Rotary security inspection device

A rotary, security inspection technology, applied in the direction of measuring devices, nuclear radiation exploration, instruments, etc., can solve the problems of being rejected, and achieve the effects of shortening the time of security inspection, blocking leakage, and optimizing the security inspection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

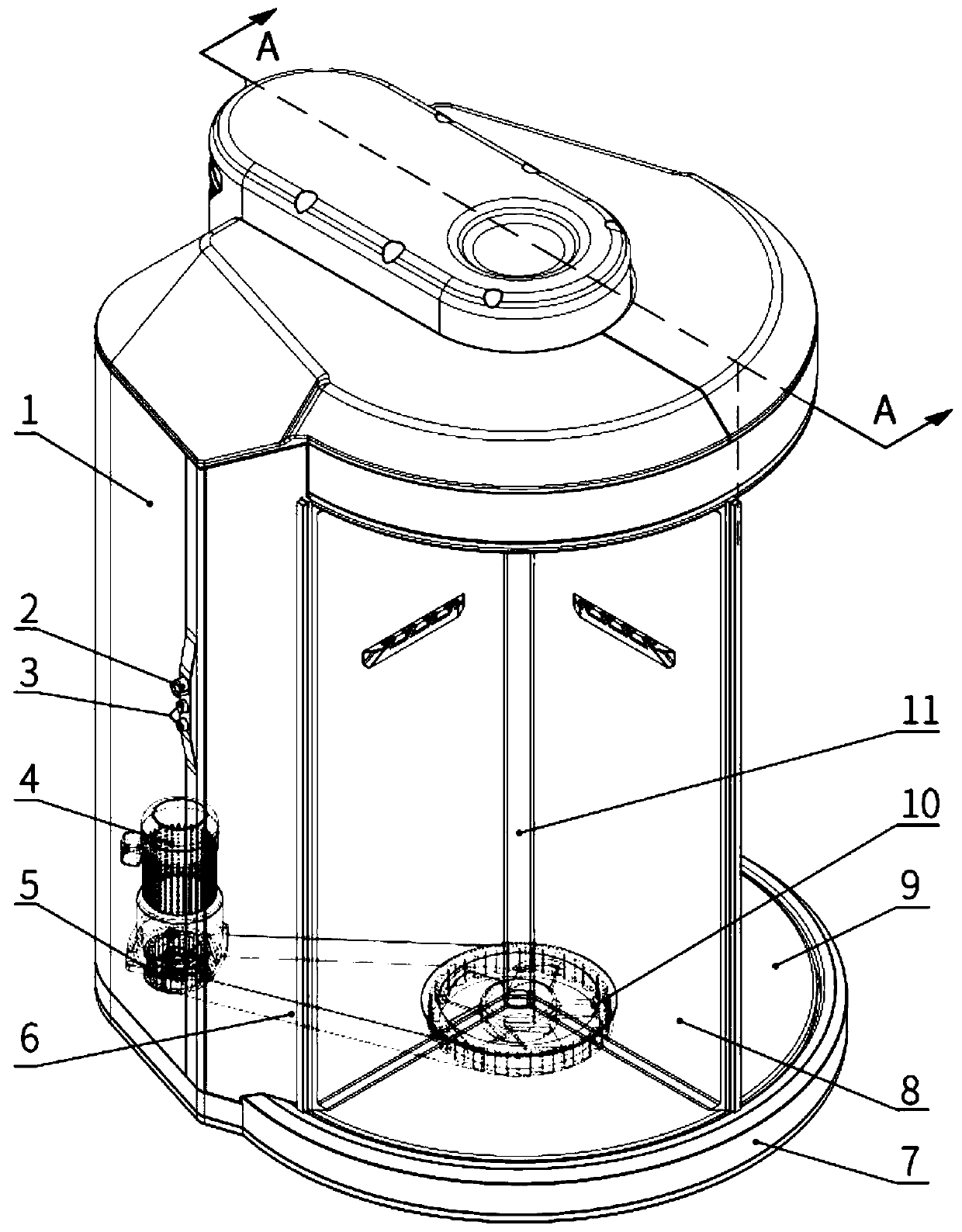

[0033] figure 1 It is a rotary security inspection device, which is composed of a frame 1, a detection mechanism and a baggage transmission mechanism.

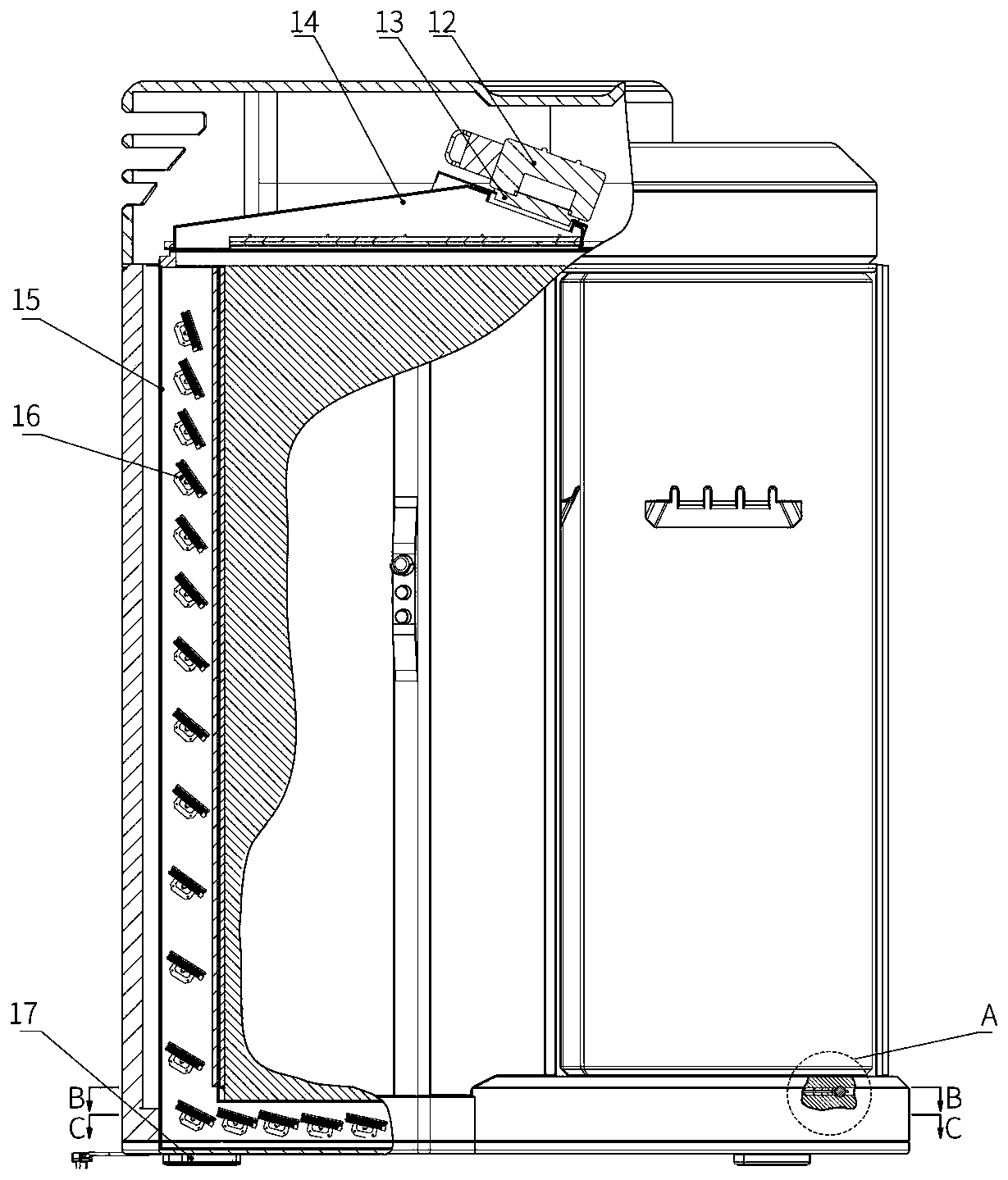

[0034] figure 2 yes figure 1 The A-A sectional view of the detection mechanism is composed of an X-ray emitter 12, a front collimation support 13, a rear collimation support 14, an L-shaped baffle 15 and an X-ray receiver 16.

[0035] The frame 1 is in the shape of a cylinder, which is composed of a circular top, a circular bottom and an arc-shaped baffle, and a central axis 11 is set from the center of the top to the center of the bottom.

[0036] A top cover is arranged on the top of the frame, and an X-ray emitter 12 , a front collimation support 13 and a rear collimation support 14 are arranged inside the top cover. Wherein the X-ray emitter is arranged on the upper part of the frame, and the front collimation support and the rear collimation support are arranged in front of the X-ray emitter.

[0037] The curved baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com