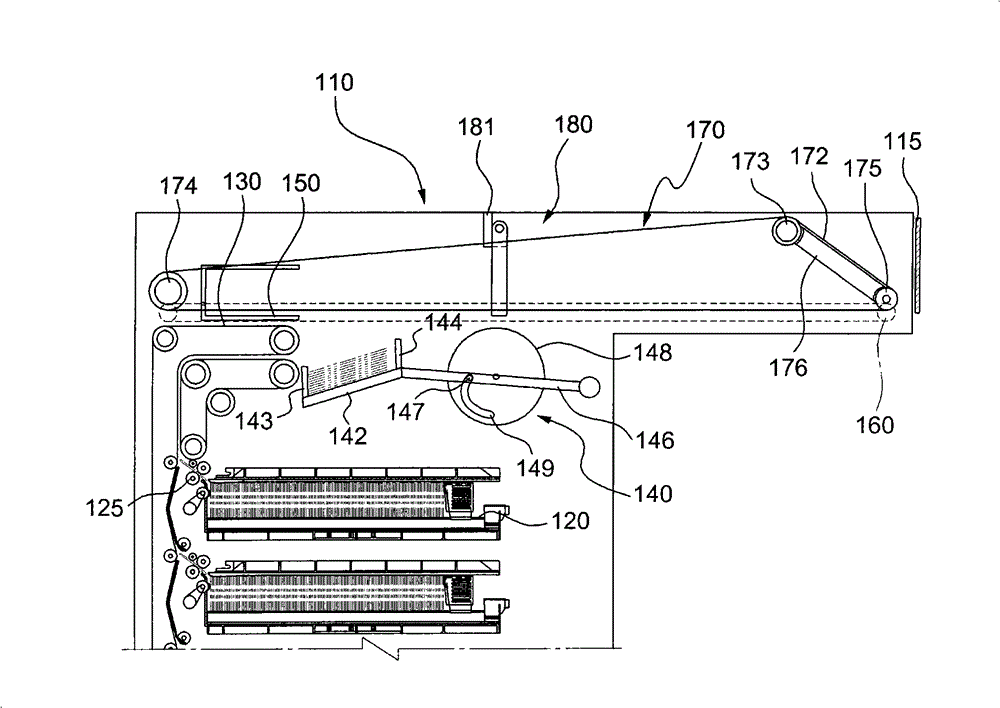

Cash transaction machine

ActiveCN101470917AAvoid rubbing against each otherPaper-money handling devicesCoin/currency accepting devicesEngineeringClutch

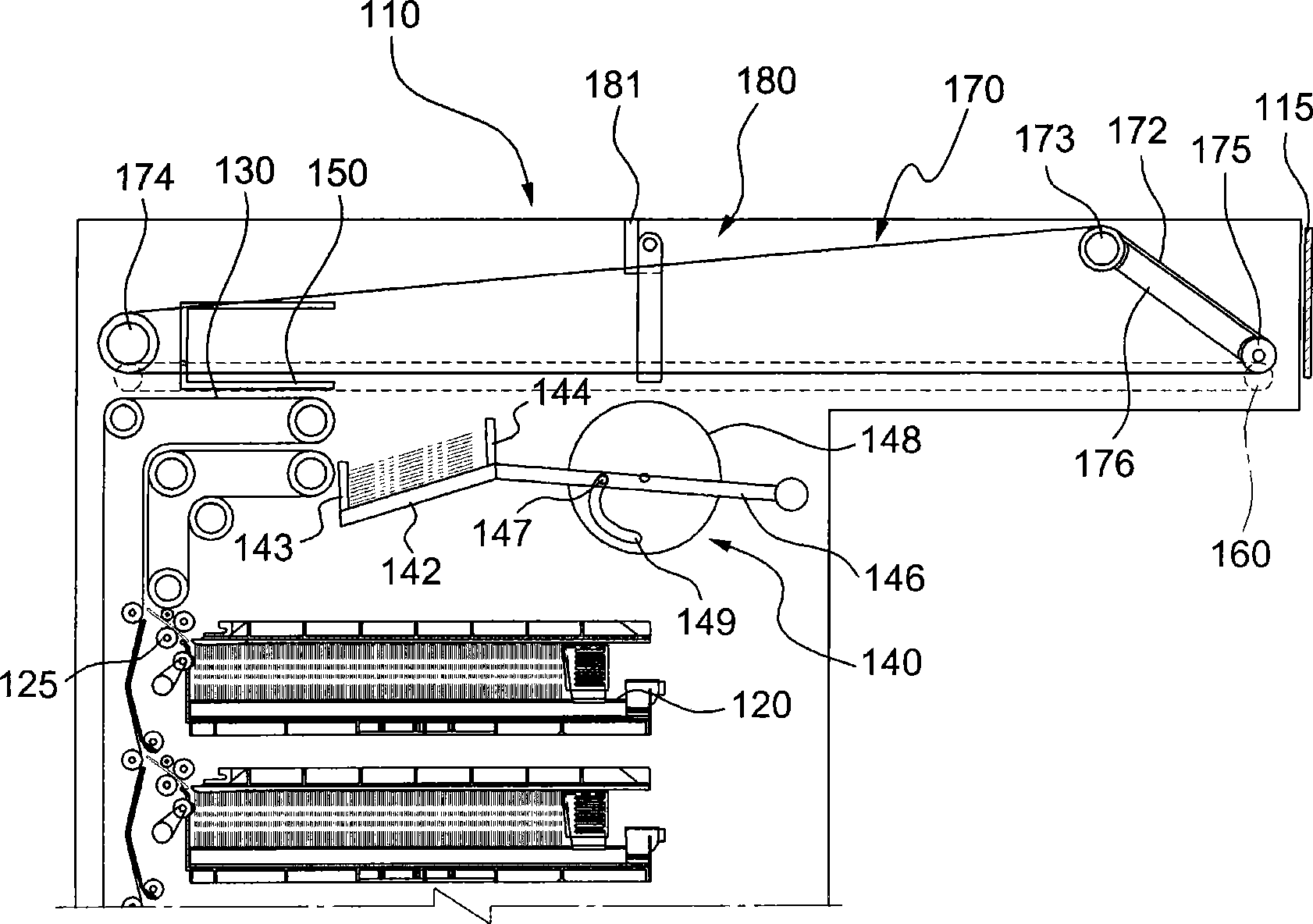

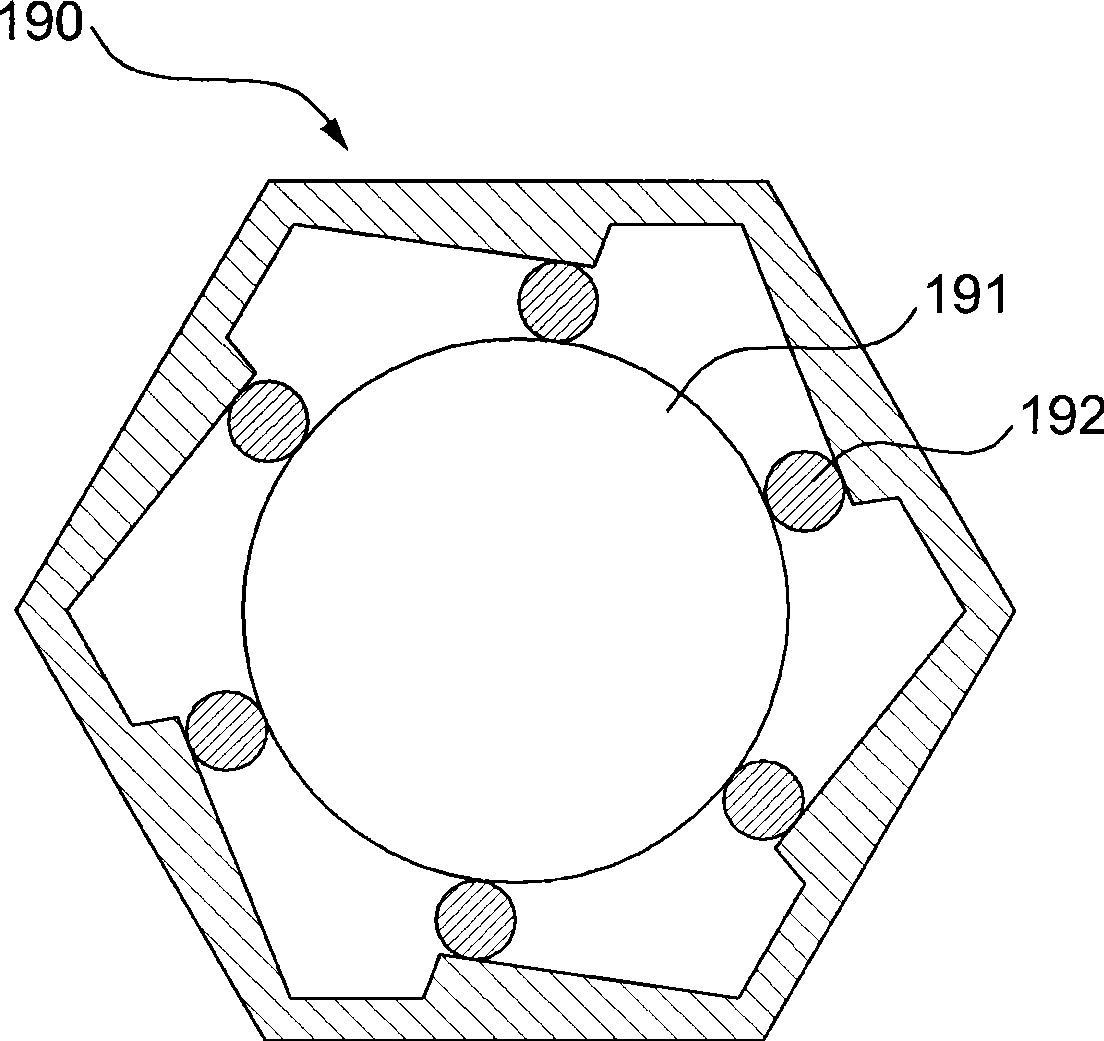

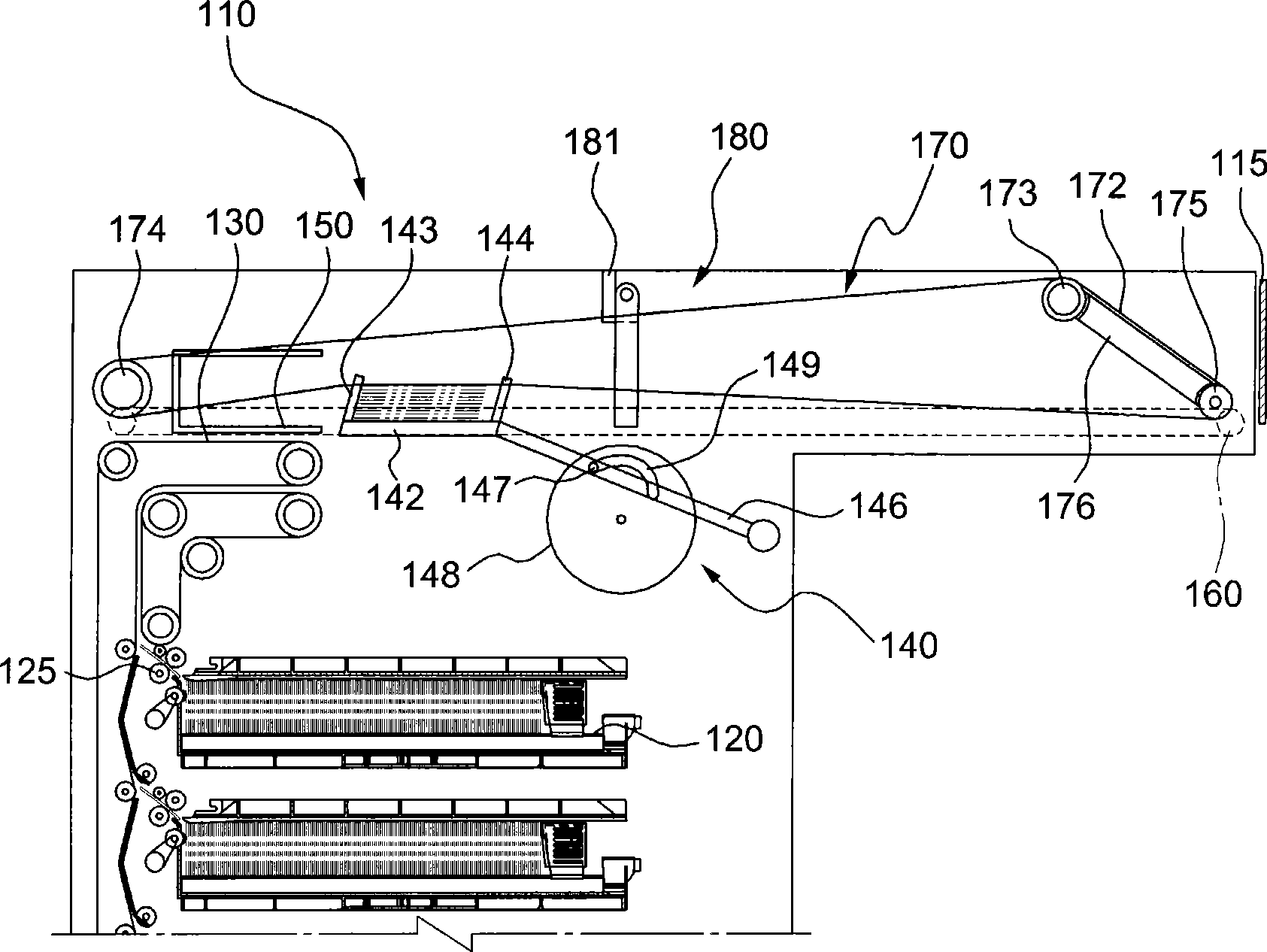

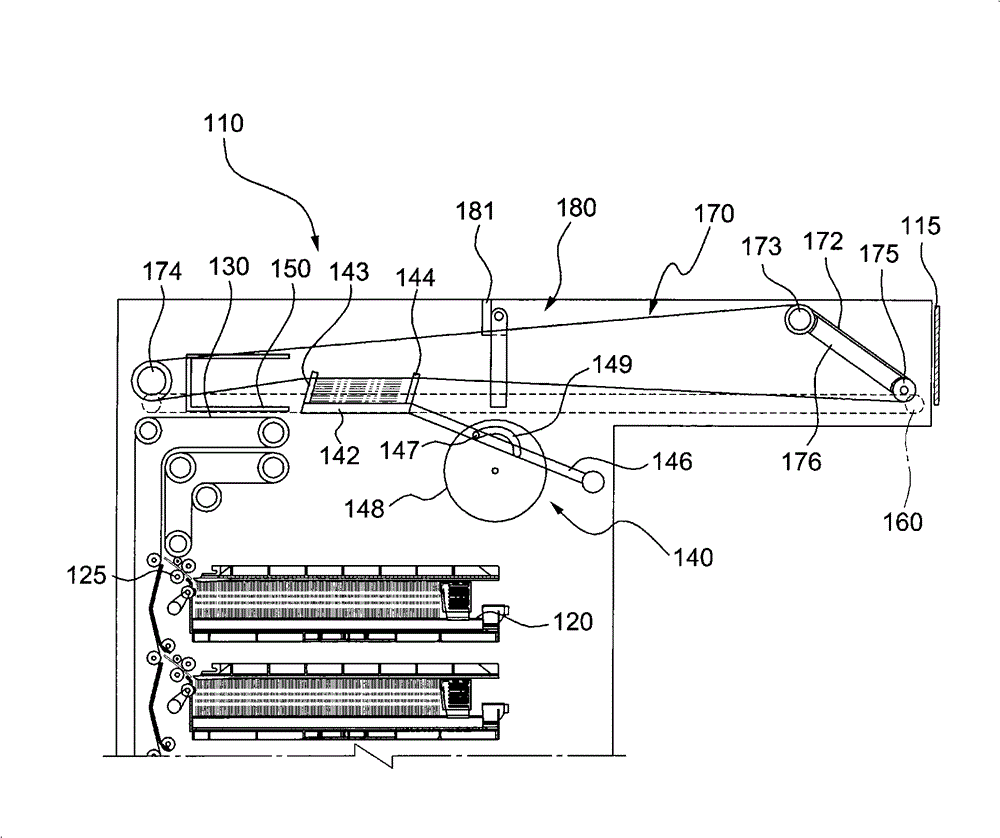

Provided is a cash transaction machine including a temporary stack portion. The cash transaction machine includes: a carriage receiving a paper medium stacked in the temporary stack portion; a driving belt transferring the carriage to a medium outlet; a pressing belt pressing the paper medium being transferred by the carriage in interoperation with the driving belt; a plurality of guide rollers being provided along a travel path of the carriage to define a travel path of the driving belt and a travel path of the pressing belt; and a one-way clutch adjusting an interoperating state between thedriving belt and the pressing belt to prevent a friction from occurring between the pressing belt and the paper medium while the paper medium is being loaded to the carriage.

Owner:NAUTILUS HYOSUNG

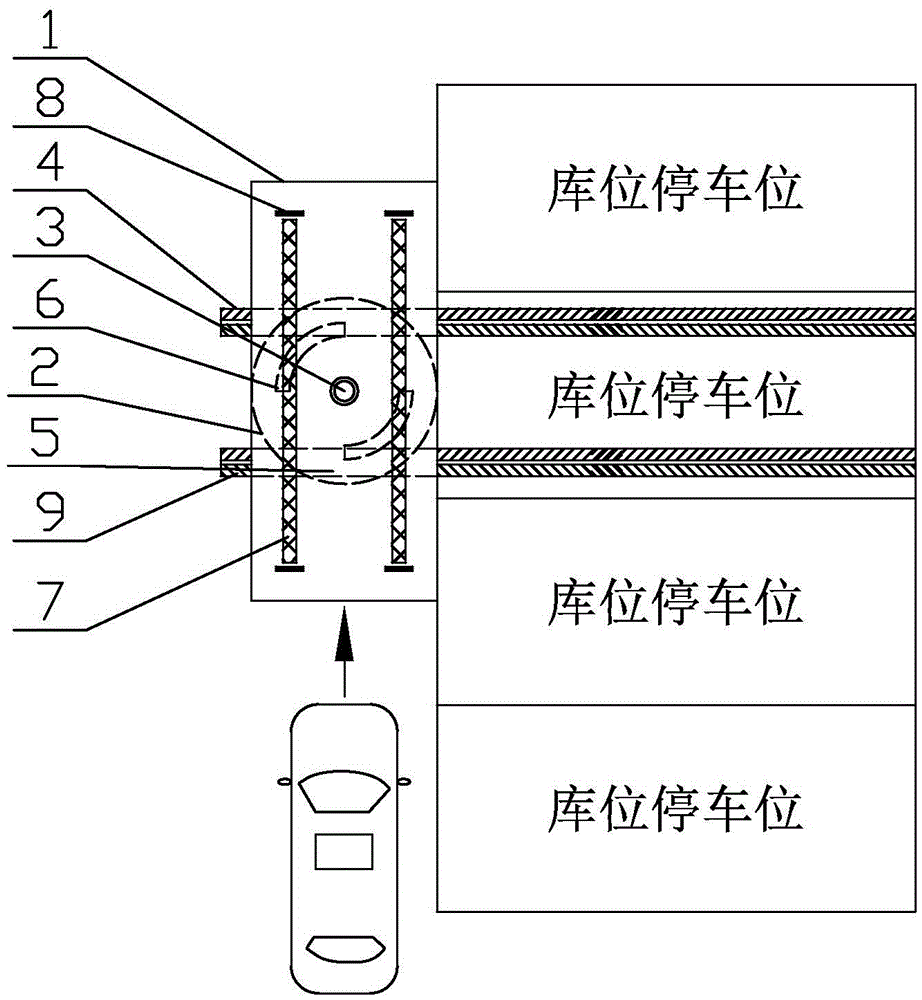

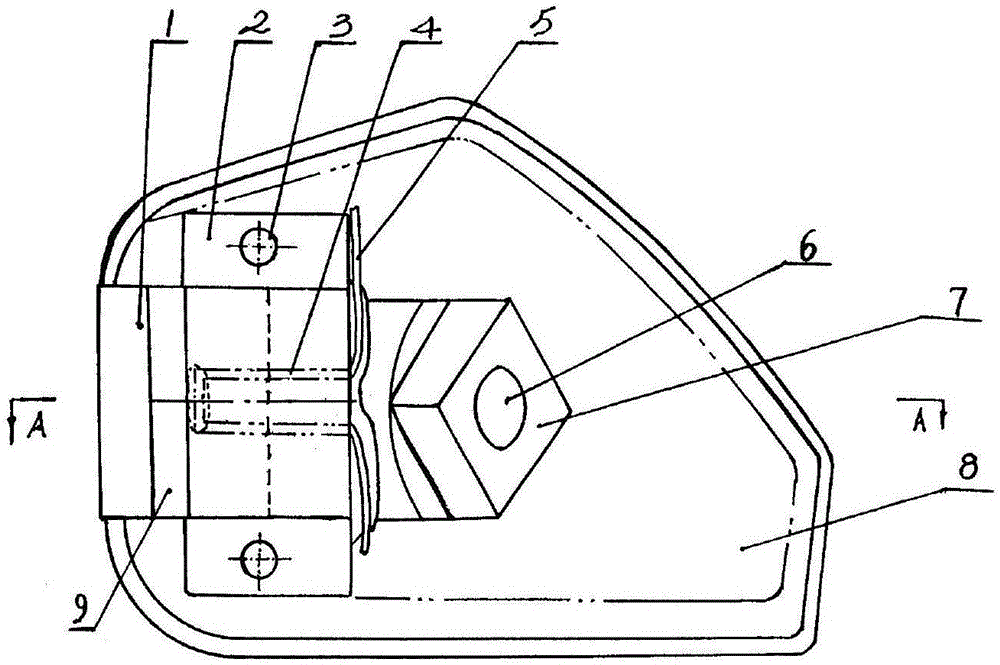

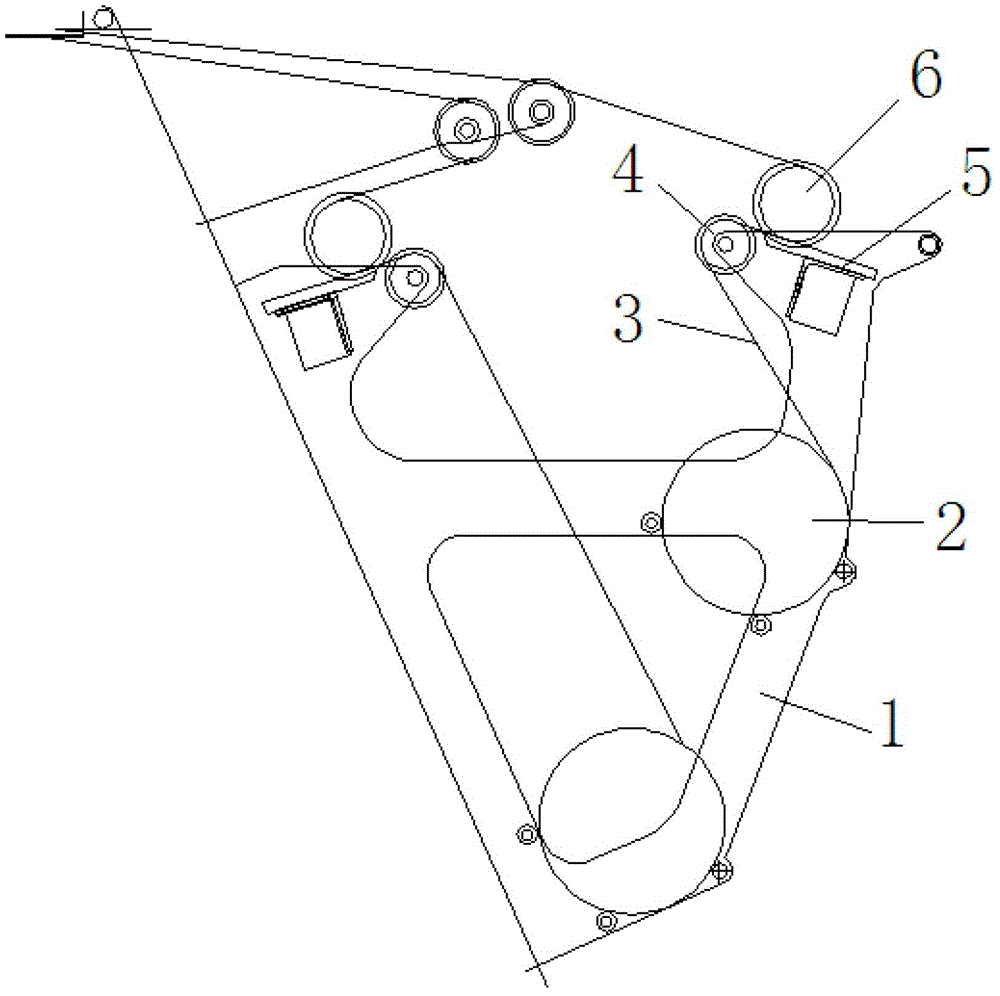

Parking device suitable for parking garage or space

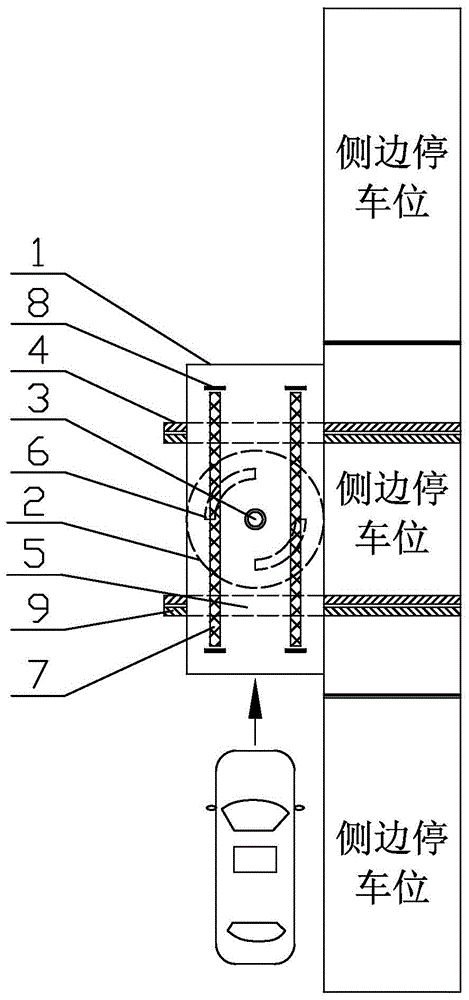

The invention discloses a parking device suitable for a parking garage or space. The device comprises a parking mechanism and a translational sliding mechanism, wherein the translational sliding mechanism is used for the parking mechanism to slide back and forth from the entrance / exit side of a rectangular parking space to the interior of the rectangular parking space; the parking mechanism consists of a parking plate and a guide plate; the parking plate and the guide plate are longitudinally connected integrally by arranging a rotary shaft bearing in a geometric center; the parking plate can rotate clockwise or anticlockwise on the plane of the guide plate by taking the rotary shaft bearing as a rotary center; the translational sliding mechanism consists of at least two sliding rails arranged in parallel and pulleys matched with the sliding rails; the sliding rails are embedded and connected to the ground; the sliding rail effect end of the top of each sliding rail is flush with the ground surface; and the pulleys are fixedly connected to the bottom surface of the guide plate. According to the parking device, the problem of difficulty in parking can be effectively solved and a driver can be assisted in accurately driving a car to a specified parking space or garage more conveniently and quickly during parking; and therefore, the parking device is especially suitable for drivers unskilled in driving technique.

Owner:刘冲

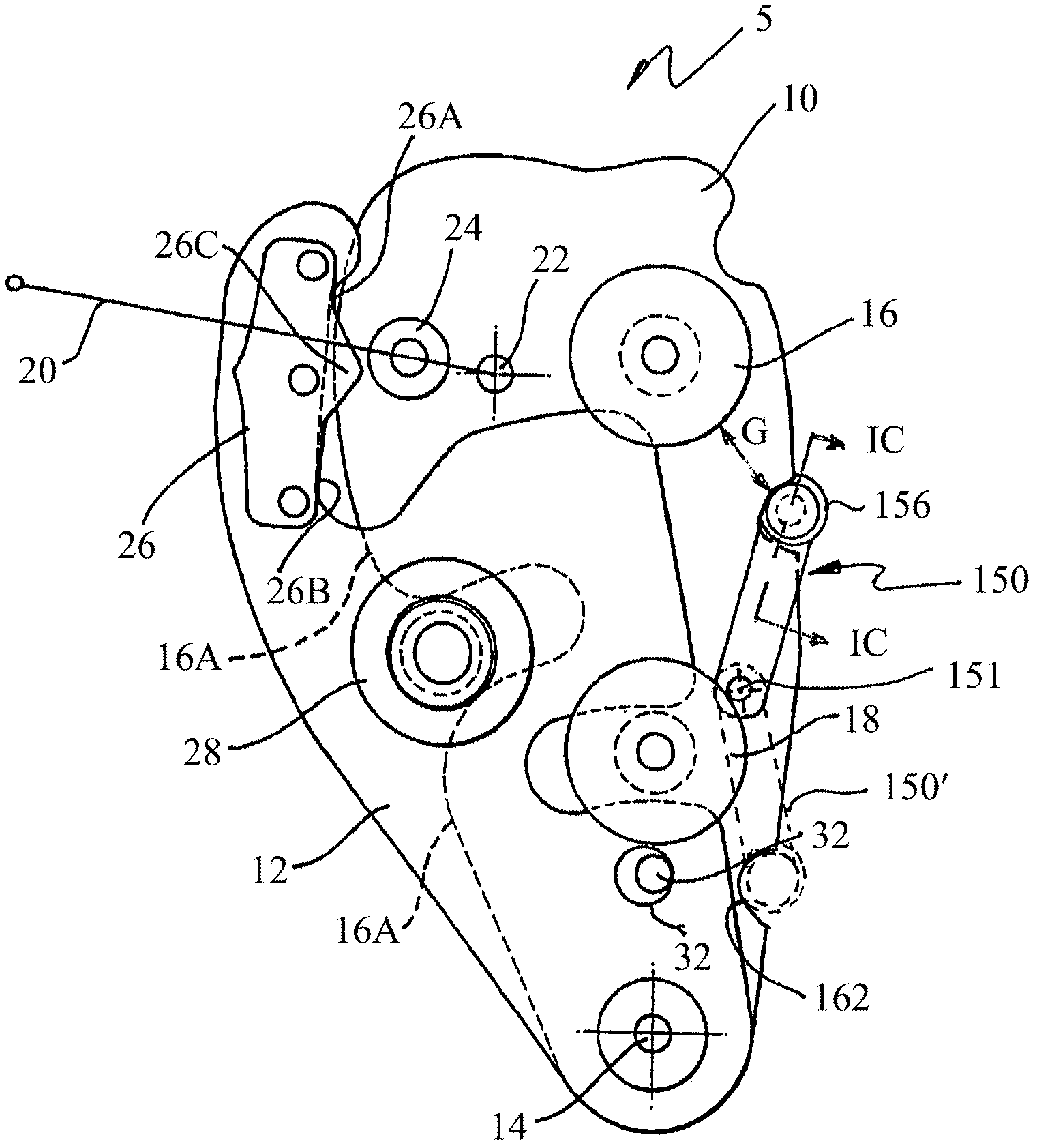

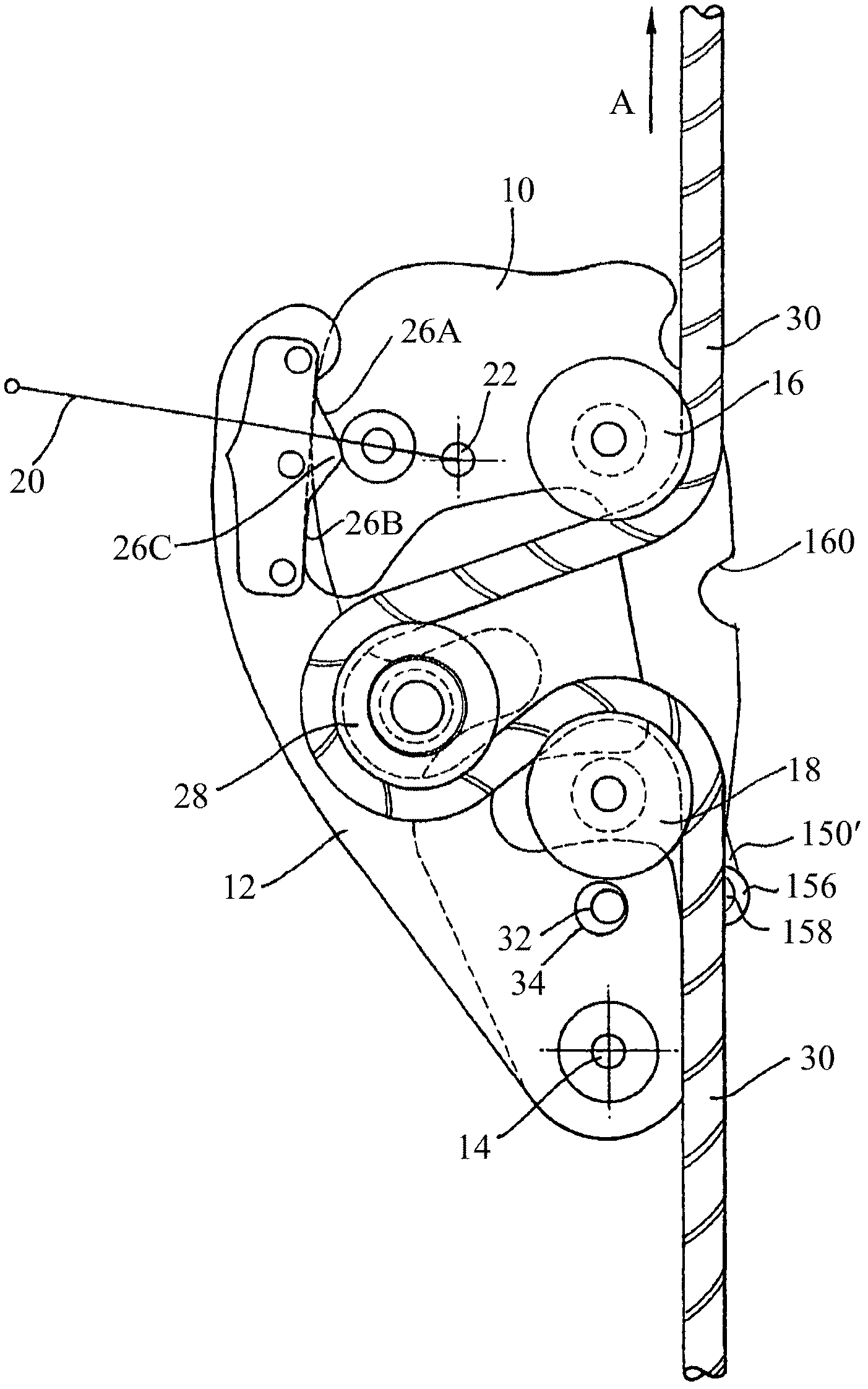

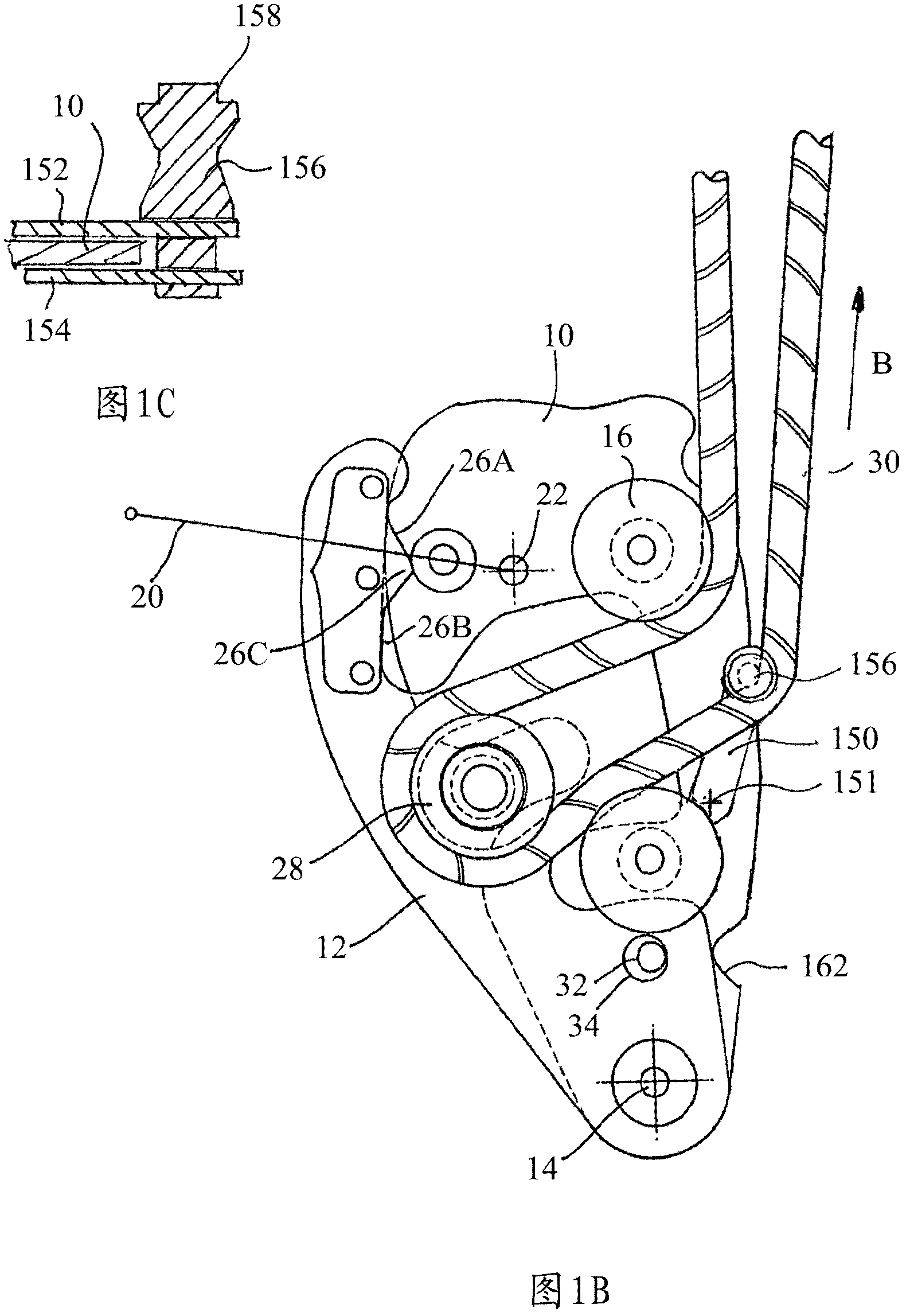

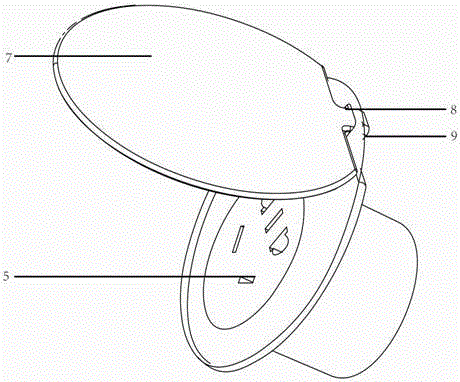

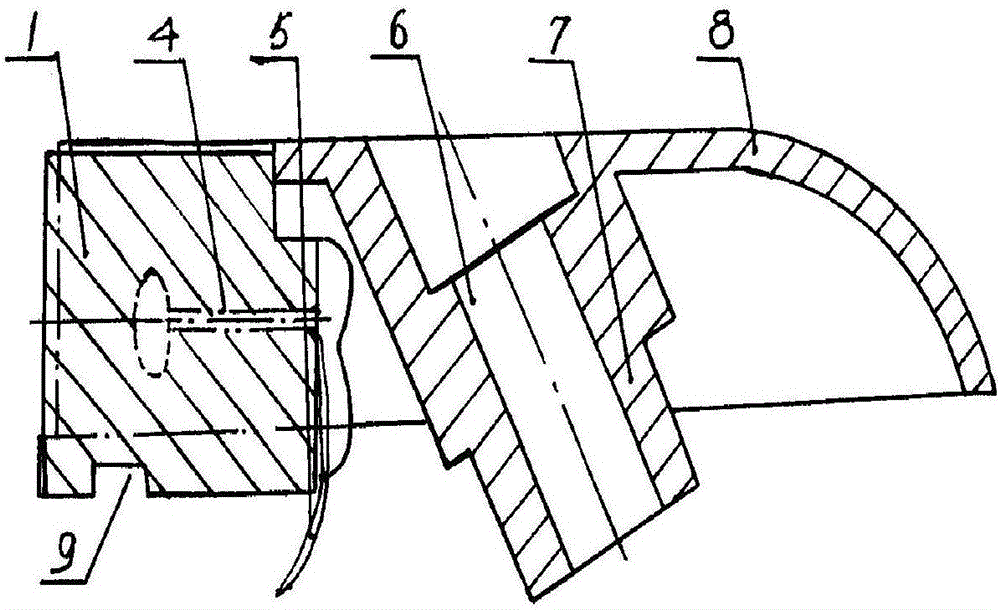

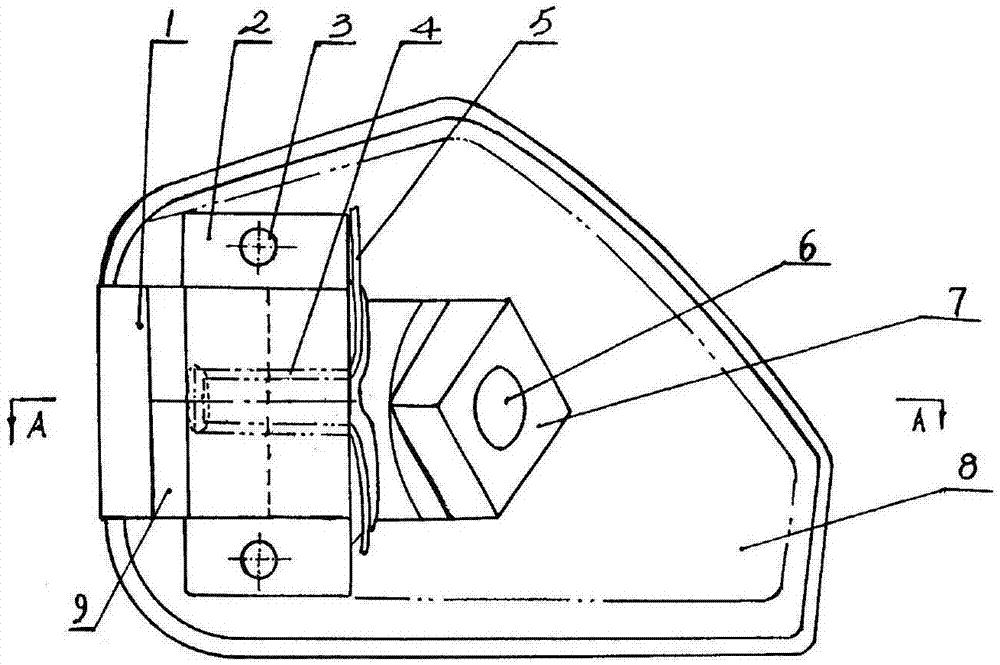

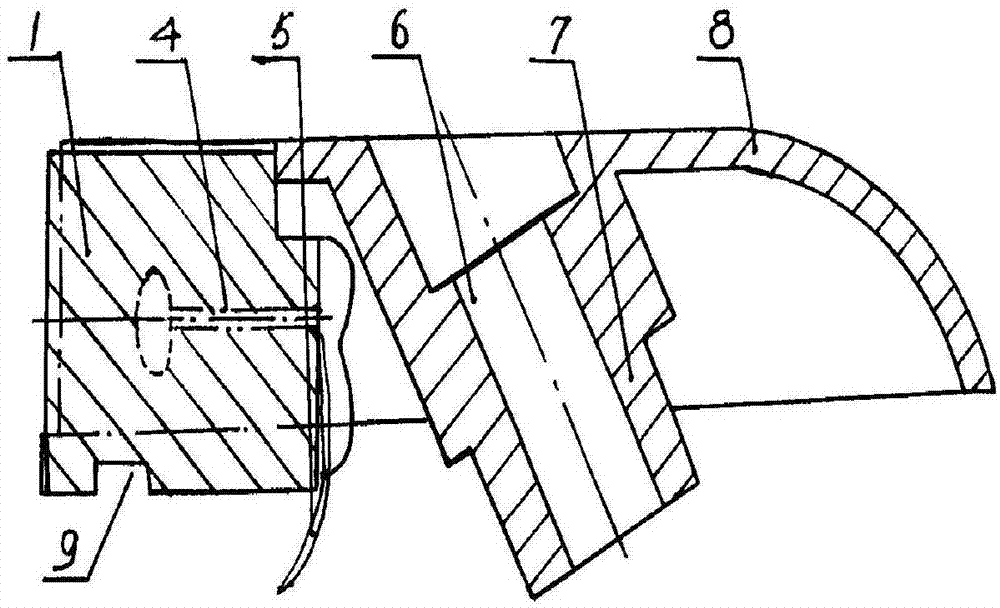

Descender with self- acting brake

InactiveCN102821816AAvoid rubbing against each otherMountaineeringBuilding rescueEngineeringMechanical engineering

A descender (5) for use in abseiling or belaying, comprising a base (10) connected to a harness or the like, with first (16) and second (18) spaced projections engaging a rope, the projections (16, 18) both extending normal to the base (10); an arm (12) pivotally mounted to the base (10) at a pivot axis (14), the arm (12) having a third projection (28) for engaging a rope, the projection (28) extending parallel to the pivot axis (14) and being located so that when the arm (12) is pivoted towards the base (10), the third projection (28) is located between the first (16) and second (18) spaced projections, wherein a fourth projection (156) disposed generally between the first (16) and second (18) projections and adjacent an edge of the base (10) separates a portion of rope passing into the descender (5) and around the first (16) and third (18); projections from the portion of the same rope passing out of the descender (5) between the third (28) and second (18) projections.

Owner:CAPITAL SAFETY GROUP AUSTRALIA

Intelligent classified winding device and method for cable production

The invention discloses an intelligent classified winding device and method for cable production. The device comprises a base; one side of the top of the base is provided with a cleaning assembly; the middle part of the top of the base is provided with a pressure reduction bin body; the top of one side of the pressure reduction bin body is uniformly provided with three groups of support frames A and support frames B; the supporting frames A are located over the supporting frames B; and a connecting shaft C is arranged on the inner side of one end of each supporting frame A and the inner side of one end of the corresponding supporting frame B. Through mutual cooperation of a transmission shaft B, coil springs, wire spools, pulleys A, supporting rods, pressing blocks, sliding blocks, sliding grooves, pressing switches, springs and limiting plates, under the condition that the cable encounters instantaneous jamming or tension increase during emergent winding, the tension generated on a cable can be absorbed and relieved; and the stability of the structure of the winding device is also protected while the cable is protected from being snapped, so that the service life of the device is prolonged, and the safety is improved.

Owner:欧耐特线缆集团有限公司

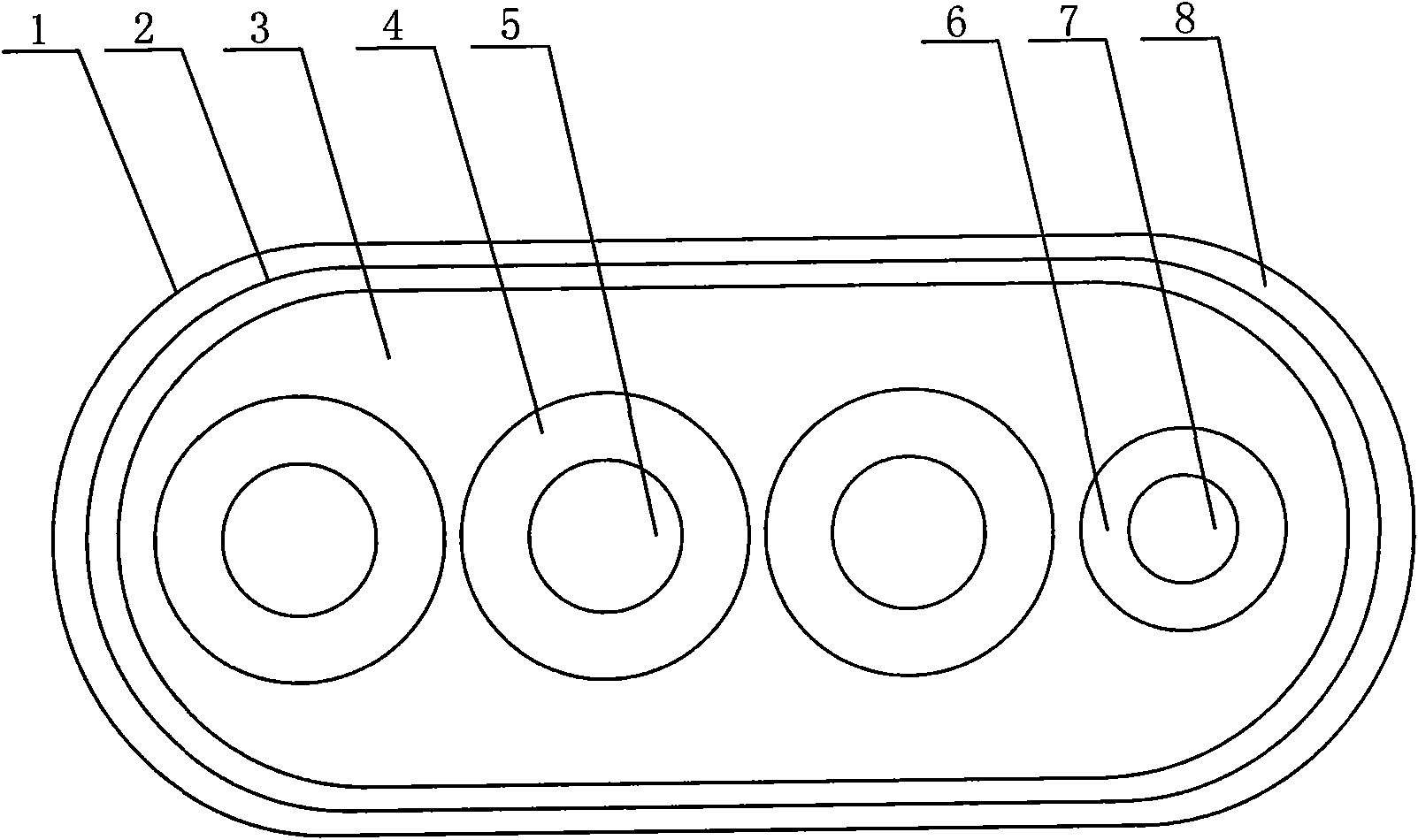

Corrosion prevention, high temperature resistance, steel wire armored and tearing resistance flat cable

InactiveCN101604561AAvoid erosionHigh strengthFlat/ribbon cablesInsulated conductorsEpoxyGlass fiber

The invention discloses a corrosion prevention, high temperature resistance, steel wire armored and tearing resistance flat cable. A protective layer is arranged outside a protective sleeve and can prevent a conductor and a rubber protective sleeve from being damaged by higher tearing force during the reciprocating dragging of the flat cable, wherein the protective layer comprises steel wire woven armor formed by weaving multiple strands of galvanized steel wires and an external fiber coating layer arranged outside the steel wire woven armor, and spaces among the protective sleeve, the steel wire woven armor and the external fiber coating layer are filled with binders. The steel wire woven armor is made of galvanized steel wire, and has favorable mechanical property, namely favorable tensile strength and tearing resisting strength; the external fiber coating layer is made of fibre glass, and can provide favorable properties of high temperature resistance and corrosion prevention; and the binders prepared from epoxide resin can prevent the mutual friction of the protective sleeve, the steel wire woven armor and the external fiber coating layer, enhance the integral strength of the protective sleeve and prevent outside corrosive liquid from corroding the protective sleeve.

Owner:宜昌华润红旗电缆有限公司

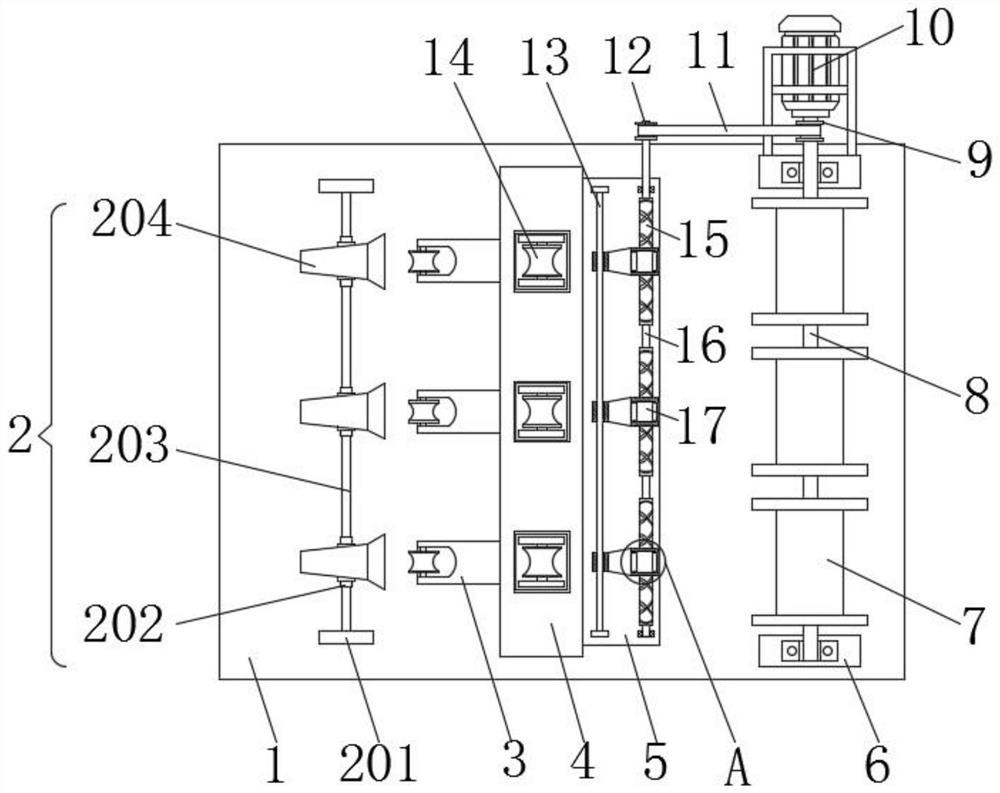

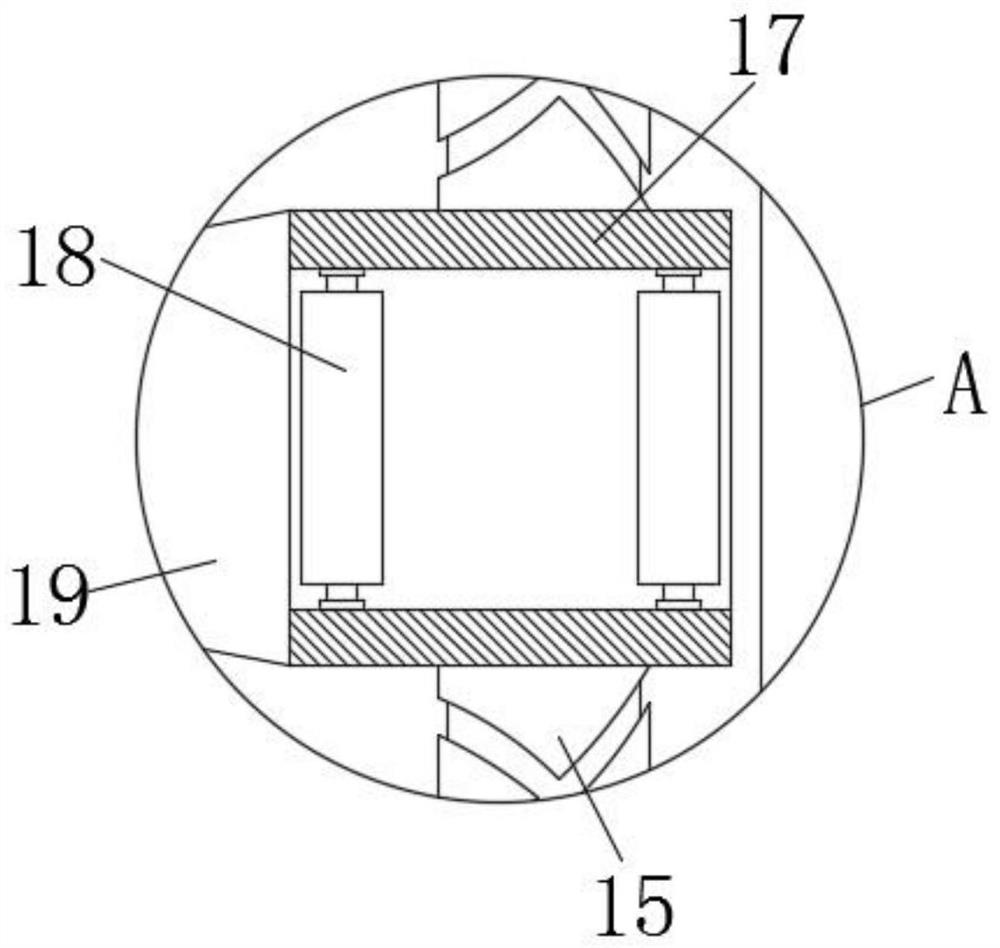

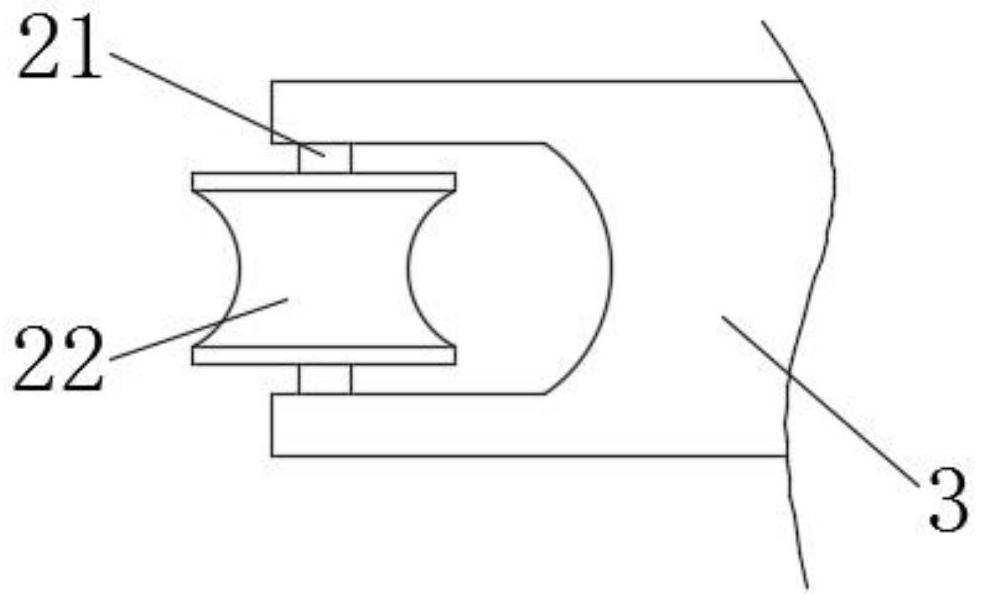

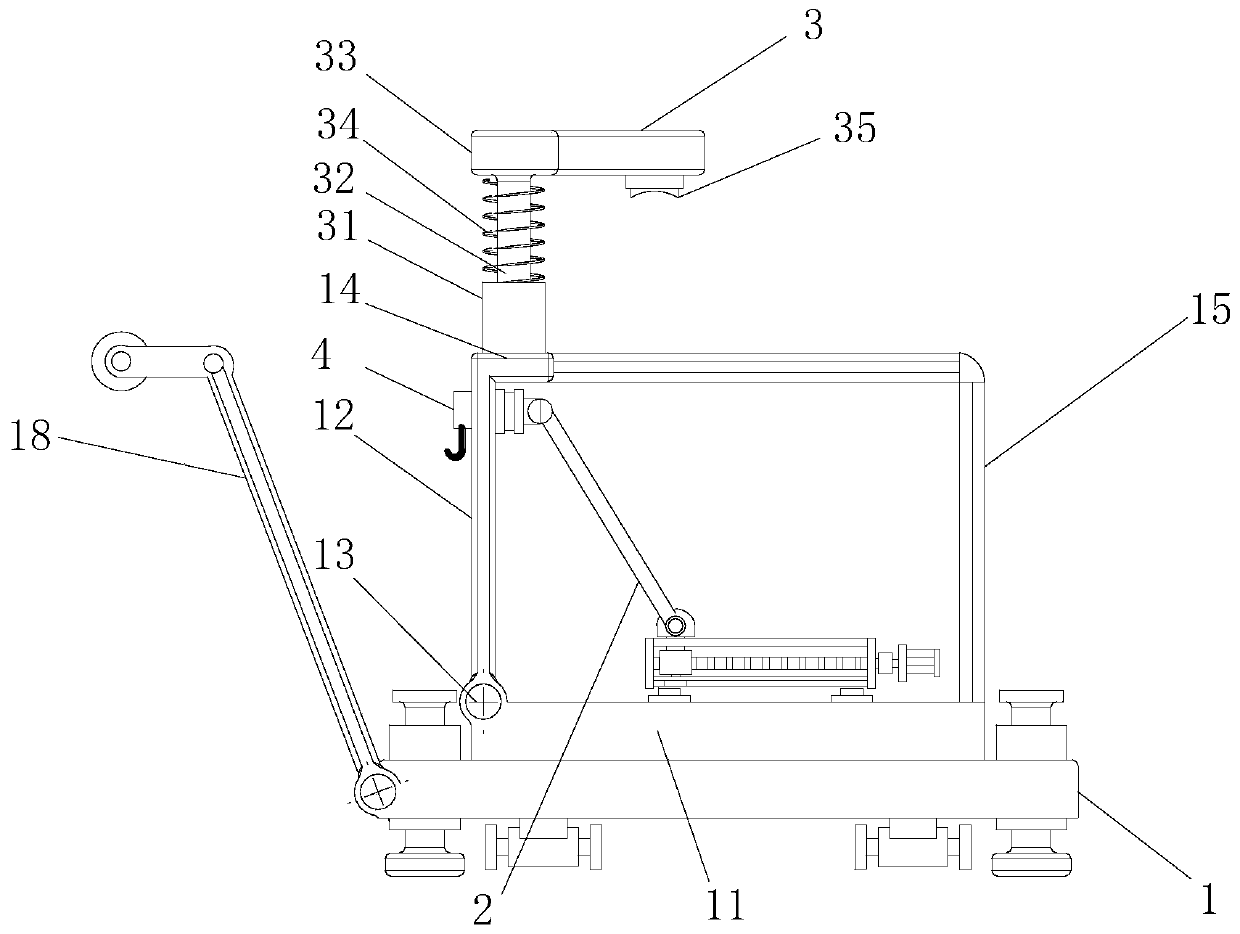

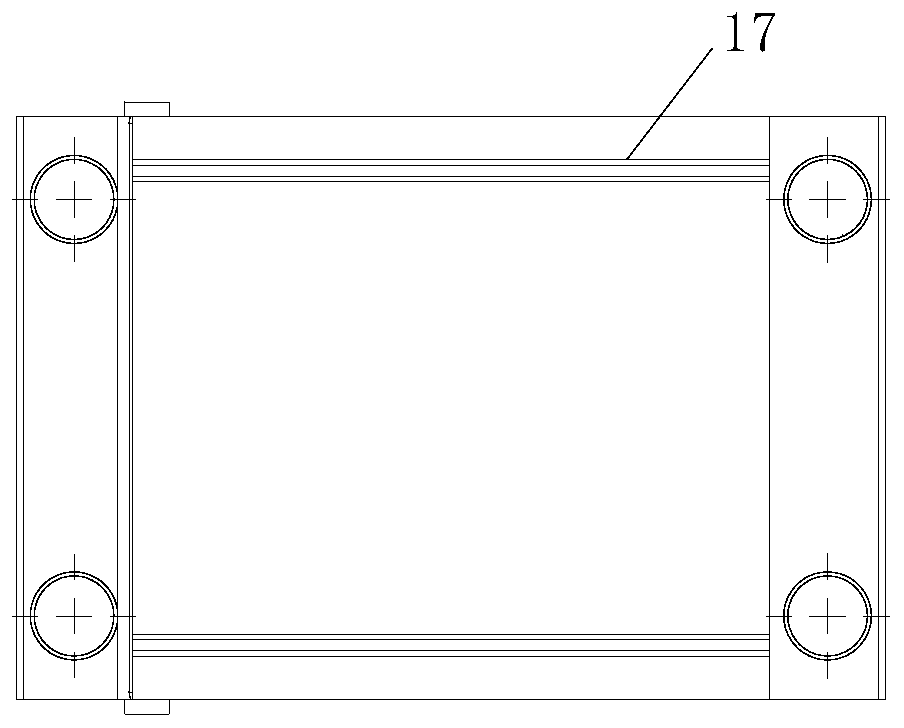

A physical education equipment transport device

InactiveCN110341774AReduce space consumptionAvoid rubbing against each otherSport apparatusHand carts with multiple axesPhysical educationEngineering

The invention relates to the technical field of physical education, and more specifically relates to a physical education equipment transport device comprising a pedestal. A base is mounted on the pedestal; a movable frame is mounted on the base; and the movable frame is movably mounted in sliding rails on an upper surface of the base through sliding blocks. One end of the base is mounted with a folding frame plate, and the folding frame plate is mounted on the base through a movable shaft. Side edges of the folding frame plate and the base are provided with an adjusting frame. The adjusting frame includes an adjusting frame, and the adjusting frame is mounted on one side edge of the base. The adjusting frame is internally provided with a driving screw, and the driving screw is provided with the driving sleeve. The driving sleeve is externally connected to a sliding block. The top of a side edge of the folding frame plate is provided with a connecting bolt, and the connecting bolt andthe sliding block are connected by a transmission link. The apparatus of the application adopts a combined installation design to reduce space occupation, is diversified in functions, and facilitatesfixing and transferring.

Owner:XUCHANG UNIV

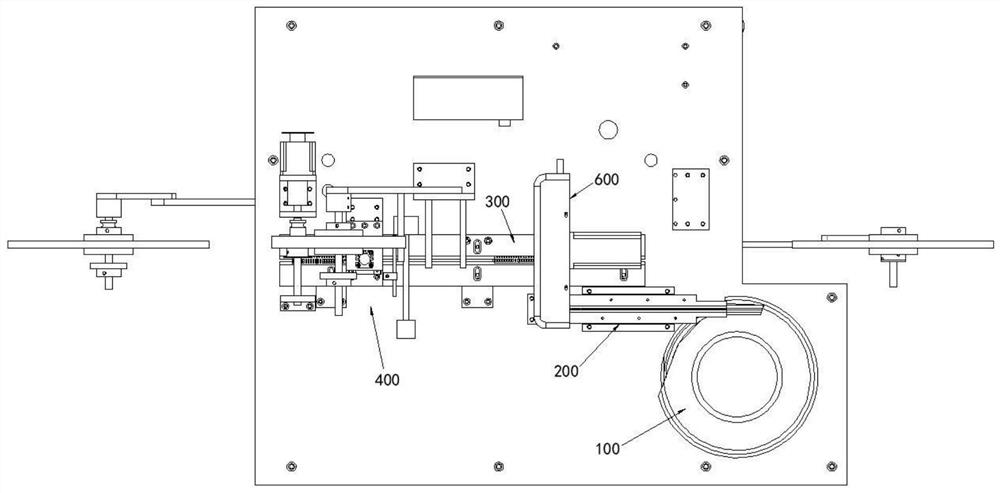

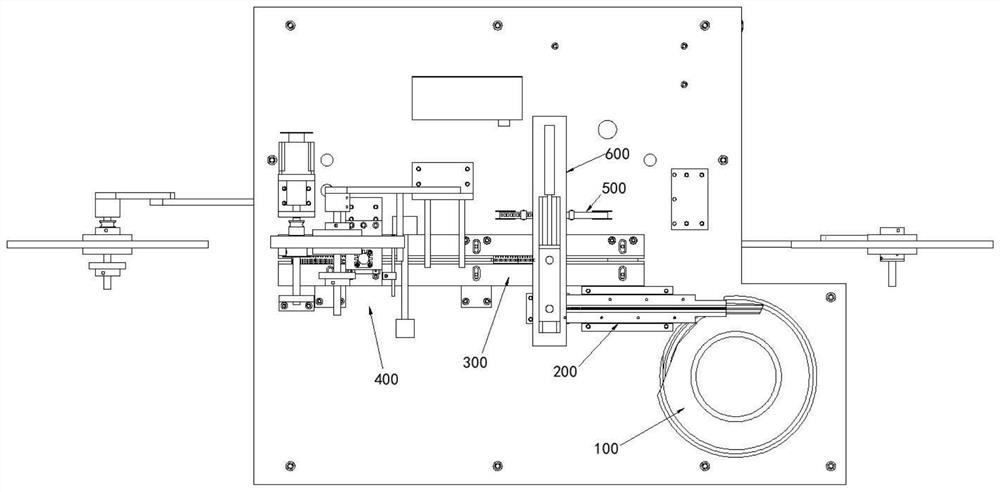

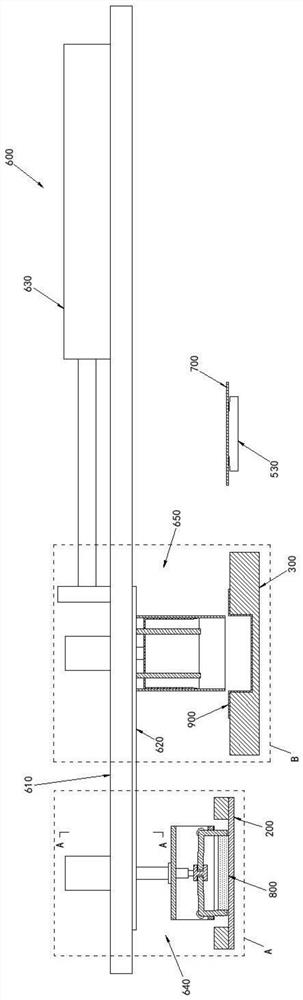

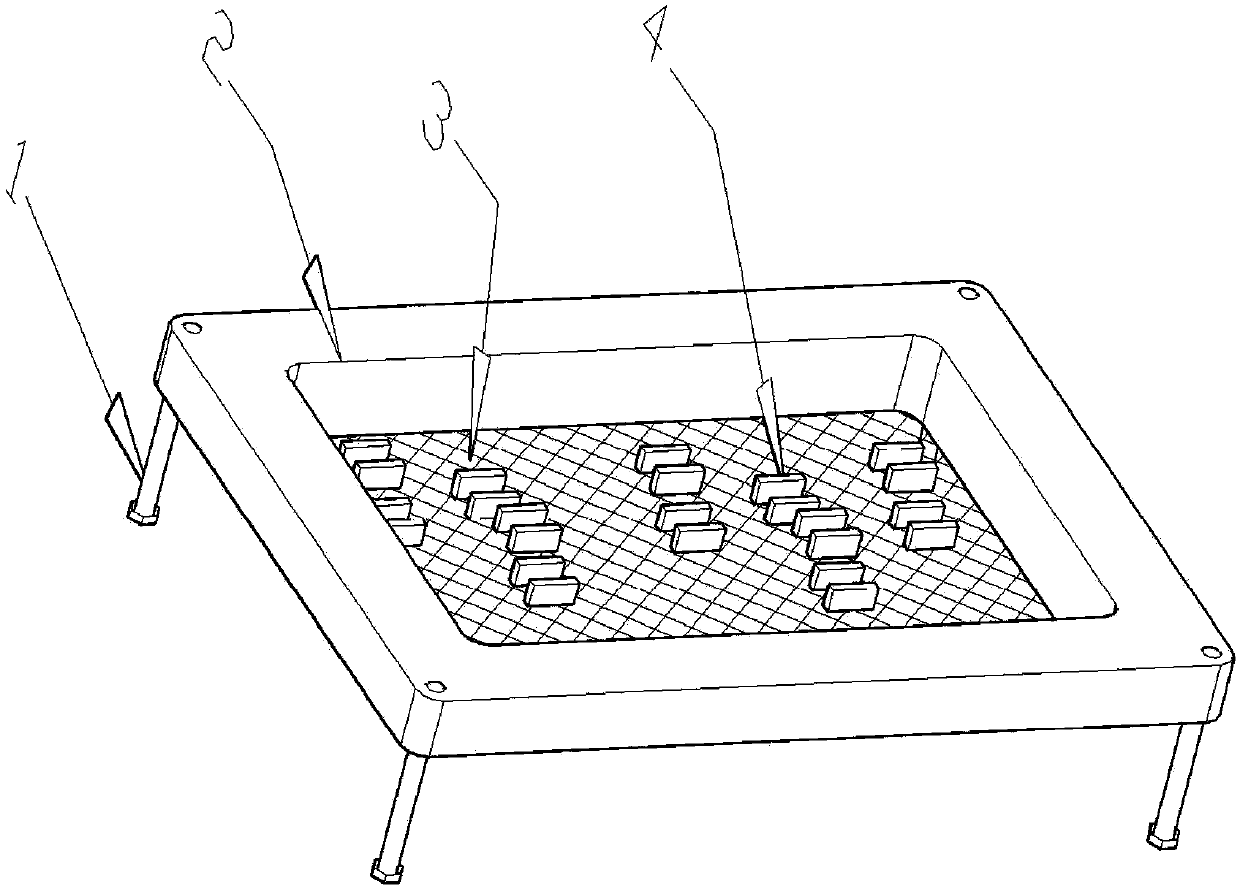

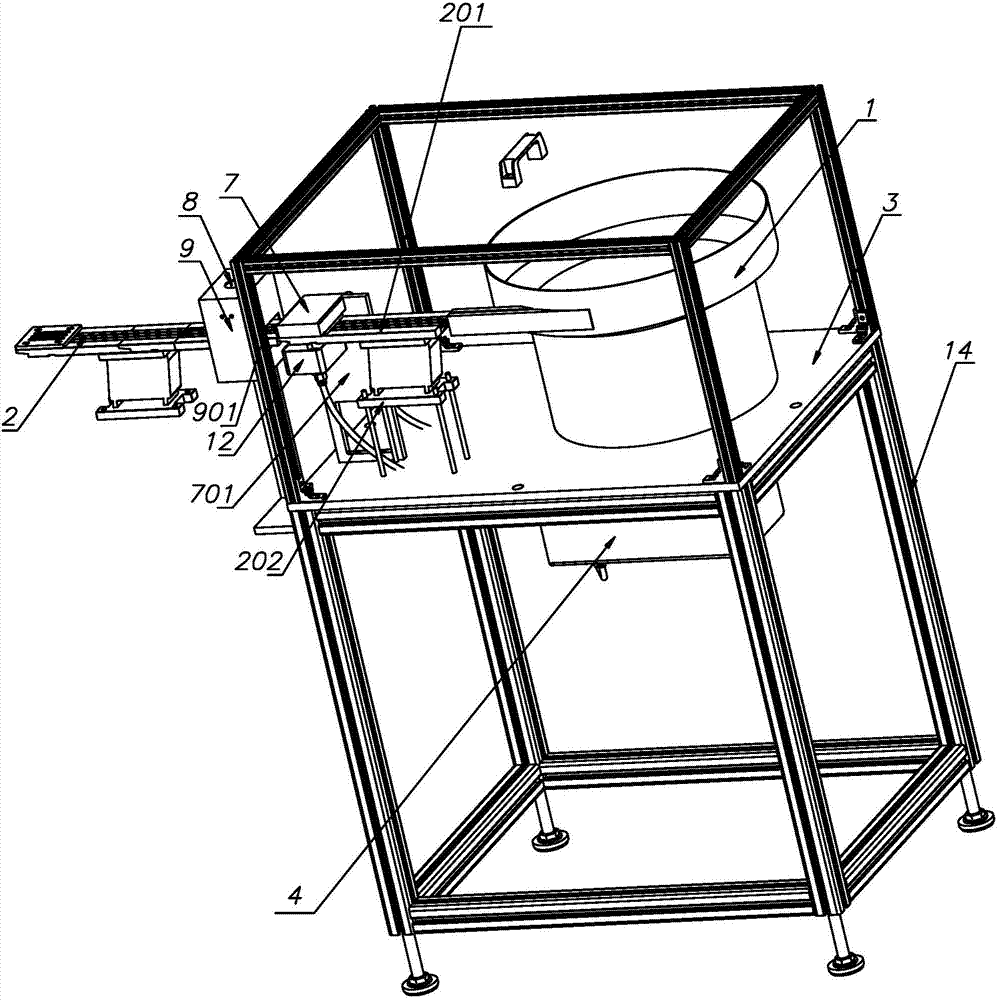

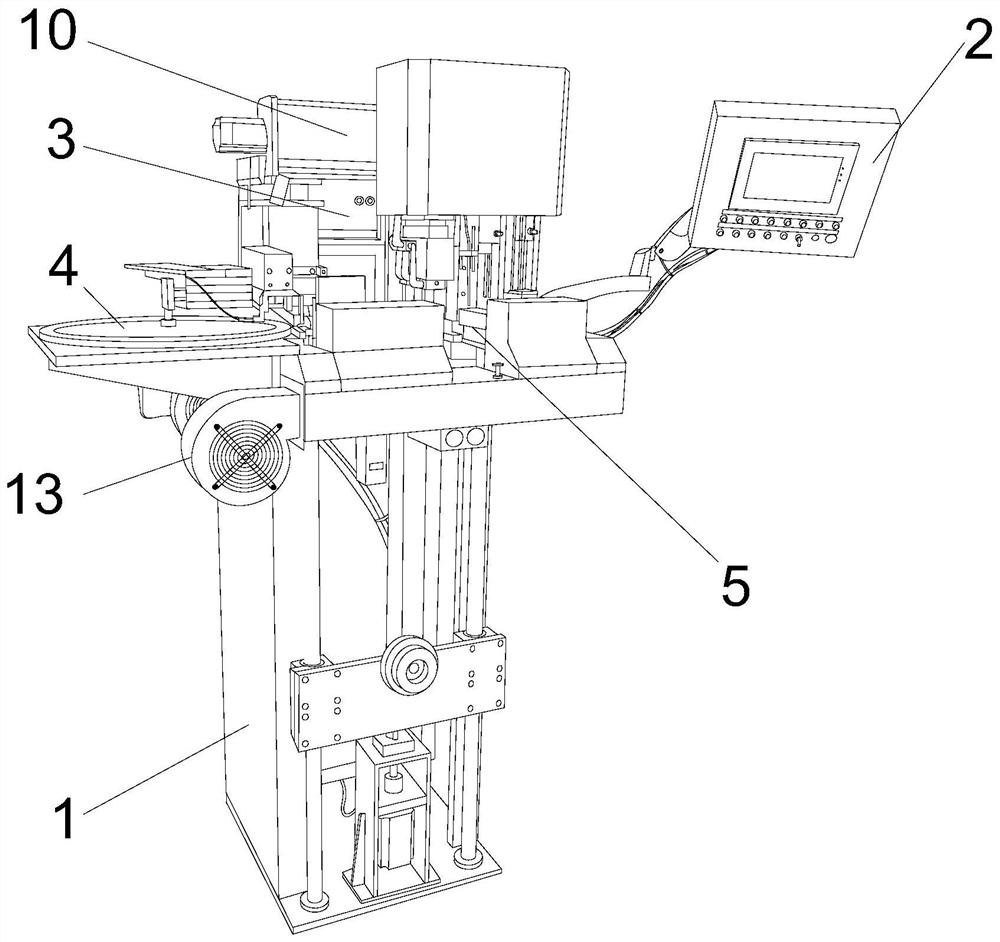

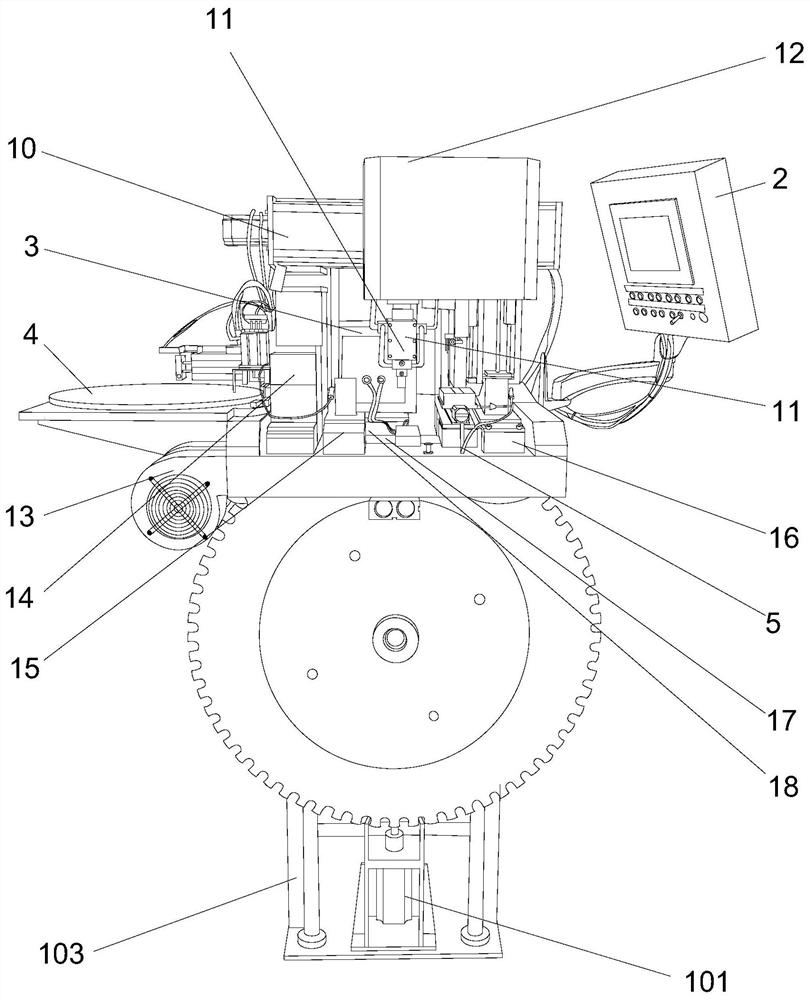

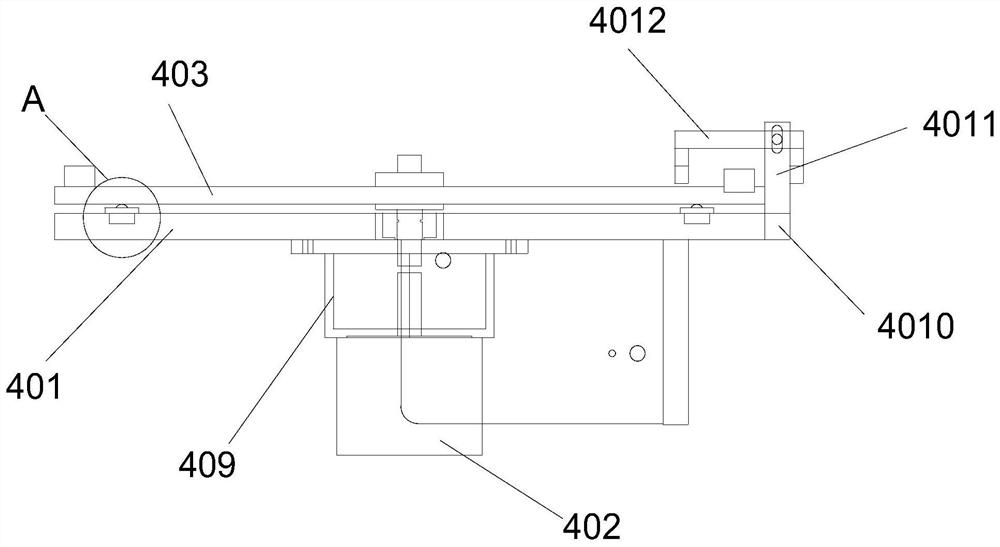

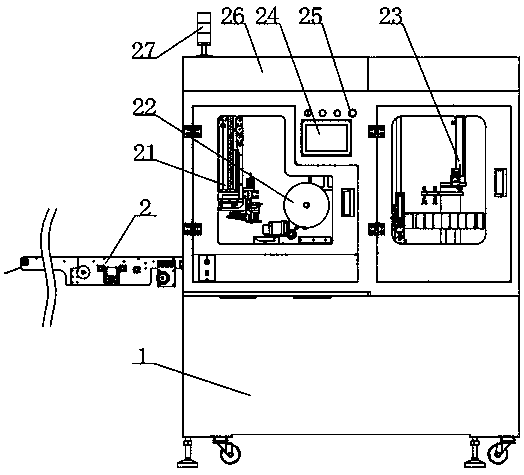

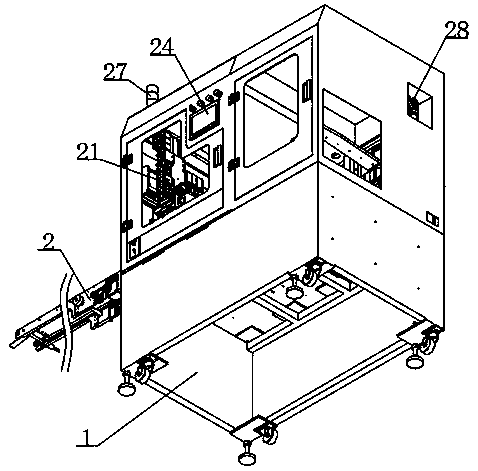

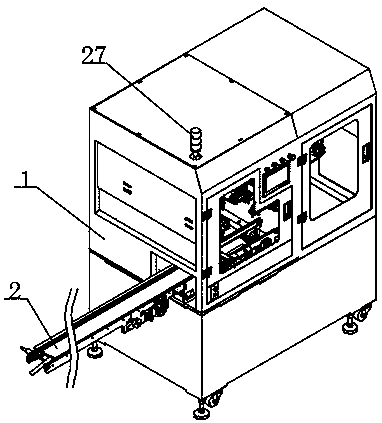

Packaging equipment for thick-film chip resistor

InactiveCN112435819AFast stepping speedAvoid rubbing against each otherEnvelope/housing resistor manufactureWaferingThin membrane

The invention discloses packaging equipment for a thick-film chip resistor. The packaging equipment comprises a vibrating disc, a resistor track, a carrier tape track, a packaging mechanism, a thin film conveying assembly and a manipulator, the vibrating disk is connected with a resistance track, the resistance track is parallel to the carrier tape track, and the packaging mechanism is installed on the carrier tape track; the thin film conveying assembly conveys a strip-shaped thin film to move forwards, and the strip-shaped thin film is parallel to the carrier tape track; the mechanical arm comprises a basic platform, a moving platform, a first air cylinder, a resistor grabbing assembly and a film grabbing assembly. The moving platform and the first air cylinder are both installed on thebasic platform, the first air cylinder drives the moving platform to horizontally move, and the moving direction of the moving platform is perpendicular to the carrier tape track. According to the packaging equipment for the thick-film chip resistors, the thin-film grabbing assembly is linked with the resistor grabbing assembly, the thin-film grabbing assembly can insert one thin-film piece between the two chip resistors in time, the two chip resistors in the same hole are separated by the thin-film piece, and mutual friction between the two chip resistors is avoided.

Owner:江西昶龙科技有限公司

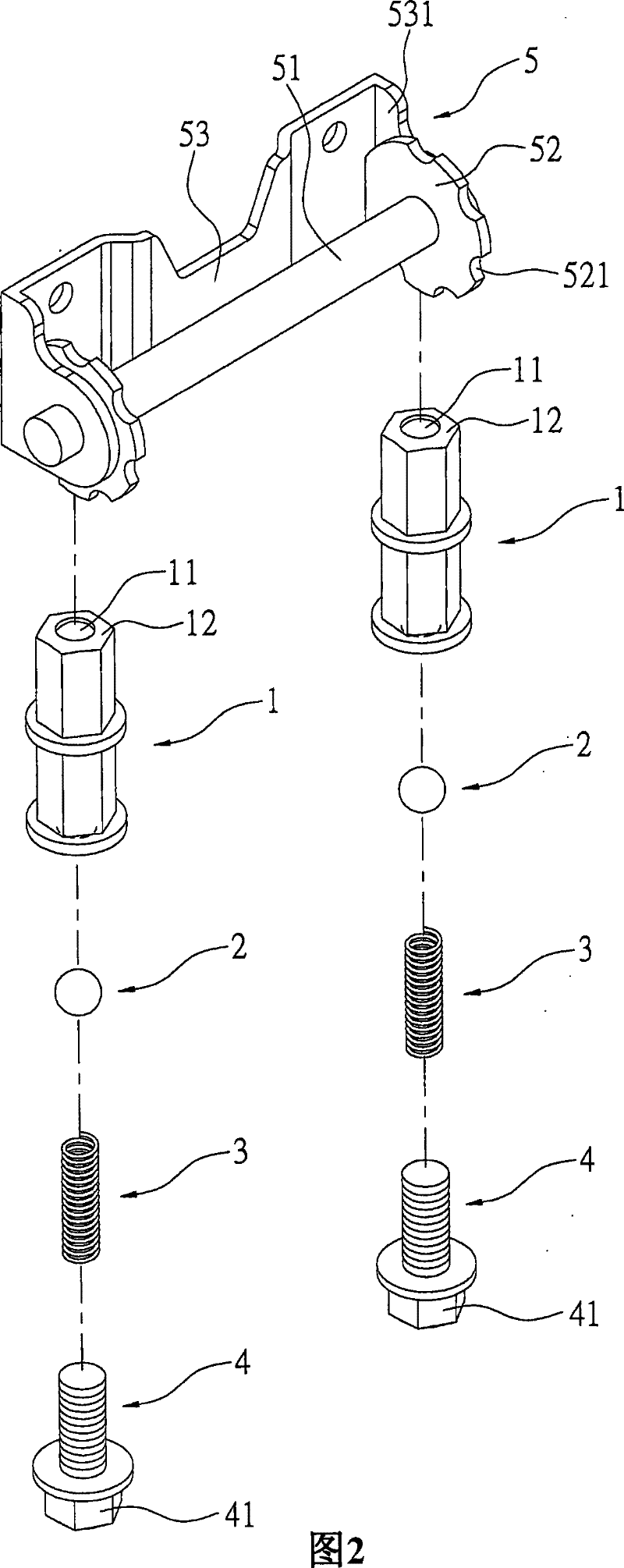

Cash transaction machine

ActiveCN101470917BAvoid rubbing against each otherPaper-money handling devicesCoin/currency accepting devicesEngineeringClutch

Provided is a cash transaction machine including a temporary stack portion. The cash transaction machine includes: a carriage receiving a paper medium stacked in the temporary stack portion; a driving belt transferring the carriage to a medium outlet; a pressing belt pressing the paper medium being transferred by the carriage in interoperation with the driving belt; a plurality of guide rollers being provided along a travel path of the carriage to define a travel path of the driving belt and a travel path of the pressing belt; and a one-way clutch adjusting an interoperating state between thedriving belt and the pressing belt to prevent a friction from occurring between the pressing belt and the paper medium while the paper medium is being loaded to the carriage.

Owner:NAUTILUS HYOSUNG

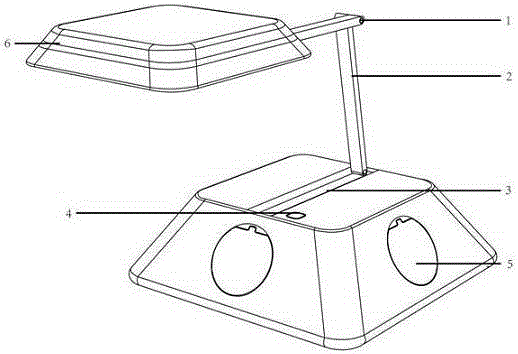

Multifunctional socket with table lamp function

InactiveCN105186228AAvoid enteringAvoid rubbing against each otherCoupling device detailsSkyEngineering

A multifunctional socket with a table lamp function of the present invention relates to the integration of the multifunctional socket and the table lamp. The multifunctional socket with the table lamp function comprises a three-hole socket, a two-hole socket and a USB socket, and the top of the multifunctional socket is equipped with the table lamp. At present, the USB jacks on the sockets are the essential parts, but people are always afraid of the danger to touch the sockets when the hands are wet, because the sockets face the sky, the water on the hands is easy to drop into the sockets, and each jack is bare outwards. By the design of the present invention, the sockets are arranged at the surrounding of the multifunctional socket aslant and are covered by the covers, thereby reducing the dangers substantially.

Owner:NANJING BIRCHEN INDAL DESIGN

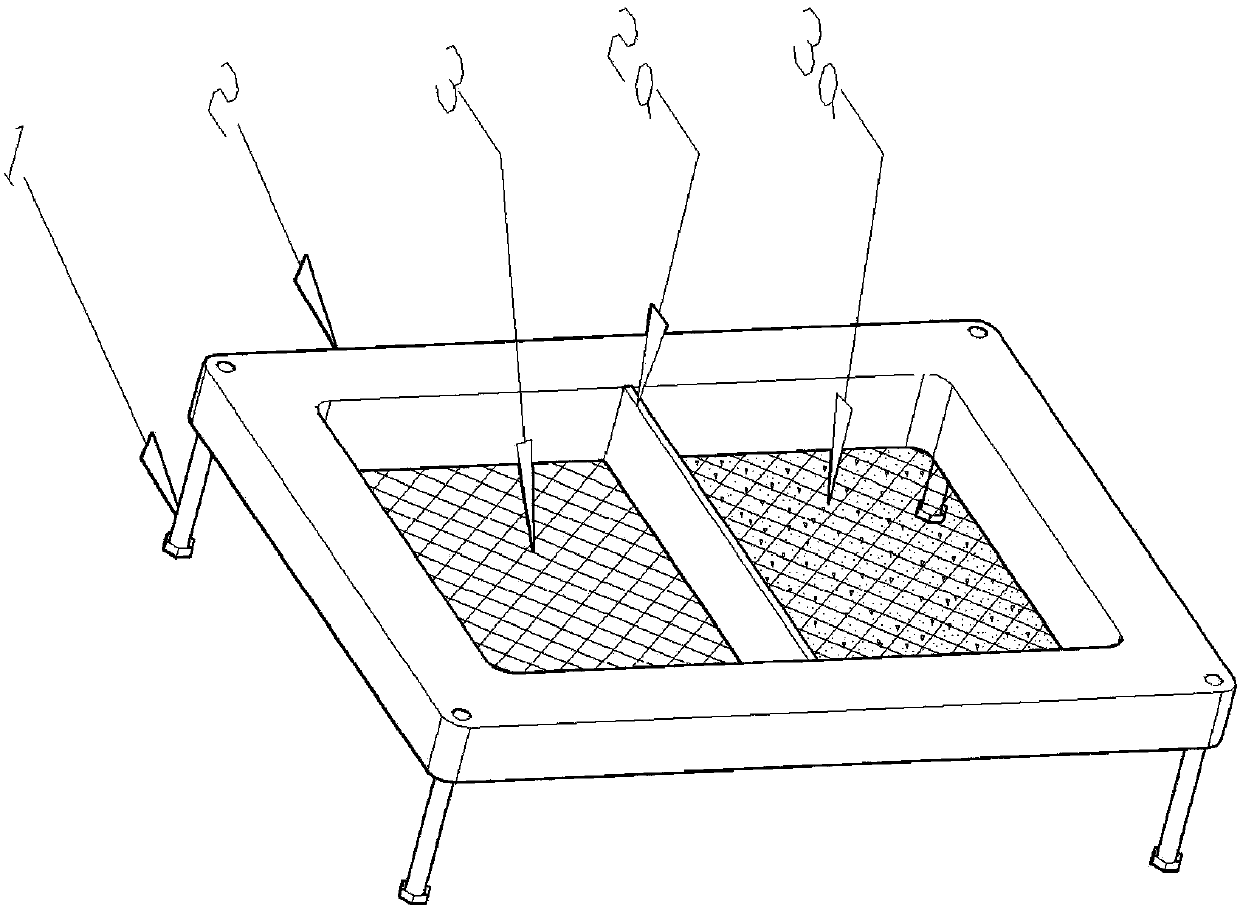

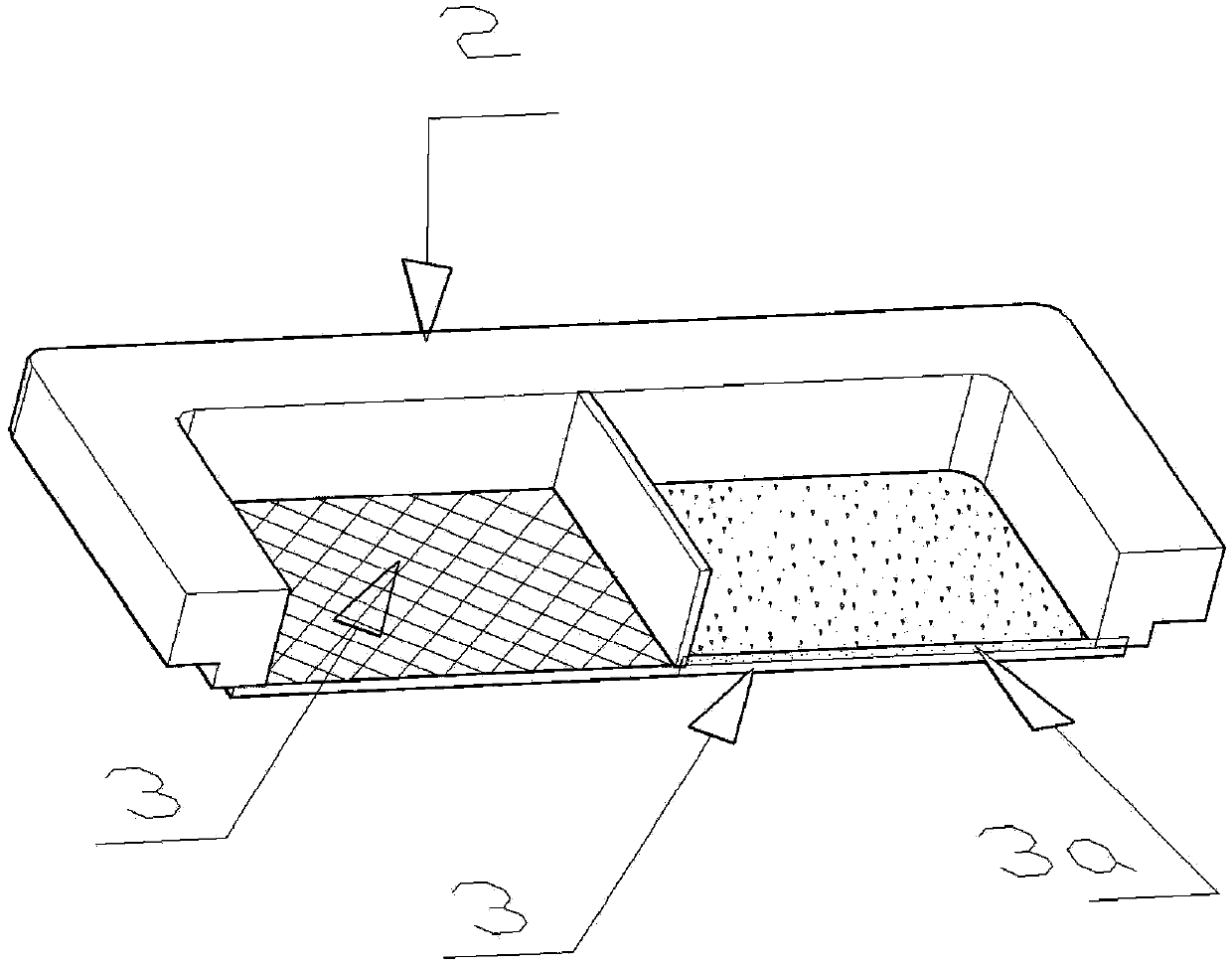

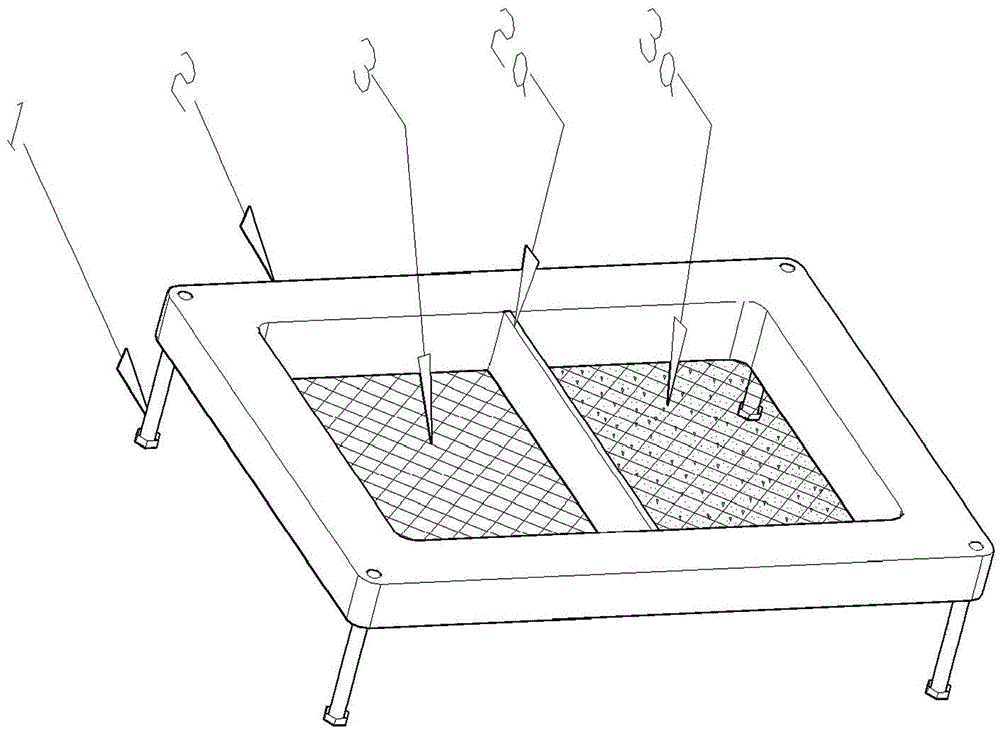

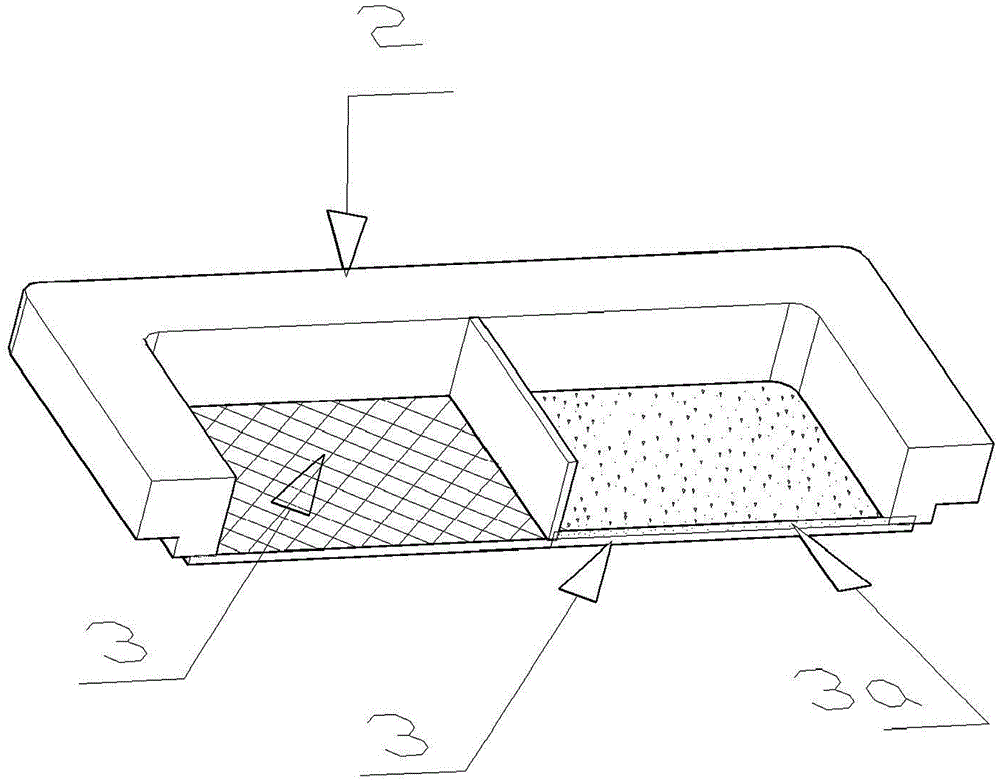

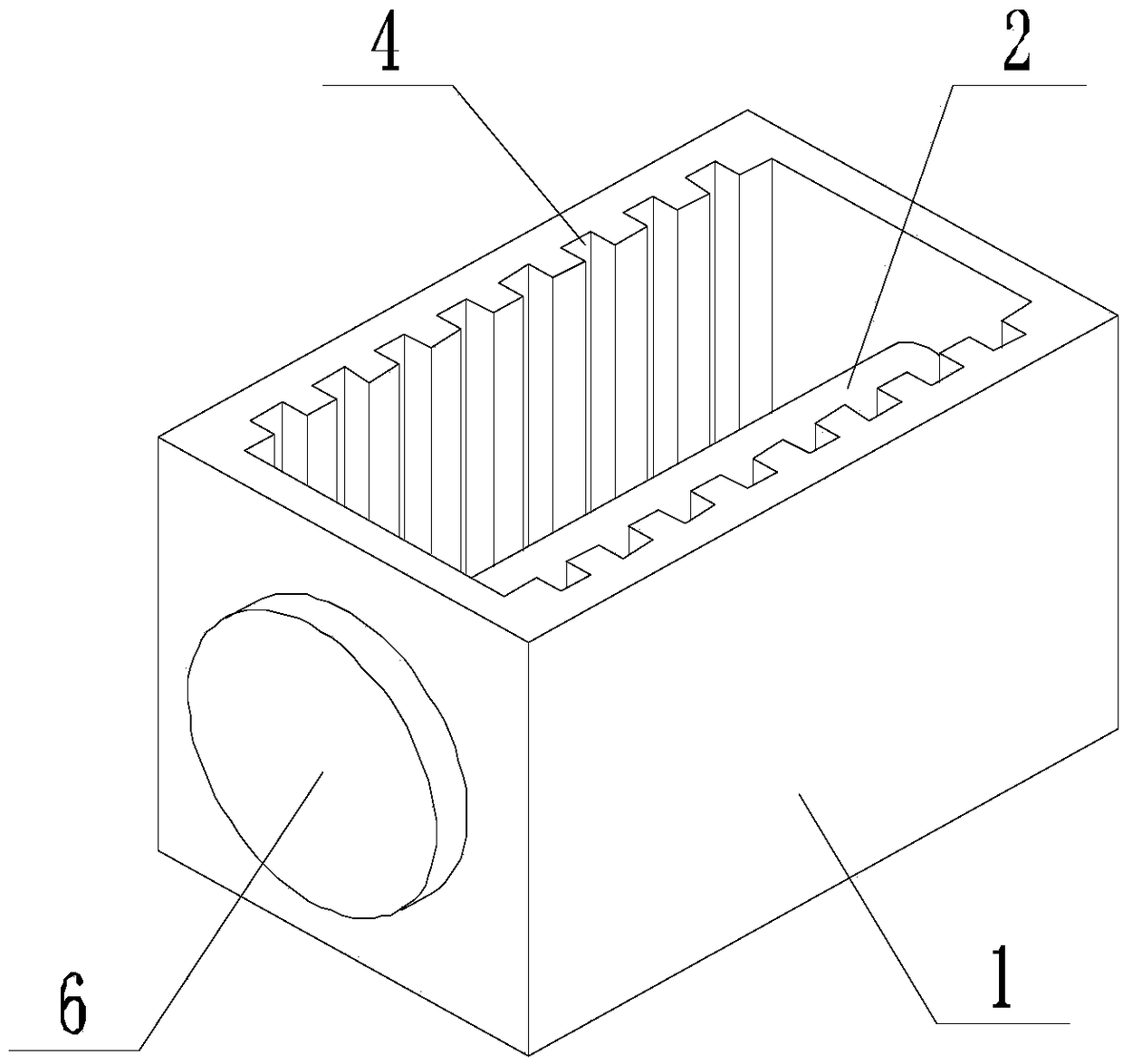

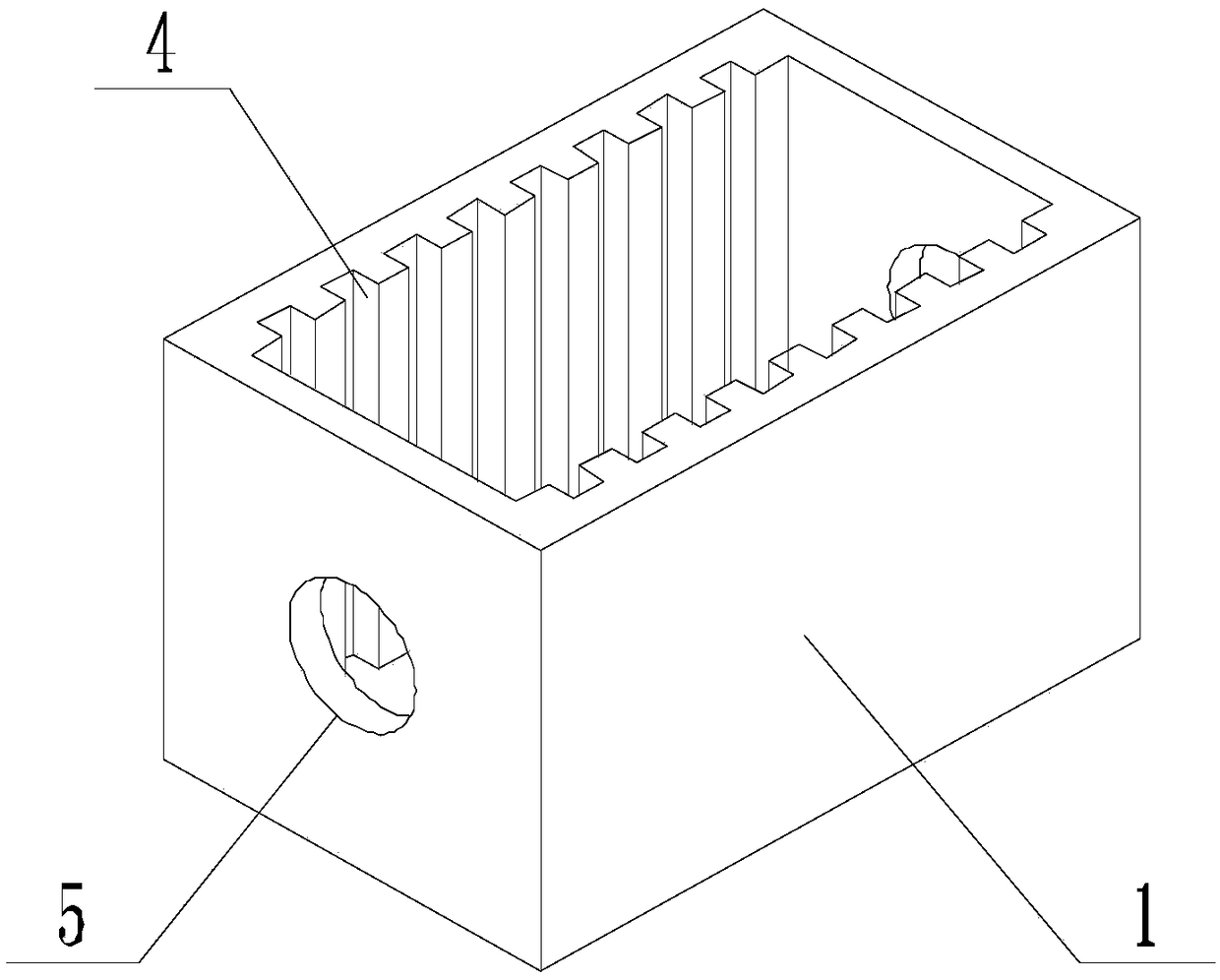

Plasma cleaning auxiliary device for components and parts

ActiveCN103433261AAvoid accumulationAvoid rubbing against each otherCleaning processes and apparatusUltraviolet lightsEngineering

The invention relates to a plasma cleaning auxiliary device for components and parts. The bottom of a frame (2) is connected with a screen mesh (3) to serve as the bottom of a tray, a partition plate (4) is arranged in the middle of the frame (2) to divide the tray into two areas, and 704 or 705 silica gel (3a) is coated on the screen mesh (3) in one area. When the plasma cleaning auxiliary device is used, an element (4) cleaned in a double-side mode is arranged on the screen mesh (3) on the left area, an element (5) cleaned in a single-side mode is arranged on the silica gel (3a) on the right area, and finally a cleaning device is arranged into a plasma cleaning machine to be cleaned. The plasma cleaning auxiliary device has the advantages that by means of the action of leakage holes of the screen mesh, plasma can bombard the elements from all sides, and the cleaning efficiency is remarkably improved. The screen mesh can dredge and disperse airflow to prevent the elements from being blown by the airflow, piled and rubbed. The silica gel can absorb the components and the parts to prevent the components and the parts from being blown by the airflow, piled and rubbed. Compared with a method using a blue film or a UV film to fix the elements, the plasma cleaning auxiliary device removes a special film shifting machine and a special ultraviolet light machine and saves cleaning cost.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

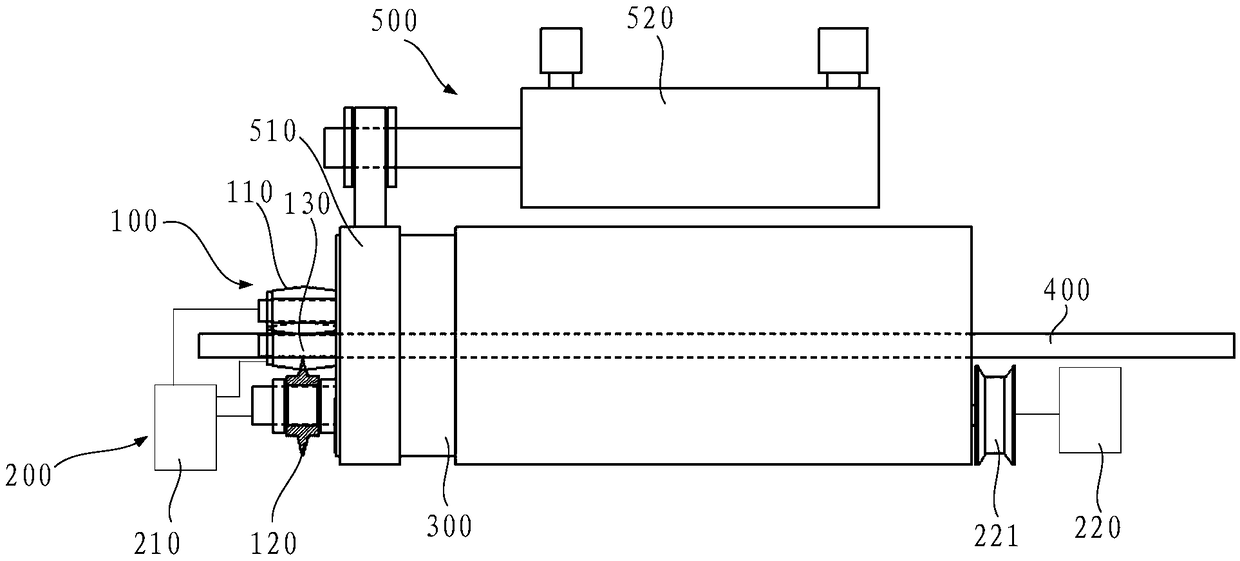

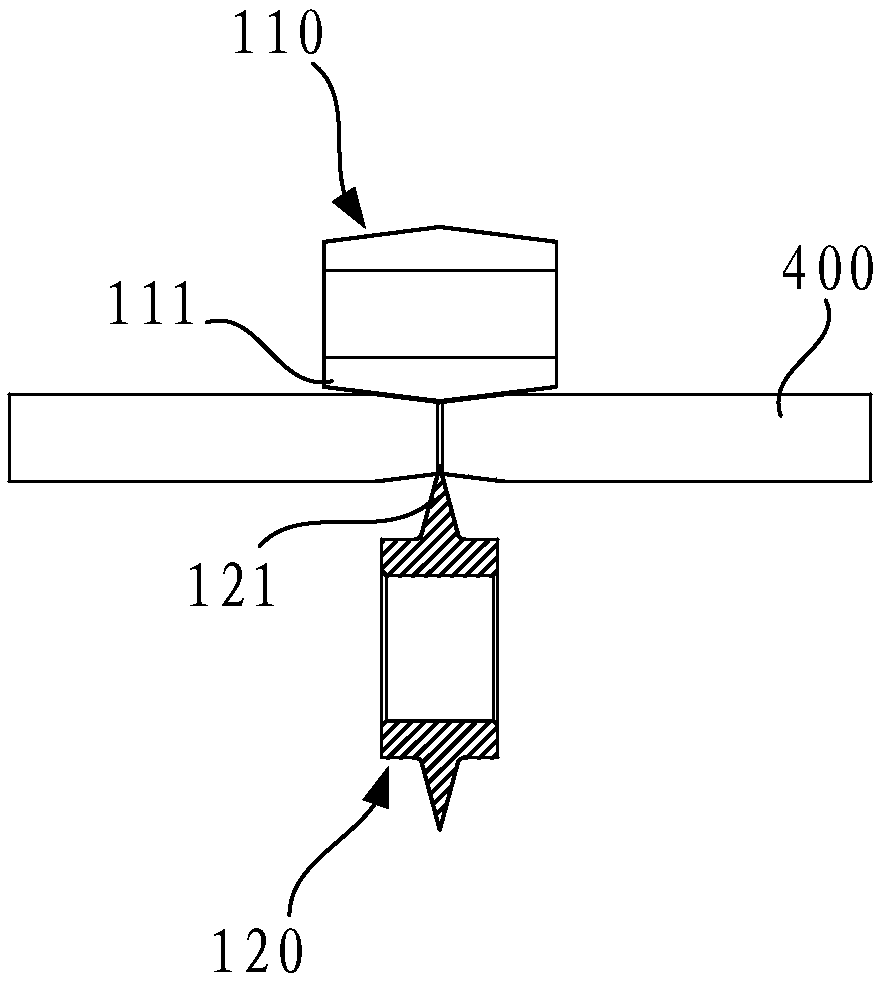

Copper tube cutting device

InactiveCN108890018AAvoid unstable cutting positionsAvoid rubbing against each otherWork clamping meansTube shearing machinesScrapAluminium

The invention relates to the technical field of cutting and processing, and discloses a copper tube cutting device. The copper tube cutting device includes a rack, and a knife head mechanism and a driving mechanism mounted on the rack, wherein the knife head mechanism comprises a cutting knife and a cutting table, and the head chamfer of the cutting knife is 25 degrees-40 degrees, the cutting table is opposite to the cutting knife, and the opposite end face of the cutter head is conic, the driving mechanism is rotatably connected with the knife head mechanism, and can drive the knife head mechanism to move along the direction perpendicular to the copper tube to be cut, and drive the knife head mechanism to rotate when the knife head mechanism is clamped tightly to the copper tube to be cut, and the knife head mechanism is clamped to the copper pipe to be cut while cutting, and the unstable cutting position is avoided, the driving mechanism drives the knife head mechanism to move, and simultaneously drives the knife head mechanism to rotate, the cutting knife and the cutting table squeeze the copper tube, the pipe mouth is internal contraction, while the pipe wall of the copper tubeis extruded into an inward tilt cone, so that the tube will not touch the finned tube when wearing the tube, thereby solving the problem of scraping aluminium scraps and aluminum powder at the mouthof long U copper pipe.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

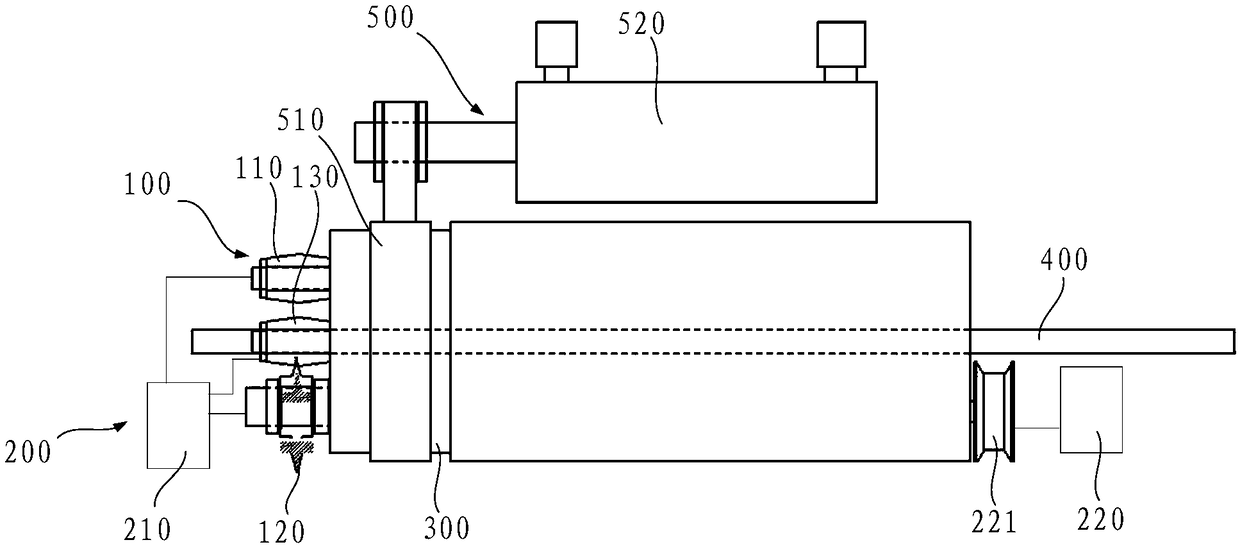

Module for adding protective agents to contacts and automatic assembly machine and assembly method for contacts

ActiveCN104733199AImprove work efficiencyHigh degree of automationCharge manipulationElectric switchesAssembly machineProtective Agents

The invention discloses a module for adding protective agents to contacts and an automatic assembly machine and assembly method for the contacts. The module for adding the protective agents to the contacts comprises a contact arrangement machine and a touch feeding machine, wherein one end of the touch feeding machine is connected with the touch arrangement machine, and the other end of the touch feeding machine can be connected with a contact assembly station; a protective agent pouring device used for adding the protective agents to the contacts and a drying device used for drying the contacts to which the protective agents are added are arranged at corresponding positions of a conveying belt of the contact feeding machine. The automatic assembly machine for the contacts comprises the contact assembly station and the module for adding the protective agents to the contacts, wherein the module for adding the protective agents to the contacts is connected with the contact assembly station which is provided with an assembly machine structure. The assembly method for the contacts includes the steps that the contacts to be assembled are sequentially arranged in the state that the contacts can be conveniently assembled, the contacts are conveyed to the assembly station through a conveying device, the protective agents are painted on the contacts in the conveying process, and then the contacts are assembled to a contact support. According to the module for adding the protective agents to the contacts and the automatic assembly machine and assembly method for the contacts, the protective agents are added to the contacts in the conveying process after the contacts are arranged and before the contacts are assembled, and mutual friction between the contacts is avoided after the protective agents are added to the contacts.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

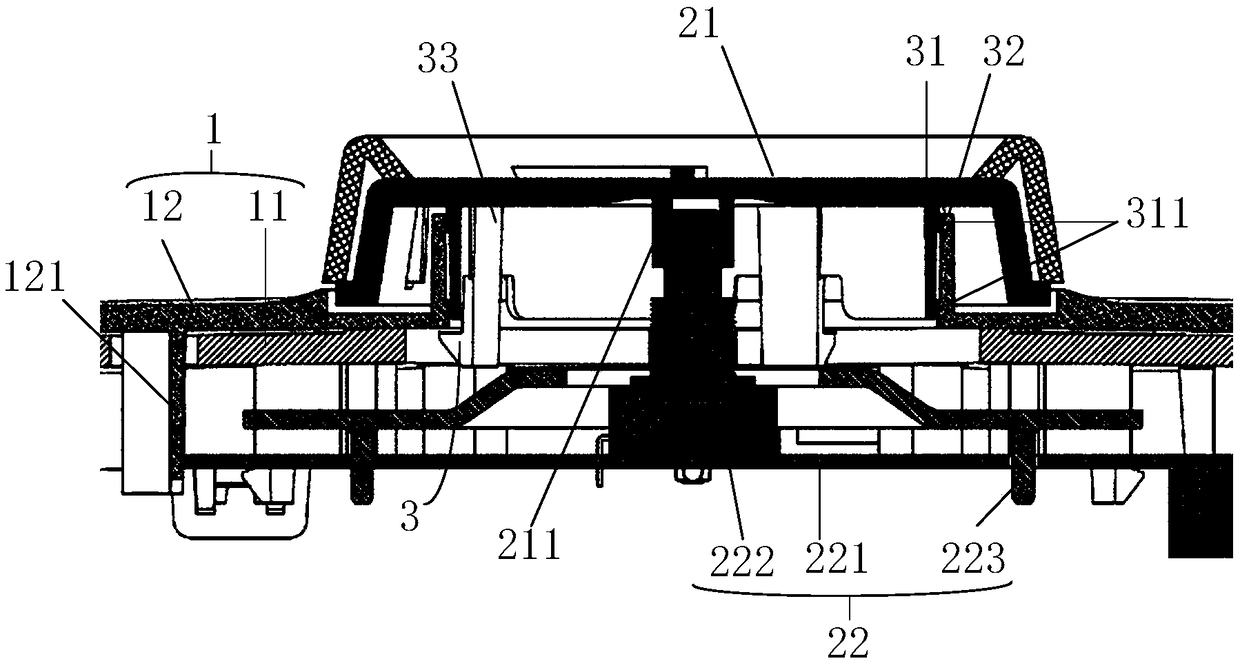

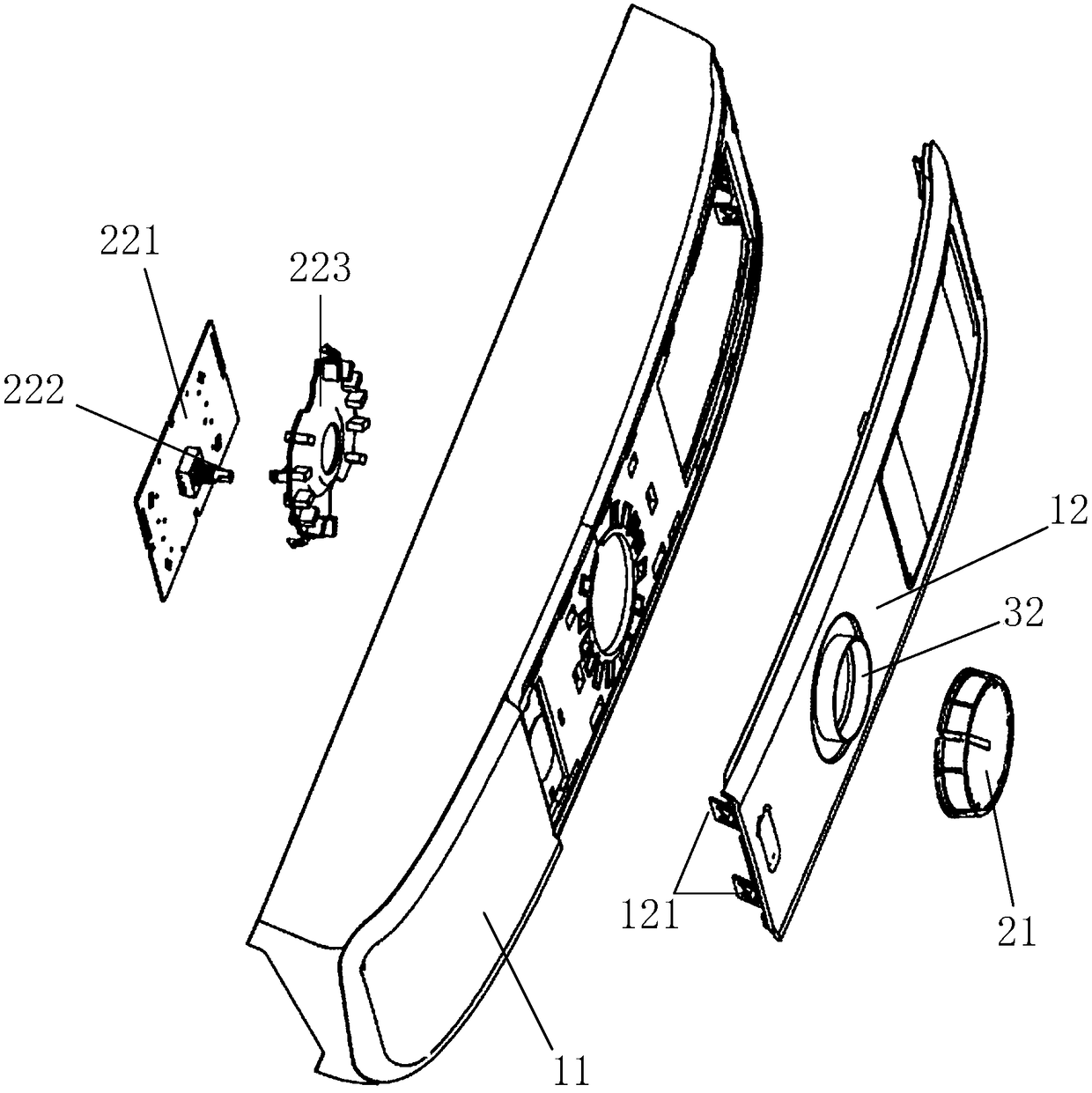

Control panel assembly of household appliance

PendingCN109375702AEasy to fixReduce connectivityControlling membersEngineeringMechanical engineering

The invention, which belongs to the technical field of household appliances, in particular relates to a control panel assembly of a household appliance so that a problem that the rotary knob can not be installed reliably based on the rotary knob mounting mode of the existing household appliance can be solved. The control panel assembly comprises a control panel, a rotary knob assembly, and a limitassembly. The rotary knob assembly is installed at the control panel in a rotatable manner. The limit assembly includes a first abutting member, a clamp member, and a second abutting member, whereinthe first abutting member and the clamp member are arranged at the rotary knob assembly and the second abutting member is arranged on the control panel; the first abutting member and the second abutting member are abutted cooperatively to limit the radial movement of the rotary knob assembly; and the clamp member and the control panel are in a clamping fit relationship to limit the axial movementof the rotary knob assembly. Therefore, the rotary knob assembly cooperates with the control panel by the limit assembly, so that inclination and dislocation of the rotary knob assembly relative to the rotary knob mounting position of the control panel are avoided. And thus the smoothness of the rotation of the rotary knob assembly is ensured and the installation reliability of the rotary knob assembly is enhanced.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

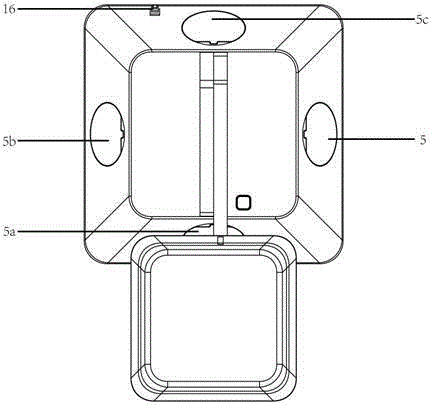

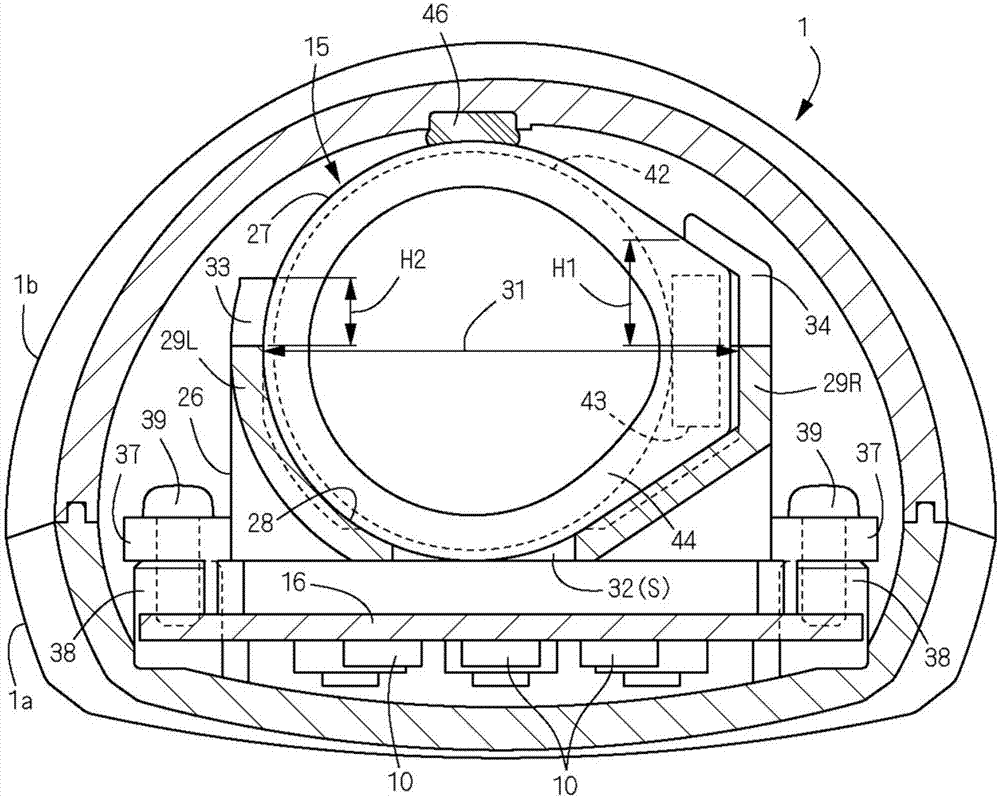

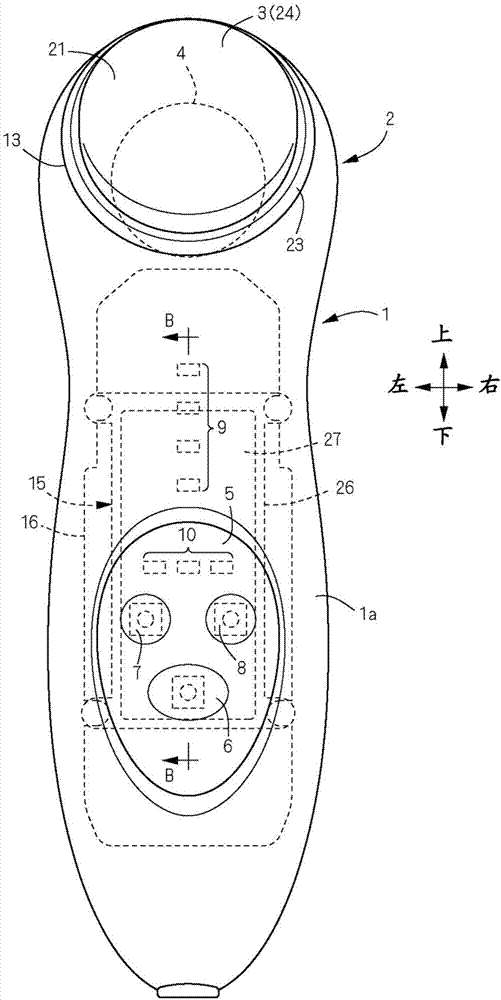

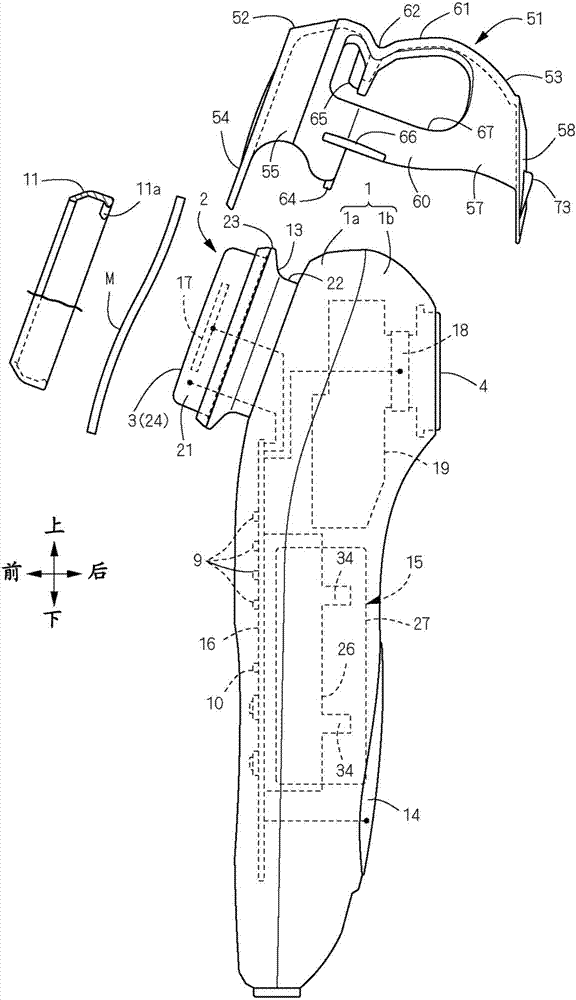

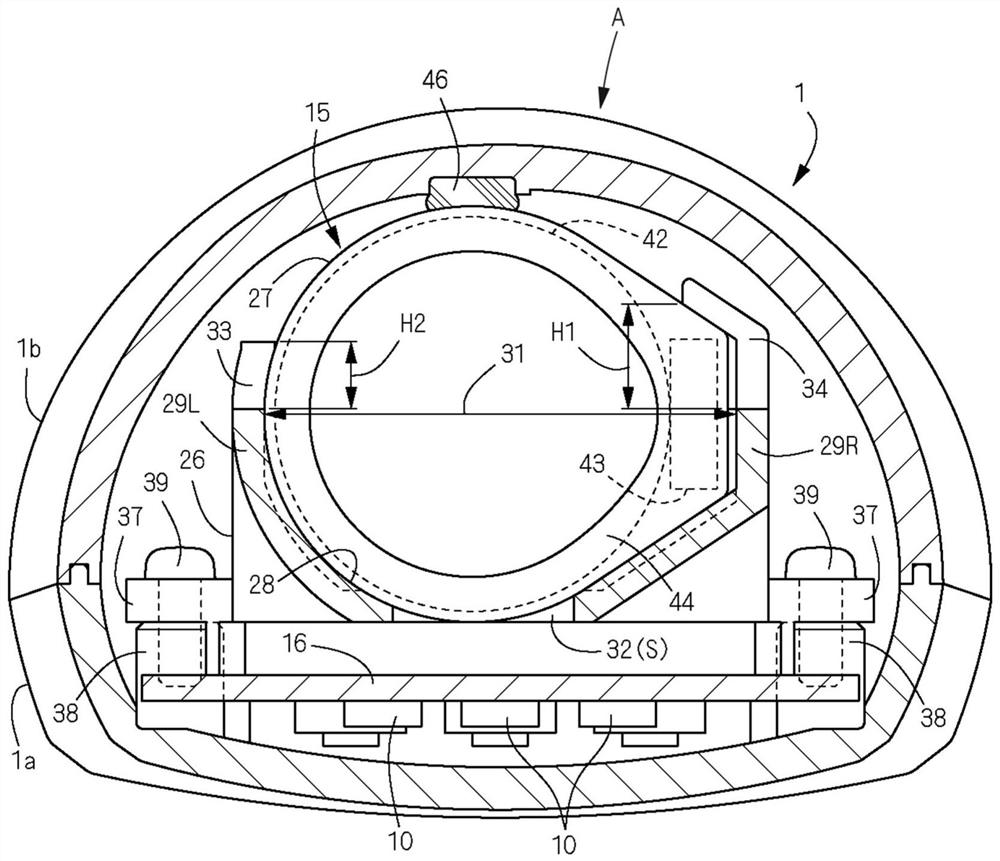

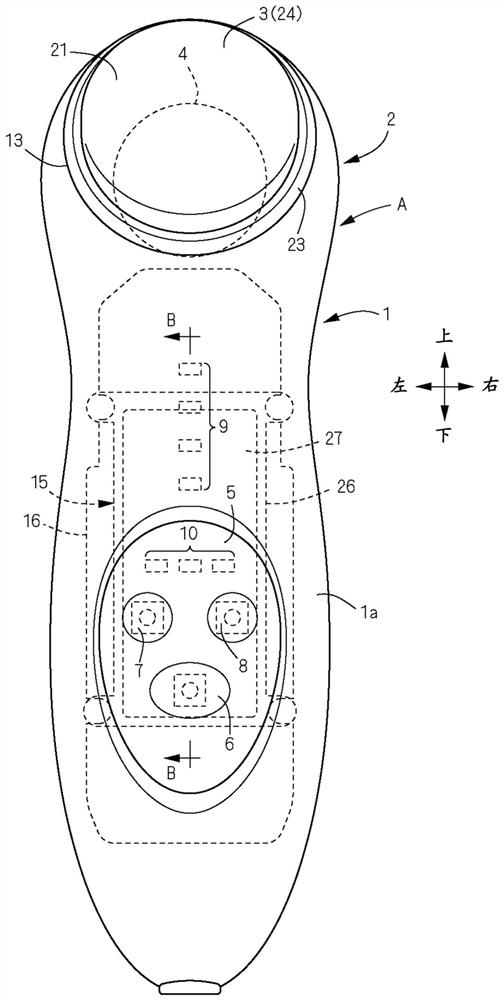

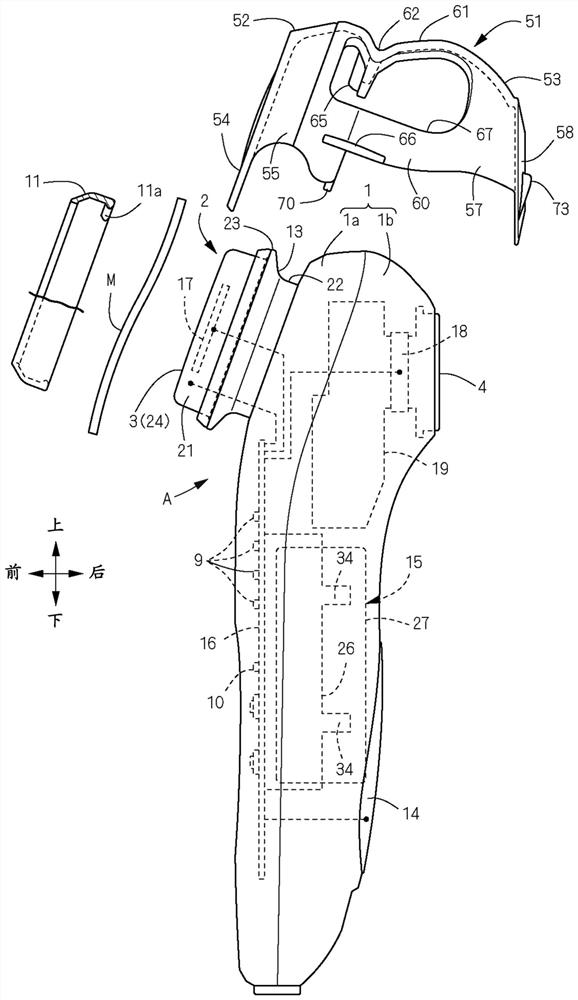

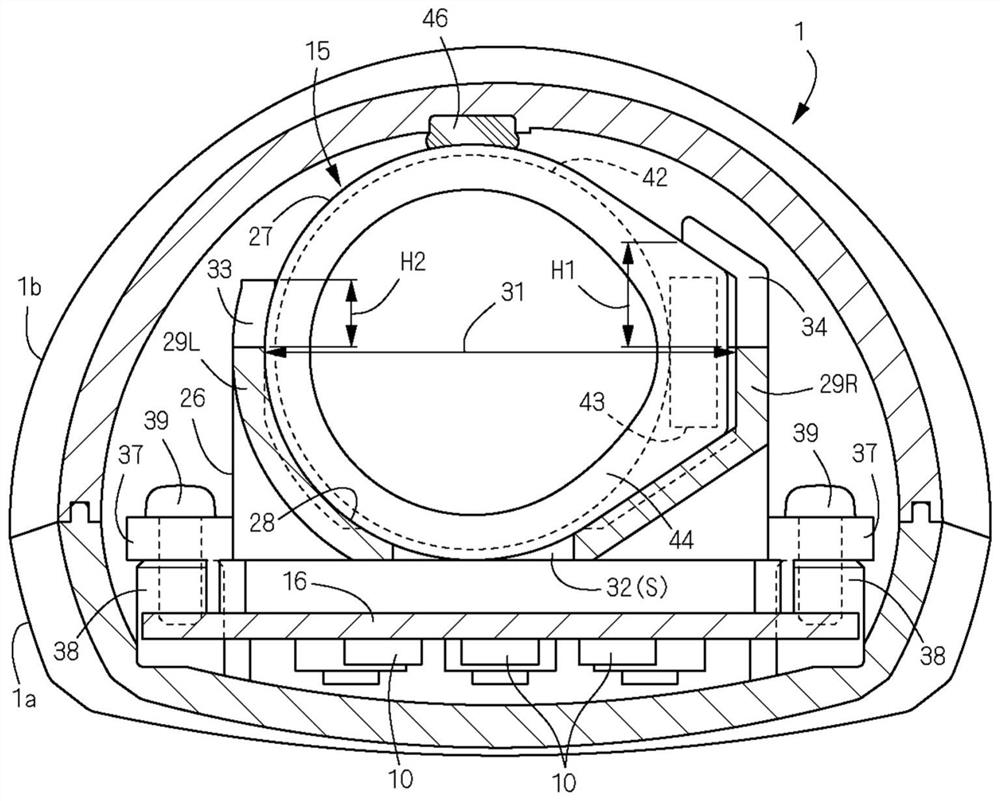

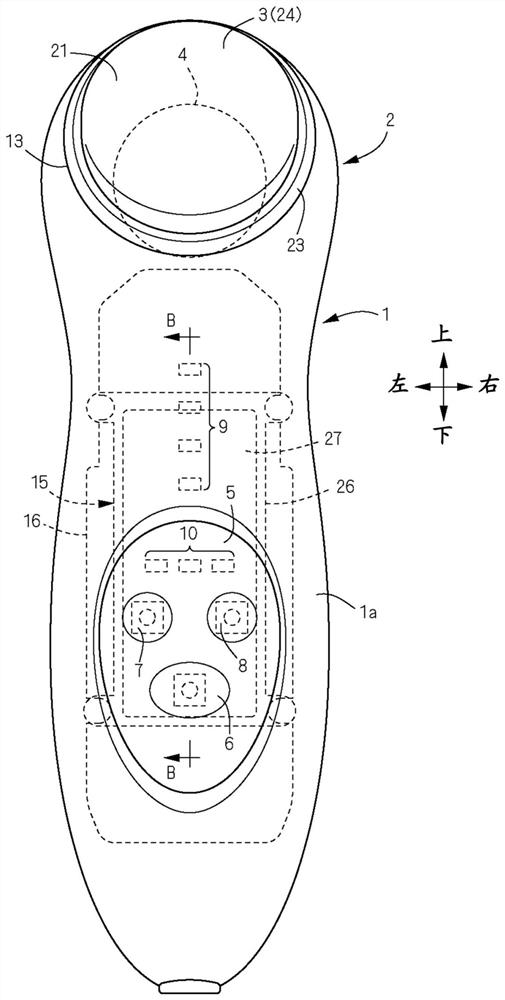

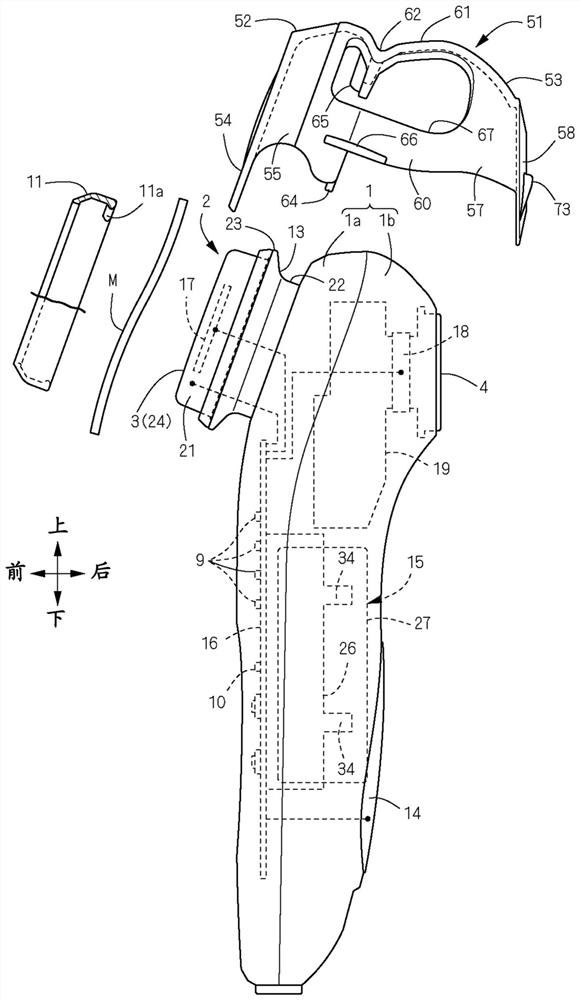

A small electric appliance and a cosmetics instrument

ActiveCN106920908ALimit unpluggingImprove structural strengthElectrotherapyCell component detailsElectrical devicesMiniaturization

Owner:MAXELL HLDG LTD

beauty appliance

The present invention provides a cosmetic device which can prevent loss of a cap and is excellent in usability. A protective cover (51) is detachably attached to the main body (A) having the skin electrode (24). A cover (11) for attaching a sheet-shaped absorbent liquid (M) to the skin electrode (24) is detachably attached to the skin electrode (24). The protective cover (51) can be attached to and detached from the main body (A) in a state where the cover (11) is attached to the skin electrode (24).

Owner:MAXELL HLDG LTD

Small electrical equipment and beauty appliances

ActiveCN106920908BLimit unpluggingImprove structural strengthElectrotherapyCell lids/coversElectrical batteryMiniaturization

Owner:MAXELL HLDG LTD

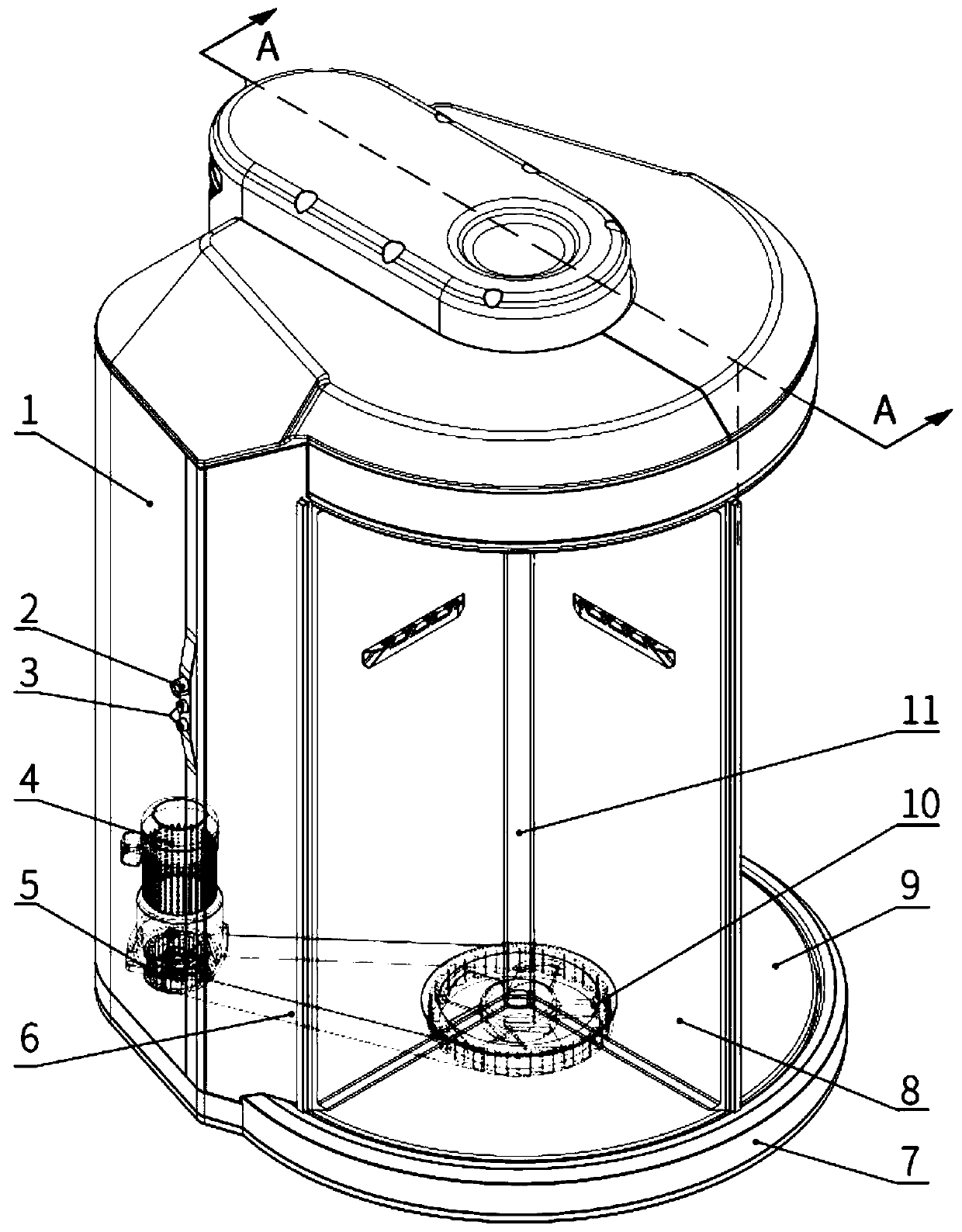

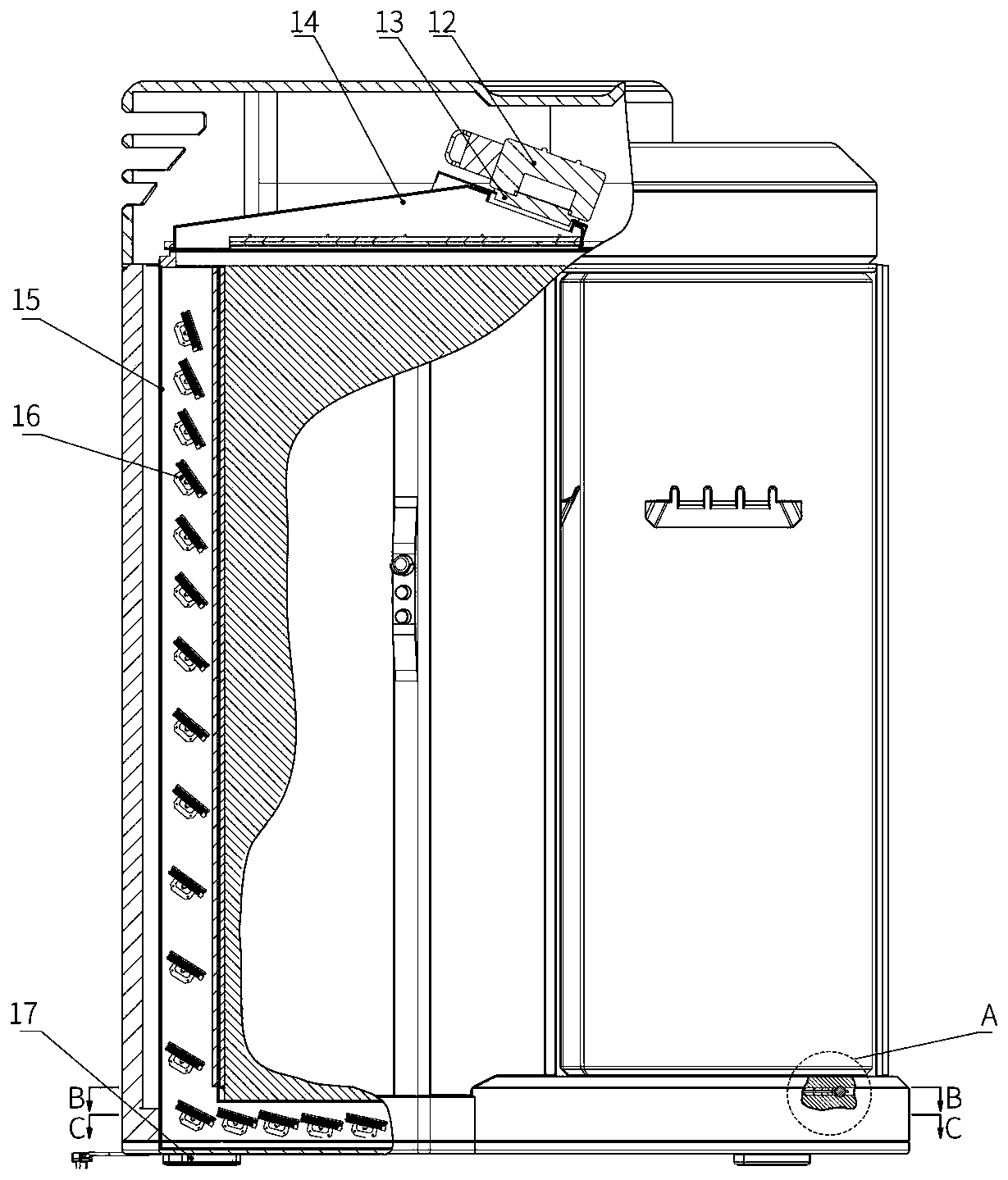

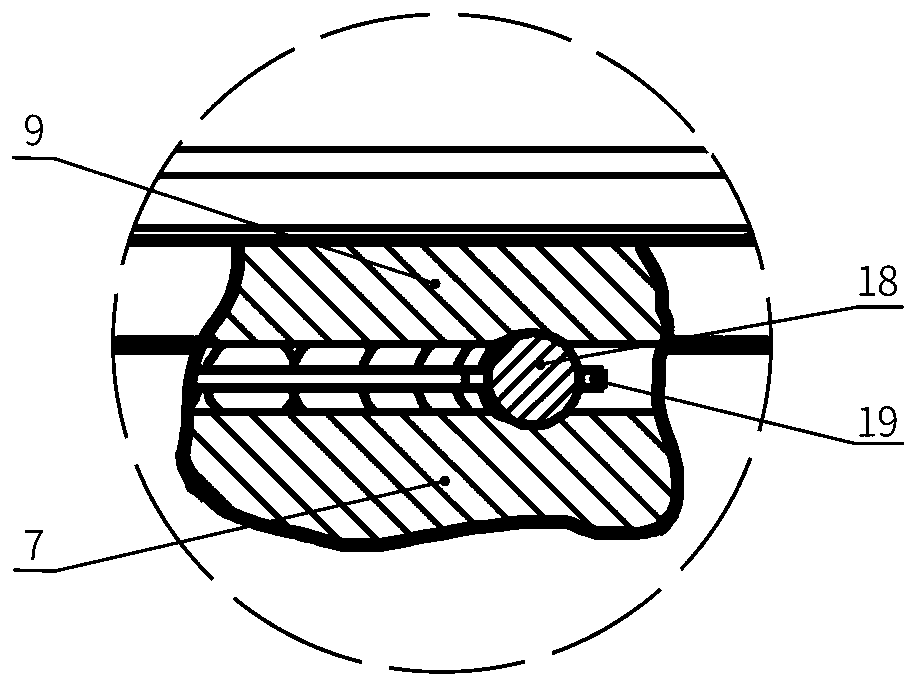

Rotary security inspection device

PendingCN110794467AReduce security check timeImprove user experience and security efficiencyMaterial analysis by transmitting radiationNuclear radiation detectionElectric machineryEngineering

The invention discloses a rotary security inspection device, which comprises a rack, a detection mechanism and a luggage conveying mechanism. A central shaft is fixedly arranged from the top to the bottom of the rack. An arc-shaped baffle plate is arranged at the periphery of the rack. An L-shaped vertical plate of the detection mechanism includes a vertical plate and a transverse plate; a plurality of X-ray receivers are uniformly distributed on the vertical plate and the transverse plate in length directions of the vertical plate and the transverse plate of the L-shaped vertical plate; an X-ray emitter is arranged at the top of the rack above the central shaft and the emitting direction of the X-ray emitter faces the L-shaped vertical plate. A base of the luggage conveying mechanism is the bottom of the circular rack. A rotating disc penetrates the central shaft and is connected with the base through a ball; the rotating disc is driven by a motor and a speed reducing mechanism to rotate around the central shaft; and 3 to 4 lead-containing partition plates rotating synchronously with the rotating disc are fixedly arranged on the rotating disc, wherein the heights of the lead-containing partition plates are from the surface of the rotating disc to the top of the rack. According to the invention, X-ray detection on an object is performed in a rotating manner and the detection space is divided by the baffle plates.

Owner:HEFEI UNIV OF TECH

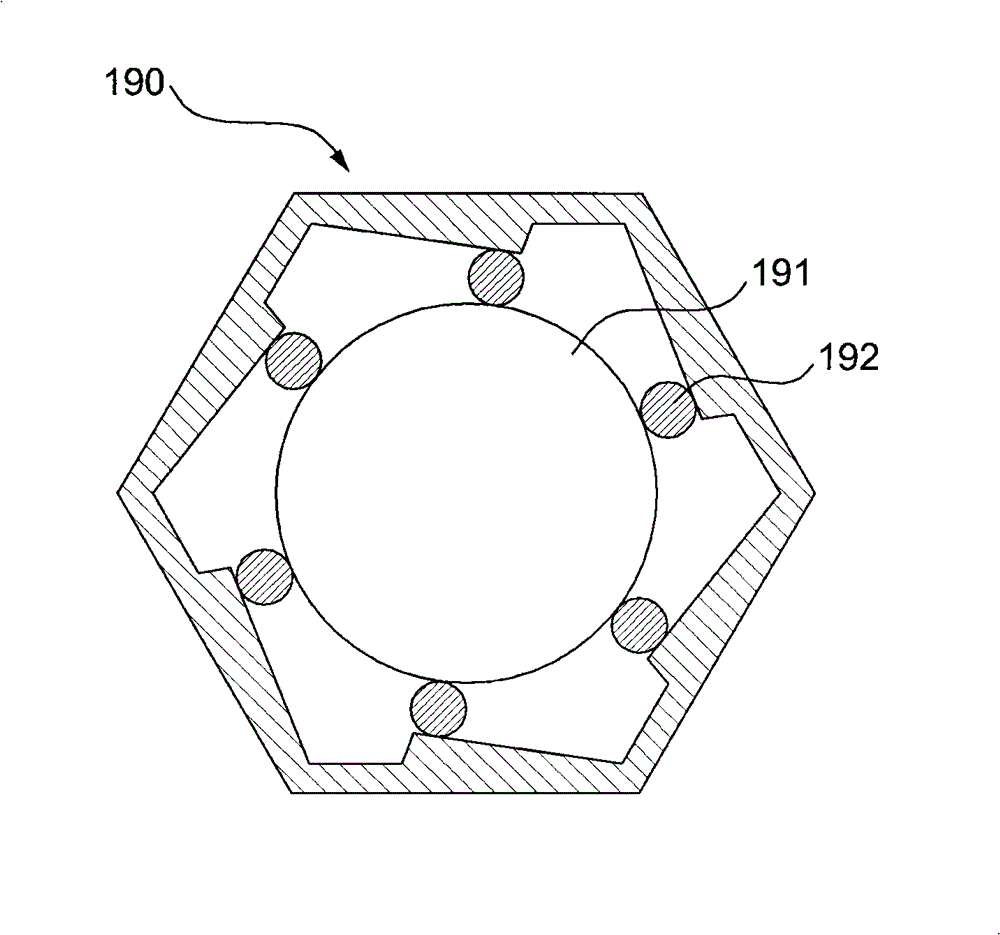

Motorcycle pedal indicating lamp

InactiveCN106379451AReasonable workReduce volumeOptical signalElectrical and Electronics engineering

The invention provides a motorcycle pedal indicating lamp which comprises a polygonal integral indicating lamp body, wherein fixed rings are arranged on two sides of the indicating lamp body, and are connected with an indicating lamp seat; a connecting column is arranged in the indicating lamp seat; an arched pedal is positioned on the rear seat of the motorcycle pedal; fixing holes are formed in two outer sides of the pedal; and the connecting column of the indicating lamp seat is matched with the fixing holes in two outer sides of the arched pedal on the rear seat of the motorcycle pedal. According to the motorcycle pedal indicating lamp, the indicating lamp is arranged on two outer sides of the pedal, which is the bottom wide part of a motorcycle, so that the width of the motorcycle can be seen in night running to avoid collision when two motorcycles encounter, and the distance is limited during overtaking to achieve a warning effect. The motorcycle pedal indicating lamp also has a decorating effect.

Owner:重庆特巴斯科技有限公司

Even twister

The invention provides an even twister. The even twister comprises an even twister frame, a balance plate is arranged at the bottom of the even twister frame, a combined roller is arranged in the even twister frame, a yarn guide plate is fixedly arranged above the combined roller, and a fourth ceramic ring and a fifth ceramic ring independent with each other are arranged on the yarn guide plate. When the yarn guide plate is arranged above the combined roller and two independent ceramic rings are arranged on the yarn guide plate, it is avoided that inner yarns and outer yarns wound around the surface of the combined roller are rubbed against each other, and accordingly the strength loss of twisting yarns is avoided. By arranging the yarn guide plate, the bending angle from the surface of the combined roller to a yarn guide pipe is reduced.

Owner:YICHANG JINGWEI TEXTILE MACHINERY

A diamond automatic welding frame

ActiveCN111604559BLow failure rateReduce use costMetal working apparatusSolder feeding devicesTool bitControl system

The invention relates to the technical field of diamond tool processing and welding, in particular to a diamond automatic welding frame, which includes a machine frame, a PLC controller, a heater, a cutter head rotating conveying module, a cutter head lifting module, a cutter head module, a knife Disc rotation module, cutter head thickness measurement module, solder sheet conveying module, mobile device and cutter head lifting module; the PLC controller, heater, cutter head rotating conveying module, cutter head lifting module, clip The cutter head module, the cutter head rotation module, the cutter head thickness measurement module, the solder sheet conveying module, the mobile device and the cutter head lifting module are erected on the frame; the frame is a diamond automatic welding frame support structure; The PLC controller is a welding frame control system. The present invention changes the traditional way of conveying the cutter head and the solder sheet by setting the cutter head rotary conveying module and the solder sheet conveying module, reduces the failure rate, reduces the use cost, and increases the accuracy and transmission efficiency.

Owner:厦门蓝盾自动化设备有限公司

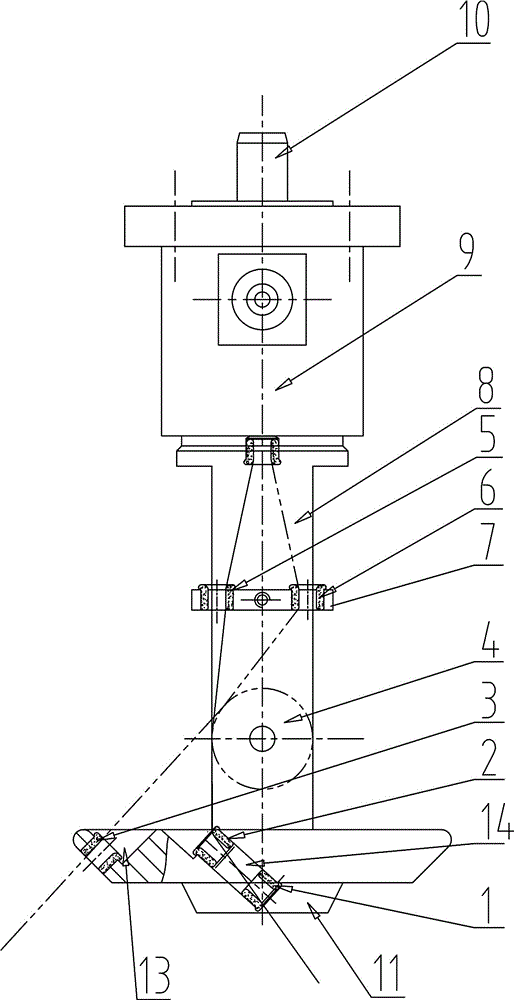

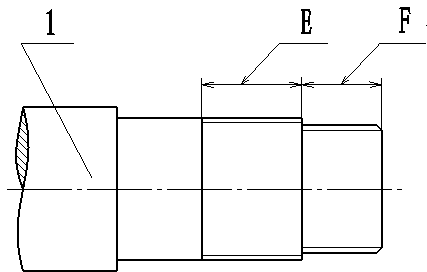

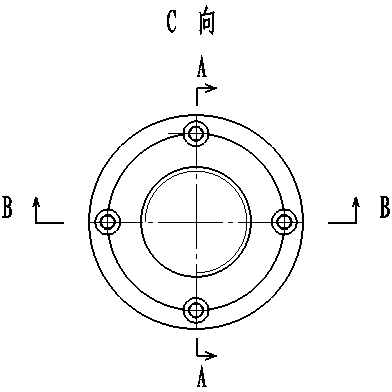

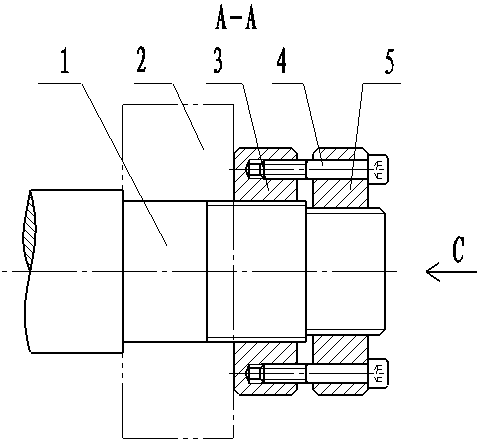

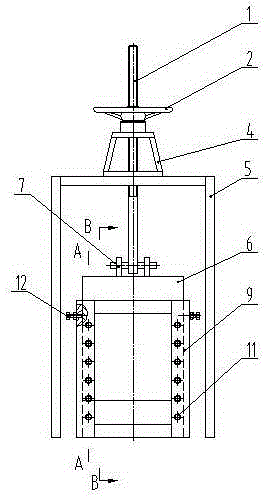

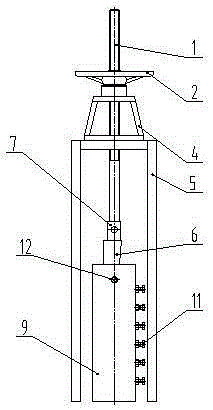

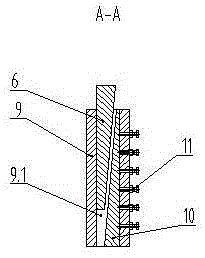

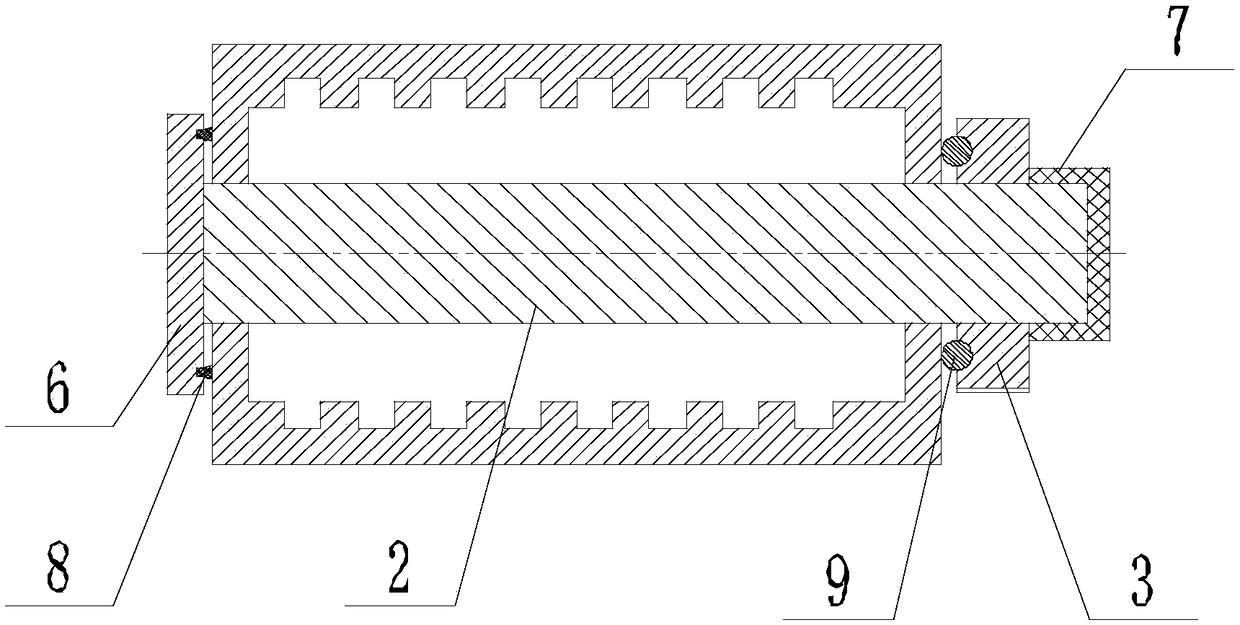

Left-handed and right-handed rotation nut locking device for large-diameter shaft end

The invention discloses a left-handed and right-handed rotation nut locking device for a large-diameter shaft end, which includes a large-diameter shaft lever (1), a clamped body (2) and a locking device, wherein left-handed and right-handed rotation screw threads are arranged at an E section and an F section of an end part of the large-diameter shaft lever (1); the locking device comprises fixing nuts (3), tensioning bolts (4), pushing bolts (6) and locking nuts (5); the fixing nuts (3) are screwed tightly at the E section screw thread; the locking nuts (5) are screwed tightly at the F section screw thread; the distances between the fixing nuts (3) and the locking nuts (5) range from 0.5 mm to 20 mm; and the fixing nuts (3) and the locking nuts (5) are connected by the tensioning bolts (4) and the pushing bolts (6) respectively. The large-diameter shaft end left-handed and right-handed rotation nut locking device is suitable for fastening the large-diameter shaft end.

Owner:CHINA MCC17 GRP

High-performance cargo oil tank sluice valve

InactiveCN106641304AWill not affect sealingAvoid rubbing against each otherSlide valveValve member-seat contactsWear resistantEngineering

The invention discloses a high-performance cargo oil tank sluice valve. The high-performance cargo oil tank sluice valve comprises an adjusting lead screw, a hand wheel, a supporting base, a frame, a sluice plate, lifting lugs, a sluice base and a wedge; the sluice plate is vertically arranged and installed in a vertically formed guide-track groove of the sluice base in an inserted manner from top to bottom, and the sluice plate is in clearance fit with the guide-track groove and can move up and down along the guide-track groove; the wedge is arranged in a fit clearance between the sluice plate and the guide-track groove of the sluice base in the medium flowing direction; the sluice plate and the wedge are provided with mutually wedged tapered wedge surfaces respectively, and the wedge surface of the wedge is shaped like a big-end-down wedge; as further improvements, the mutually wedged tapered wedge surfaces of the sluice plate and the wedge are each coated with a wear-resistant layer, bonding surfaces of the sluice plate and the sluice base are also coated with the wear-resistant layer, the portion, on the back face of the wedge, of the groove wall of the guide-track groove of the sluice base is provided with multiple adjusting bolts, and the groove walls on the two sides of the guide-track groove are each provided with a locking bolt. The high-performance cargo oil tank sluice valve is small in operating torque, resistant to wear and good in sealing reliability.

Owner:JIANGSU ZHONGHAO MARINE VALVE MFG

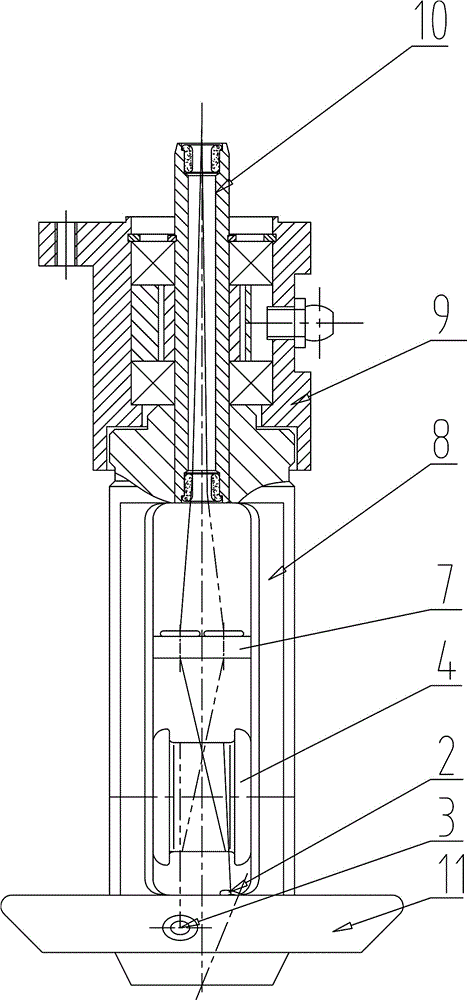

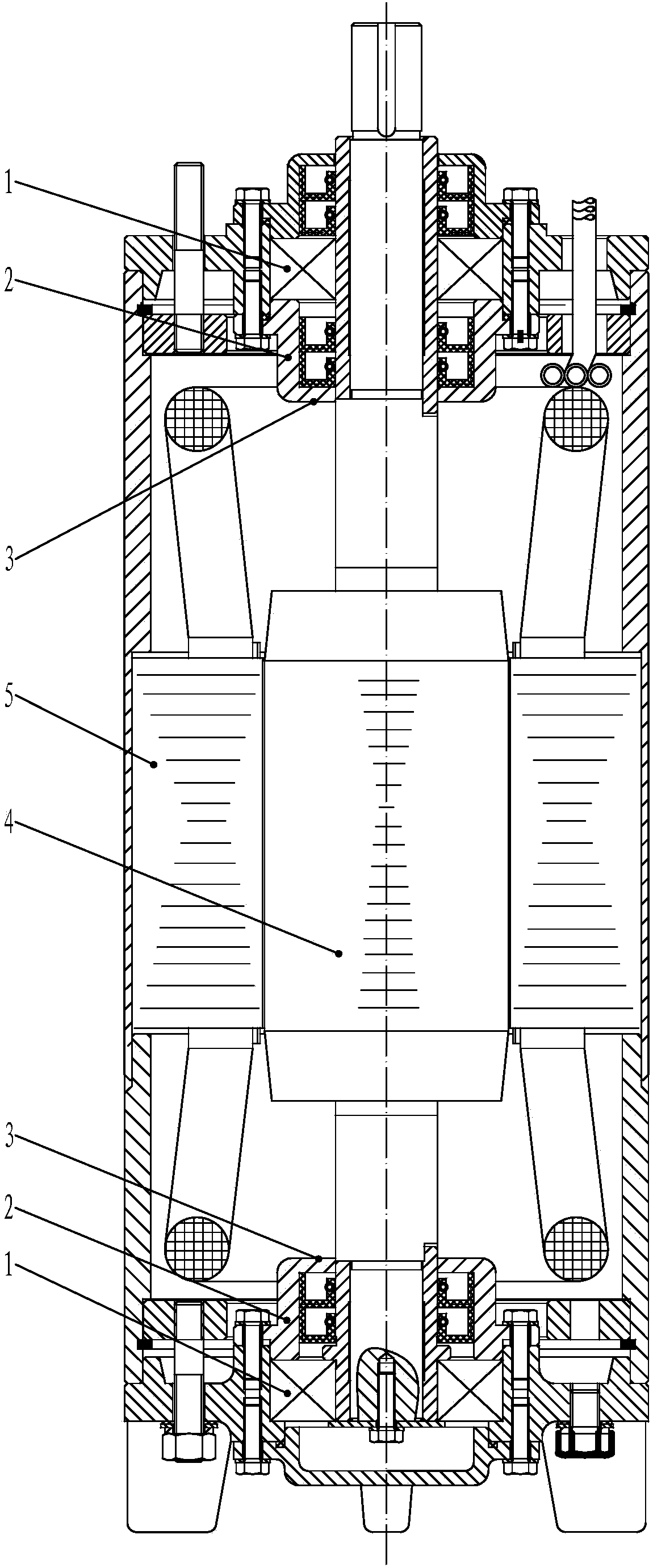

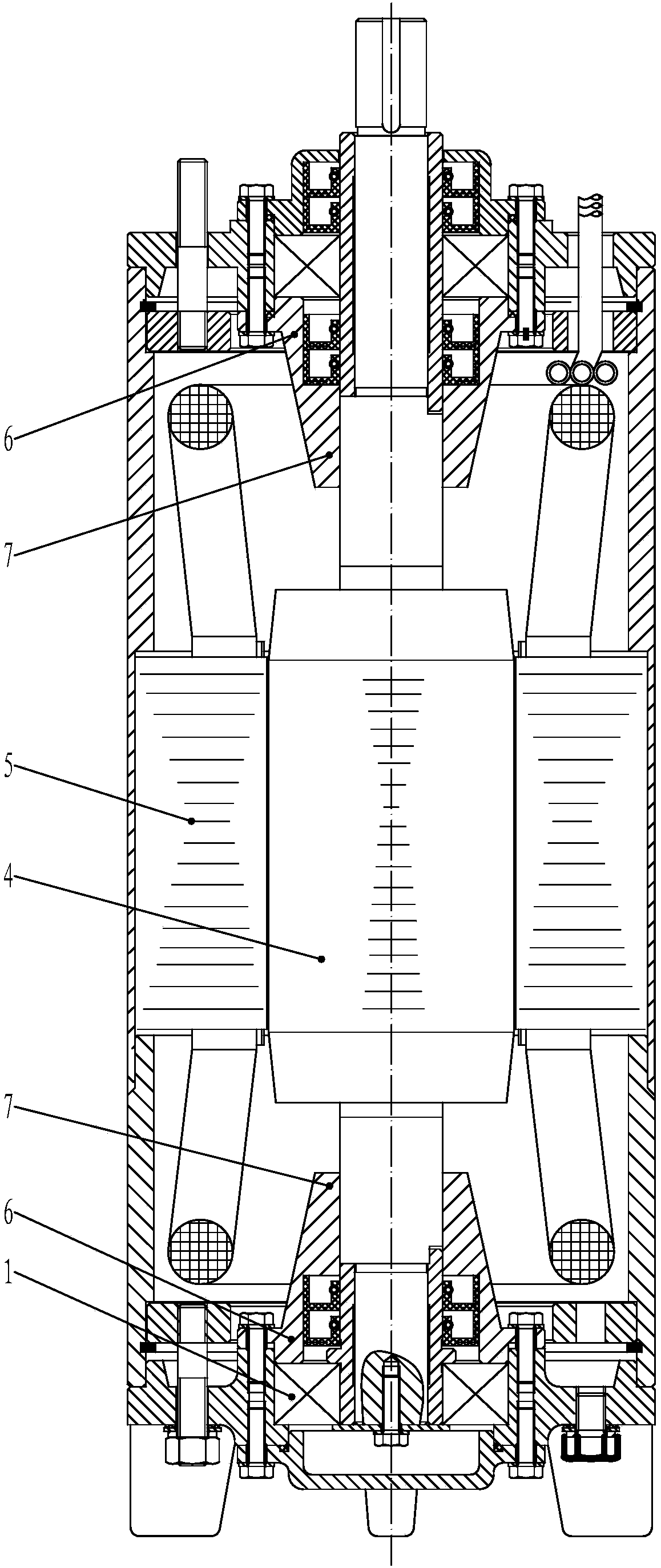

Bearing gland at end of submersible pump rotor shaft

InactiveCN108626160AAvoid rubbing against each otherReduce maintenance costsPump componentsPump installationsEngineeringSubmersible pump

The invention provides a bearing gland at the end of a submersible pump rotor shaft. The bottom end of the bearing gland is thickened in the wall thickness direction, the thickened bottom end of the bearing gland forms a protective jacket relative to the rotor shaft, and an inner hole of the protective jacket is in sliding fit with the diameter of the rotor shaft. After a bearing is abraded and damaged, the protective jacket of the bearing gland can play a temporary supporting role for the rotor shaft, a rotor cannot swing, the situation that the rotor and a stator scratch and rub each other is avoided, and a role of protecting a motor is achieved.

Owner:WEINAN GENERAL EQUIP MFG

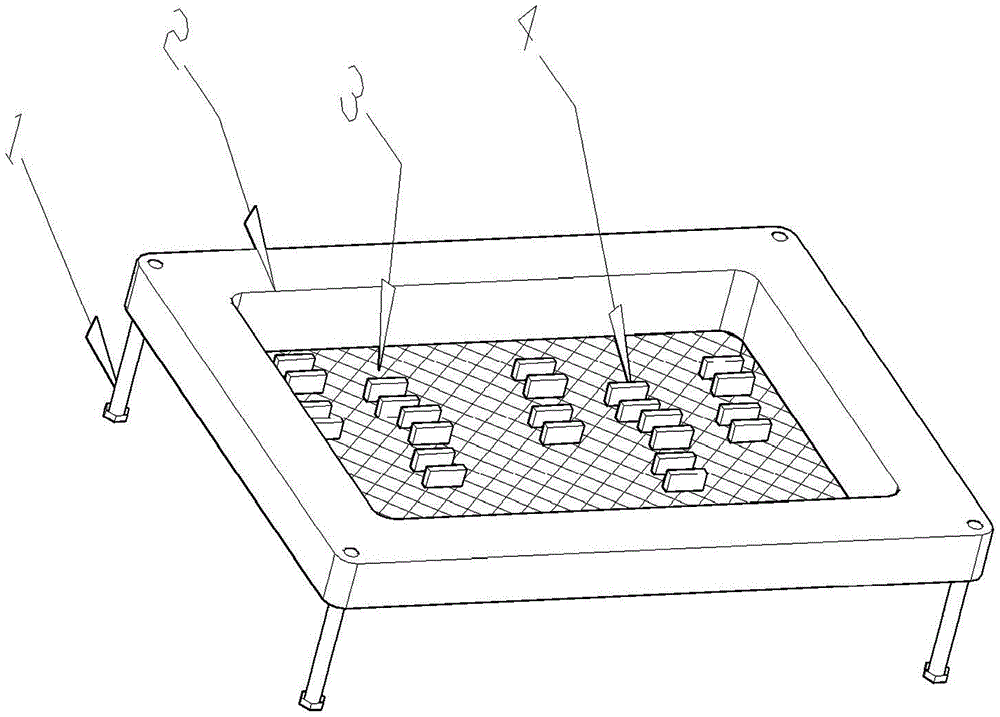

An auxiliary device for plasma cleaning of components

ActiveCN103433261BAvoid accumulationAvoid rubbing against each otherCleaning processes and apparatusUltraviolet lightsSilica gel

The invention relates to a plasma cleaning auxiliary device for components and parts. The bottom of a frame (2) is connected with a screen mesh (3) to serve as the bottom of a tray, a partition plate (4) is arranged in the middle of the frame (2) to divide the tray into two areas, and 704 or 705 silica gel (3a) is coated on the screen mesh (3) in one area. When the plasma cleaning auxiliary device is used, an element (4) cleaned in a double-side mode is arranged on the screen mesh (3) on the left area, an element (5) cleaned in a single-side mode is arranged on the silica gel (3a) on the right area, and finally a cleaning device is arranged into a plasma cleaning machine to be cleaned. The plasma cleaning auxiliary device has the advantages that by means of the action of leakage holes of the screen mesh, plasma can bombard the elements from all sides, and the cleaning efficiency is remarkably improved. The screen mesh can dredge and disperse airflow to prevent the elements from being blown by the airflow, piled and rubbed. The silica gel can absorb the components and the parts to prevent the components and the parts from being blown by the airflow, piled and rubbed. Compared with a method using a blue film or a UV film to fix the elements, the plasma cleaning auxiliary device removes a special film shifting machine and a special ultraviolet light machine and saves cleaning cost.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Motorcycle foot pedal indicator light

A motorcycle foot pedal indicator light comprises a polygonal integral indicator light body. Two sides of the indicator light body are provided with fixing rings connected with an indicator light base, and a connection column is arranged in the indicator light base. A motorcycle foot pedal rear seat is provided with an arch pedal, two outer sides of the pedal are provided with fixing holes, and the connection column of the indicator light base is matched with the fixing holes in the two outer sides of the arch pedal of the motorcycle foot pedal rear seat. By mounting of indicator lights on pedal two outer sides which are bottom width parts of a motorcycle, the width of the motorcycle in night running is visible, collision of two motorcycles in meeting is avoided, distance limiting in overtaking is realized, an alarming effect is achieved, and a decorative effect is achieved as well.

Owner:重庆动沃机车产业有限公司

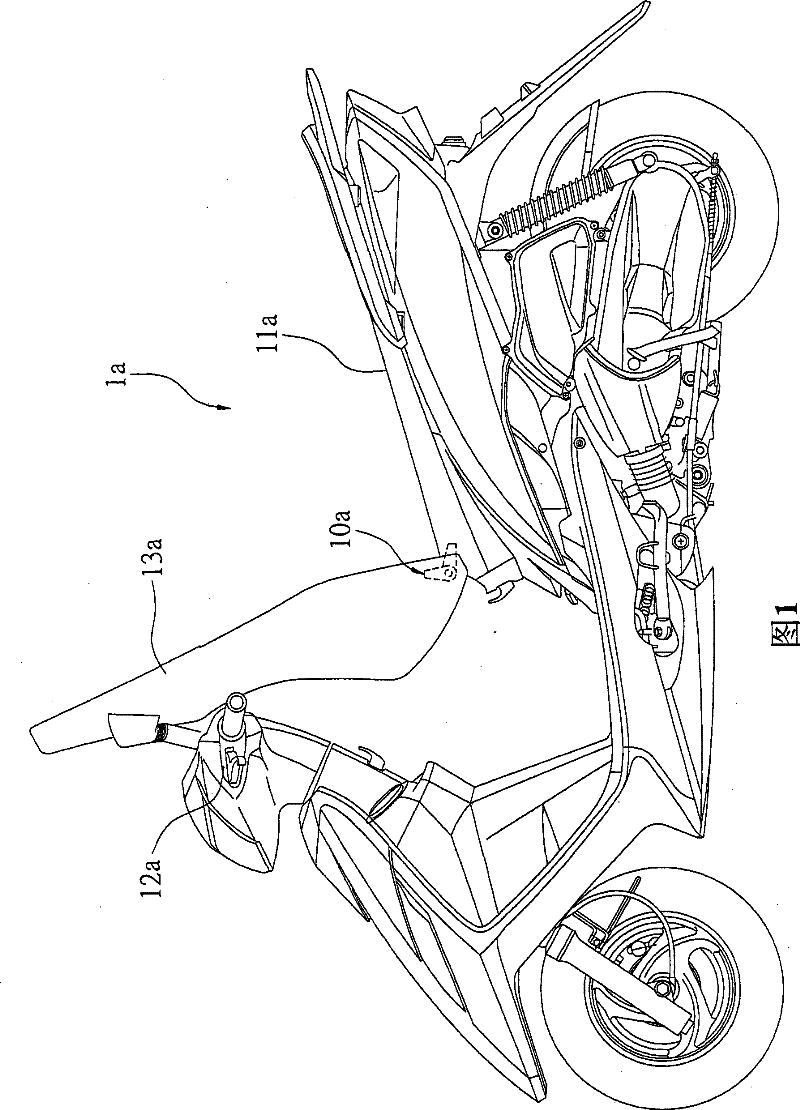

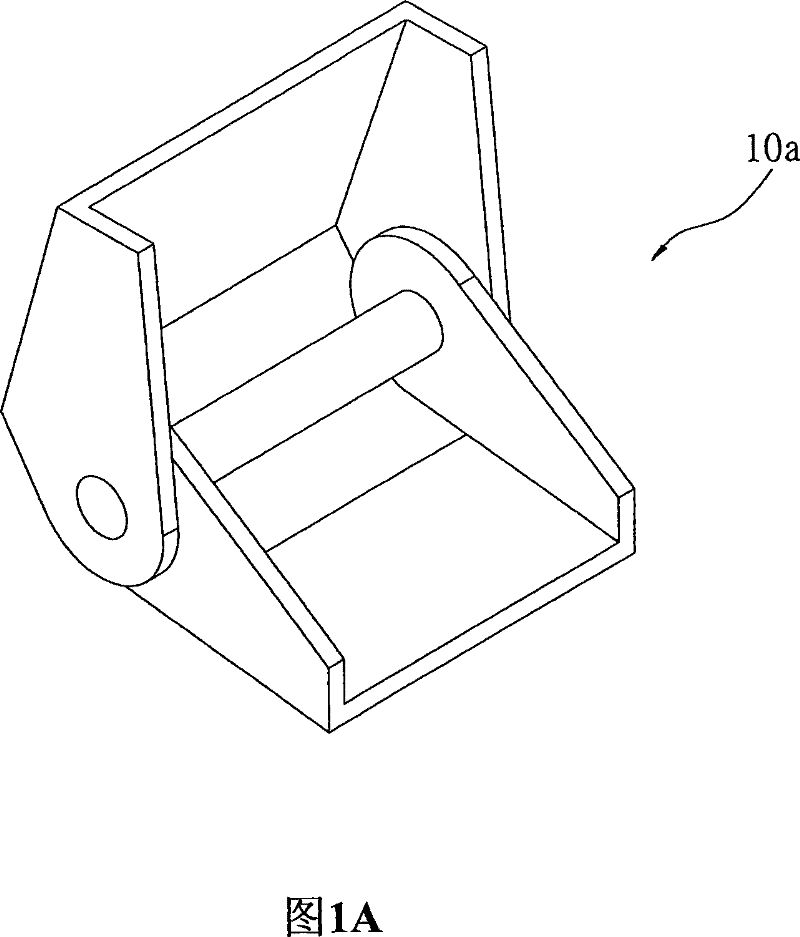

Positioning device for cushion of automatic bicycle

ActiveCN101468668BImprove convenienceAvoid rubbing against each otherCycle saddlesEngineeringCushion

Owner:YAMAHA MOTOR CO LTD

Warp-feeding device applicable to no-bending fabric weaving

ActiveCN103343418BAvoid rubbing against each otherMaintain flat cross-section shapeLoomsYarnEngineering

A warp-feeding device applicable to no-bending fabric weaving is characterized by comprising a warp supply device (2), wherein the warp supply device is composed of a plurality of single-yarn shafts (7) which are consistent in specification and independent from each other, and a single warp strand (3) twines one single-yarn shaft (7). The single-yarn shafts (7) are tightly close to one another, arranged in parallel, penetrate through the same supporting shaft and fixed on a weaving machine base (1) to form the warp supply device which penetrates through the same heald frame of a no-bending fabric weaving system. According to the warp-feeding device applicable to no-bending fabric weaving, independent warp-delivery single-yarn shafts are applied, mutual frication and squeezing among warp can be effectively avoided, and therefore the warp-feeding device applicable to no-bending fabric weaving is beneficial to keeping a flat sectional shape of broaden yarn. Moreover, a tension heavy punch which 'can slip' is matched with the warp supply device and forms a warp tension control device can adjust the single-yarn state immediately, enables the tension of piece yarn to be even, reduces wear and broken yarn, and improves the weaving efficiency and the quality of fabric.

Owner:南京海拓复合材料有限责任公司

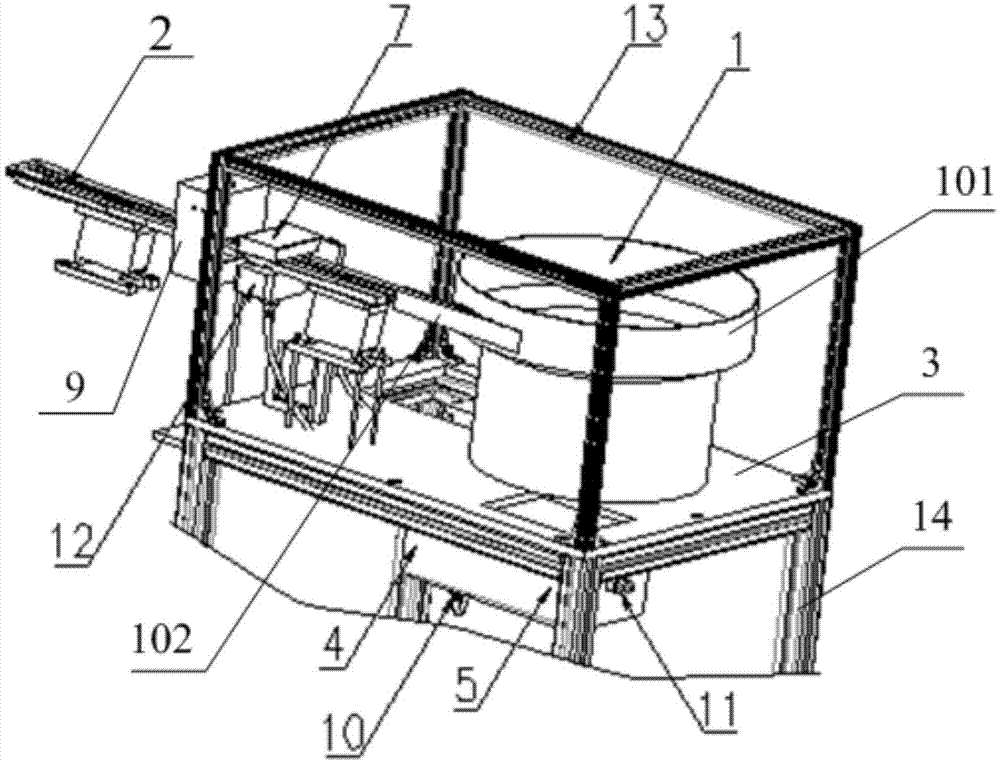

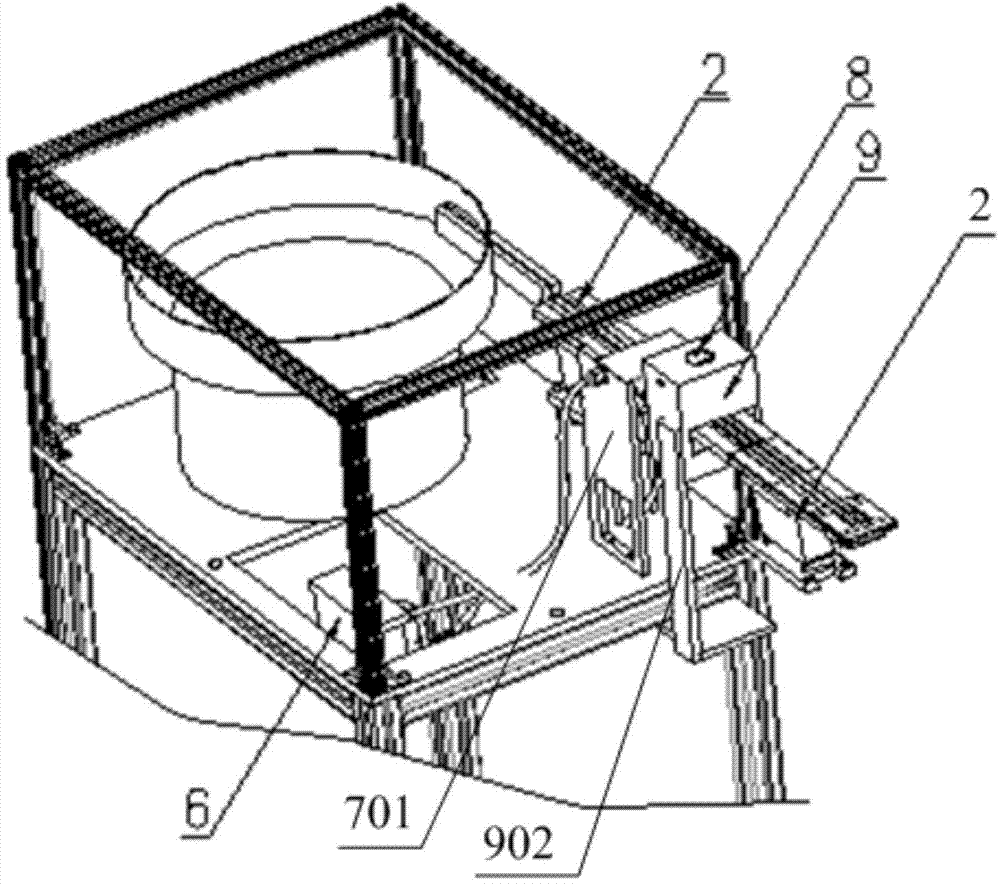

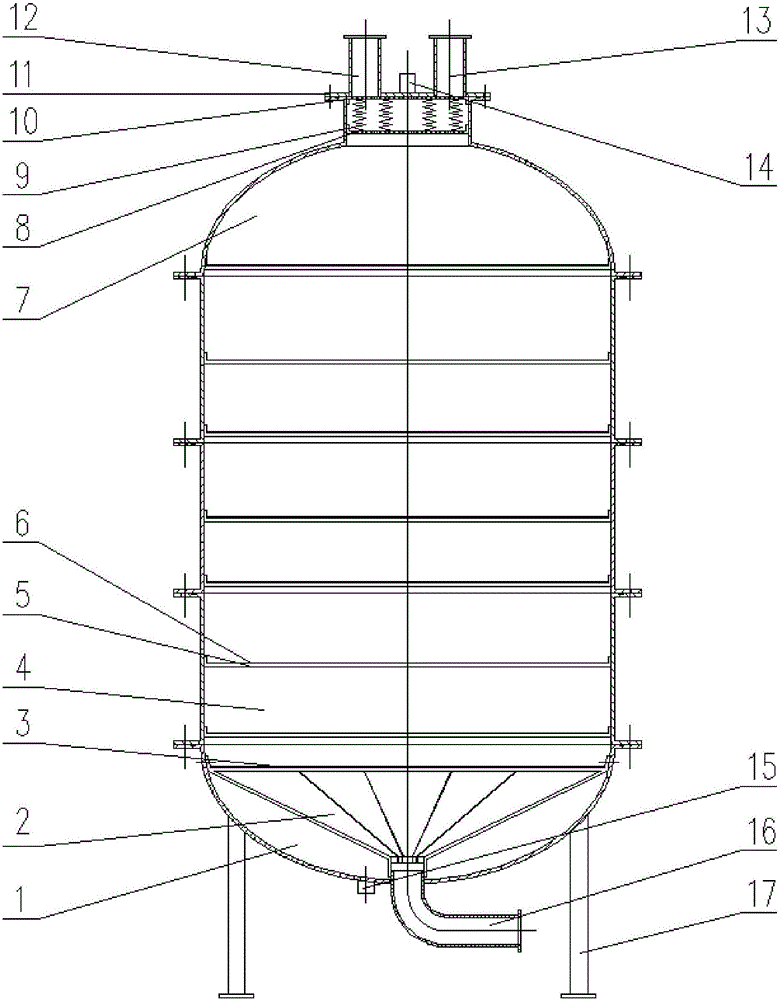

Novel adsorption device tower for coal mine gas concentration

InactiveCN105879578AIncrease or decrease the quantity at willGuaranteed to passGaseous fuelsDispersed particle separationSorbentCoal mine methane

The invention discloses a novel adsorption device tower for coal mine gas concentration. The adsorption tower includes multiple sections of freely combinable cylinder structures. A gas inlet formed in the lower end of an adsorption tower body is provided with a conical flow distributing part, and a metal net is arranged at the upper portion of a flow distributor and can evenly distribute raw material gas. Multiple layers of metal nets for outputting static electricity and supporting bodies are arranged in the adsorption tower body and are fixed to the adsorption tower body. An exhaust gas discharging port, a gas outlet and an explosion door are arranged in the upper end of the adsorption tower body. A combination of a press plate bottom, a spring and a press plate top is arranged in the upper end of the adsorption tower body and used for applying an appropriate pressure to an adsorbent. The novel adsorption device tower overcomes the shortcomings of the prior art, and the height of the freely combinable adsorption tower can be adjusted according to different types of adsorbents, the concentration and humidity of different types of raw material gases and the parameter requirements of finished products gases to meet the demand for gas concentration under the condition of complicated and varied parameters.

Owner:HEFEI DESIGN & RES INST LLC OF COAL IND

Method for preventing water purification diaphragm from being damaged

InactiveCN108911045AAvoid rubbing against each otherPrevents damage to self-supporting membersSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisEngineeringDust particles

The invention discloses a method for preventing a water purification diaphragm from being damaged. The method comprises the following steps: step A: loosening and removing a nut from a screw; step B:moving a baffle away from a bearing box until the screw completely leaves a through hole; step C: placing water purification diaphragm assemblies in the bearing box in turn, and keeping two ends of each water pufiication diaphragm assembly placed in a pair of guide grooves opposite to each other; and step D: enabling the end, away from the baffle, of the screw to pass through the through hole in one side of the bearing box, then to pass through the water purification diaphragm assemblies, and to pass through the through hole in the other side of the bearing box, and then enabling the end of the screw to be in threaded connection with the nut. Compared with simple stacking of water purification diaphragm assemblies, the water purification diaphragm assemblies are borne in the method, thus friction and scratch of the water purification diagram assemblies caused by small dust particles on the surface of the water purification diagram assemblies are avoided and self-supporting components are prevented from being damaged by external forces due to the absence of a protective shell.

Owner:龚平

Full-automatic front face and back face gummed paper attaching machine device

InactiveCN110092175AAvoid rubbing against each otherAvoid pollutionControl devices for conveyorsArticle deliveryManipulatorHand joint

The invention discloses a full-automatic front face and back face gummed paper attaching machine device which comprises an attaching machine body. A full-automatic assembly line conveying positioningdevice arranged in the attaching machine body make products effectively positioned and conveyed during attaching machining, colliding between products is effectively avoided, and ordered machining attaching of the products can be effectively ensured. In addition, due to a full-automatic mechanical hand joint overturning device arranged in the attaching machine, overturning work can be conducted onthe products effectively so that when a man-machine interaction touch screen controls a full-automatic gummed paper conveying device and a full-automatic gum taking device to perform attaching on theproducts, secondary conveying is not needed for achieving attaching work, and therefore pollution to the products during secondary conveying is effectively avoided; and the attaching efficiency on front faces and back faces of the products can be effectively improved, the machining precision of the products is greatly improved, and the defects in the prior art are effectively overcome.

Owner:深圳市宏利源自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com