Plasma cleaning auxiliary device for components and parts

A technology of plasma cleaning and auxiliary devices, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of high cleaning cost, low cleaning efficiency, and easy damage of small-sized components, so as to save cleaning costs and avoid mutual The effect of rubbing, avoiding accumulation and mutual rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

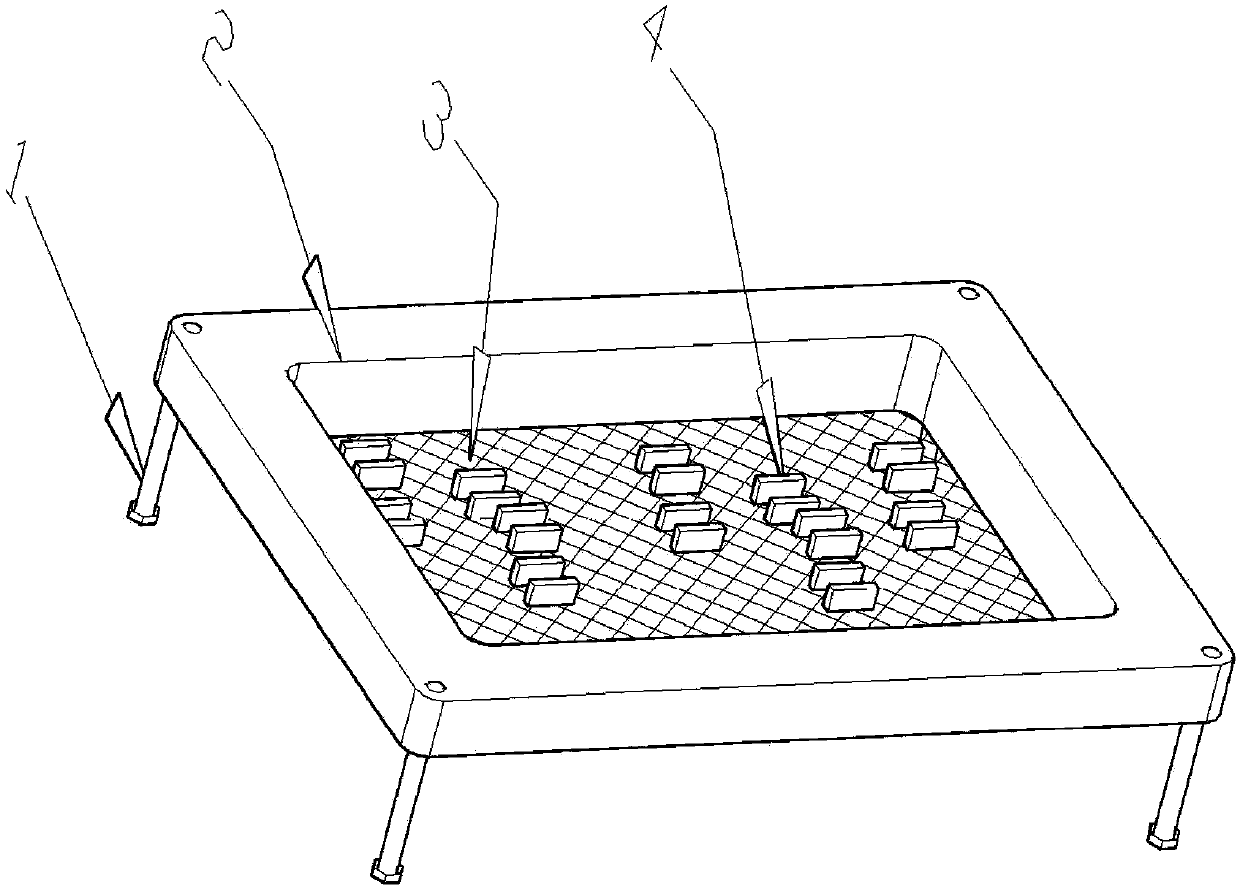

[0021] The overall structure of a plasma cleaning auxiliary device for components provided by the present invention is shown in Figure 1:

[0022] It includes a tray composed of a bracket 1 , a rectangular frame 2 and a tray bottom 3 . Wherein, the bracket 1 is connected with the frame 2 by threads or glued to play a supporting role, and the stainless steel wire mesh 3 of a certain mesh is used as the bottom of the plate and connected with the frame 2 through a stretching process to form a tray with a wire mesh at the bottom.

Embodiment 2

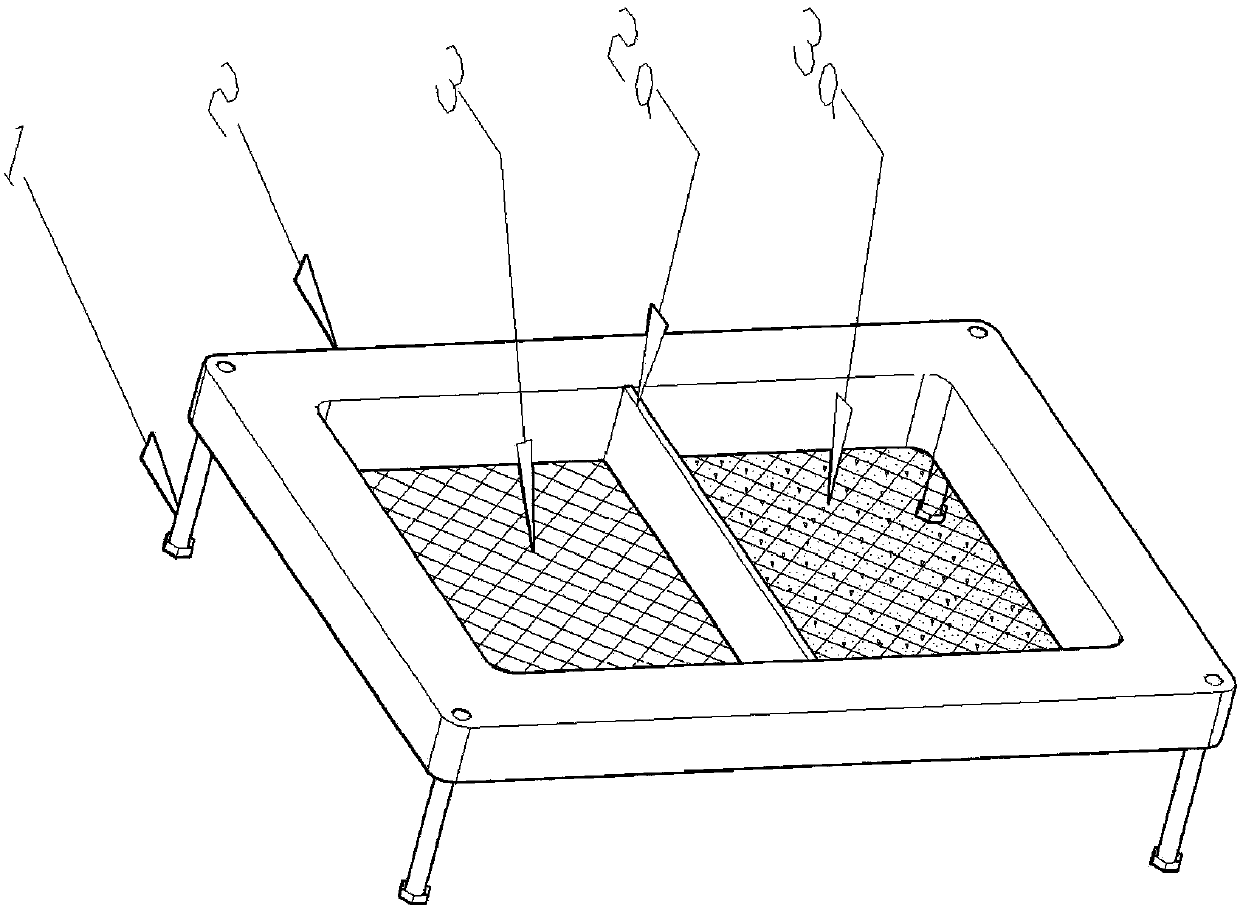

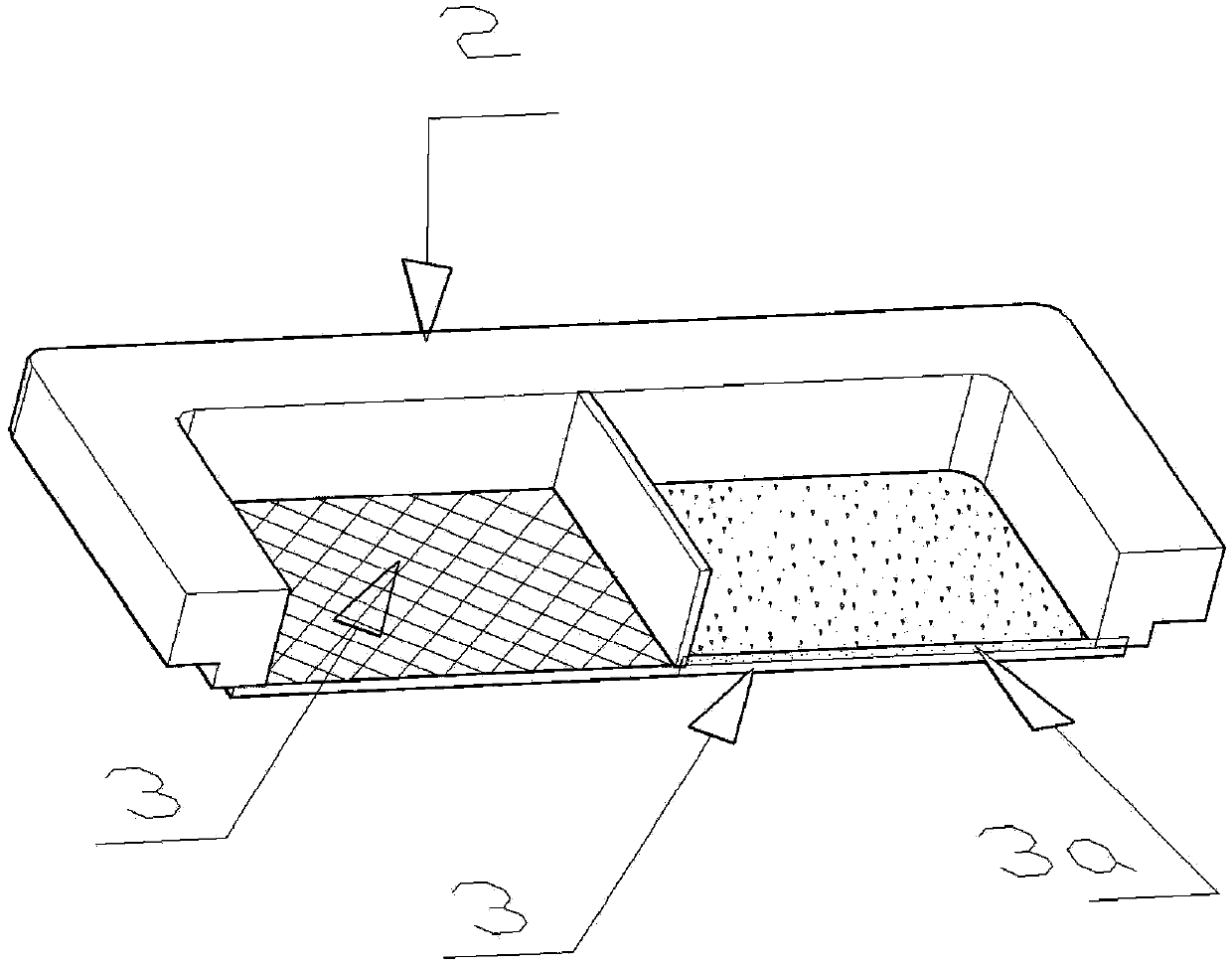

[0024] Such as figure 2 , image 3 As shown, a partition 2a can also be set in the middle of the frame 2 to divide the tray into two areas, one area retains the screen 3 as the bottom of the plate, and the other area uses 704 or 705 silica gel 3a on the bottom screen 3, which is smooth, Spread evenly on screen.

[0025] Figure 4 is the present invention adopts figure 2 The schematic diagram of the cleaning device holding and cleaning components is shown.

[0026] When in use, first place the element 4 to be cleaned on both sides on the screen 3 in the left area, and place it in a single layer to avoid the accumulation and mutual friction of the elements; then put the single-sided cleaning element 5 on the silica gel 3a in the right area, Arranged in a single layer to avoid component accumulation and mutual friction. Then put the cleaning device of the present invention into the plasma cleaning machine, and complete the cleaning process through pumping, air inflation, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com