Corrosion prevention, high temperature resistance, steel wire armored and tearing resistance flat cable

A technology of steel wire armoring and high temperature resistance, which is applied in the direction of flat/ribbon cables, insulated cables, cables, etc., and can solve the problem of high mechanical, physical and chemical properties of the outer protective layer of the cable, easy damage to the outer sheath, and safety Hidden dangers and other problems, to achieve the effect of strengthening the overall strength, preventing corrosion, good high temperature resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

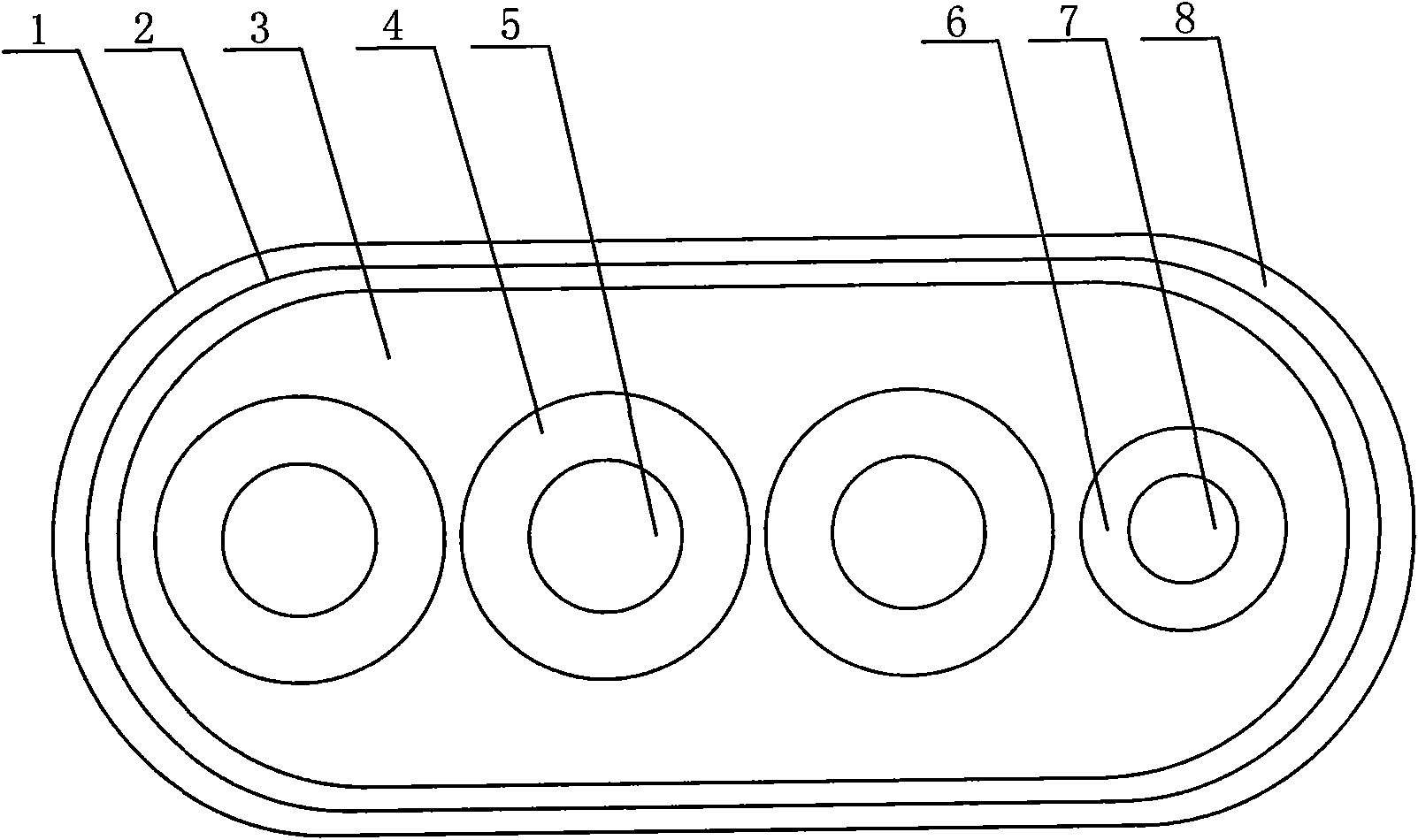

[0011] Such as figure 1 Among them, an anti-corrosion and high-temperature resistant steel wire armored tensile tear flat cable includes a sheath 3, a main core conductor 5, a main core insulator 4, a ground core conductor 7 and a ground core insulator 6 are installed in the sheath 3, and the sheath The sheath 3 is provided with a steel wire braided armor 2 , the steel wire braided armor 2 is provided with a fiber outer coating 1 , and an adhesive 8 is provided between the sheath 3 , the steel wire braided armor 2 and the fiber outer coating 1 .

[0012] The steel wire braided armor 2 is made of galvanized steel wire.

[0013] The fiber outer layer 1 is made of glass fiber.

[0014] The adhesive 8 is epoxy resin.

[0015] A steel wire braided armor 2 braided by galvanized steel wire is arranged outside the sheath 3 of the flat cable, and the diameter of the galvanized steel wire used is 0.2-0.35mm, and a fiber outer layer made of glass fiber is arranged on the outer layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com