Module for adding protective agents to contacts and automatic assembly machine and assembly method for contacts

A protective agent and protection technology, which is applied to furnace components, conveyor objects, transportation and packaging, etc., can solve problems such as cracking, mutual friction, and scratches on the silver point protective layer, so as to achieve high production efficiency, avoid waste, and improve production efficiency. The effect of degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

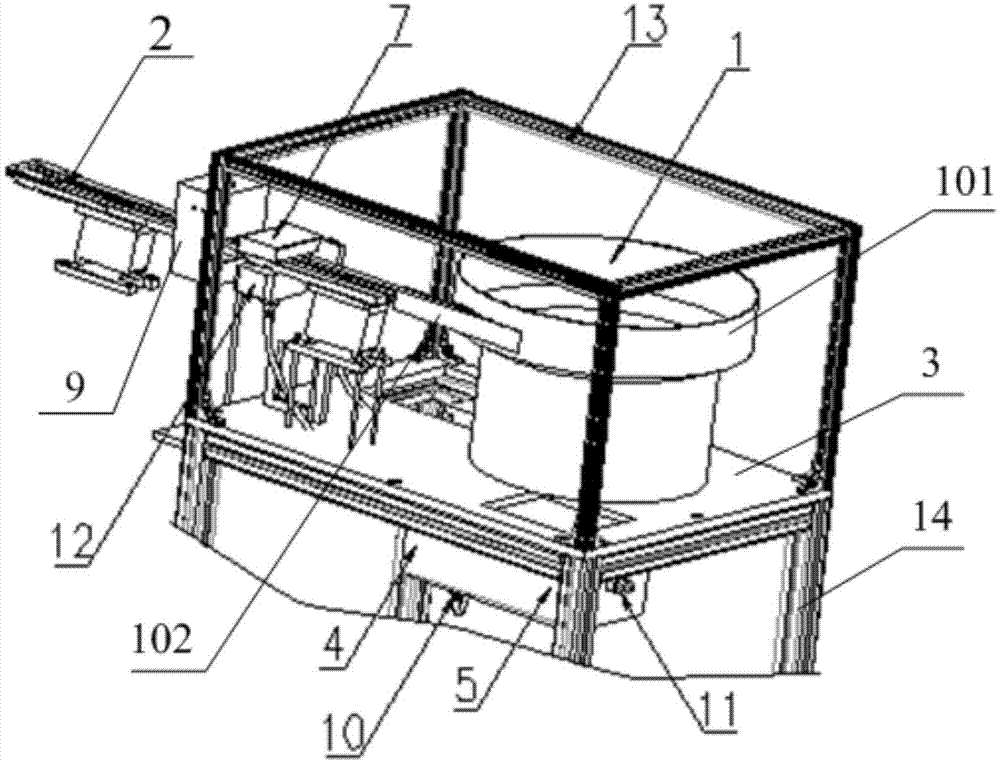

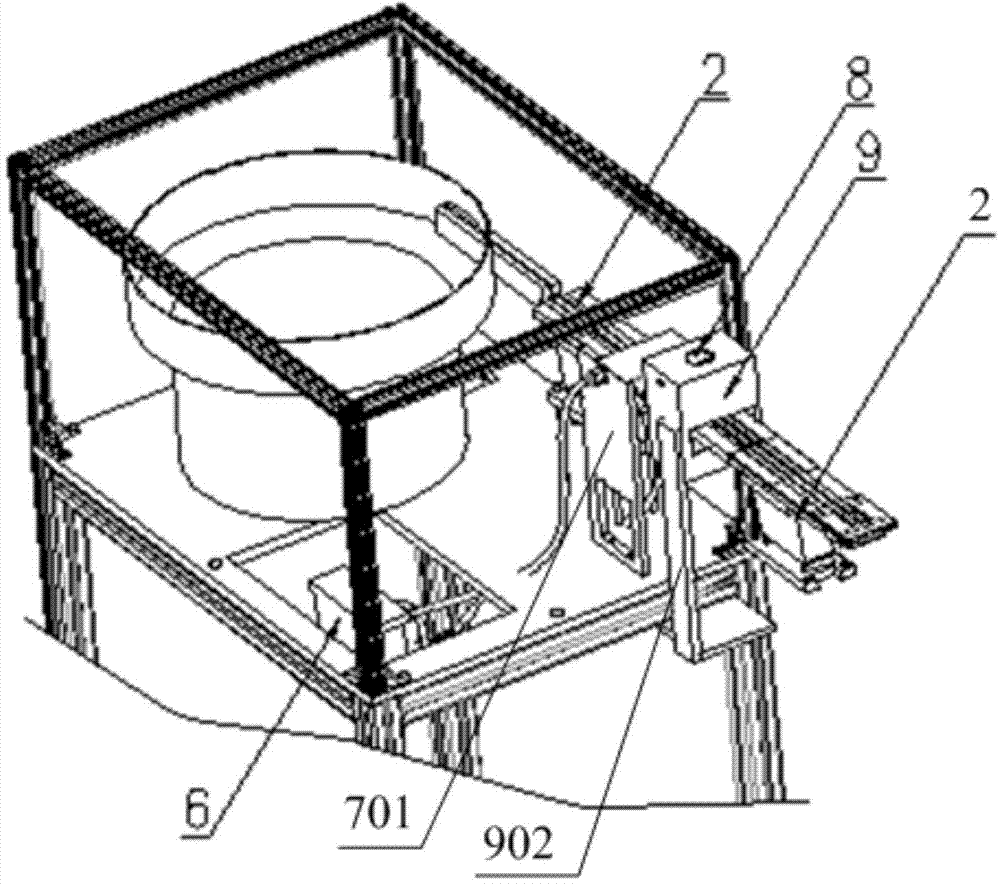

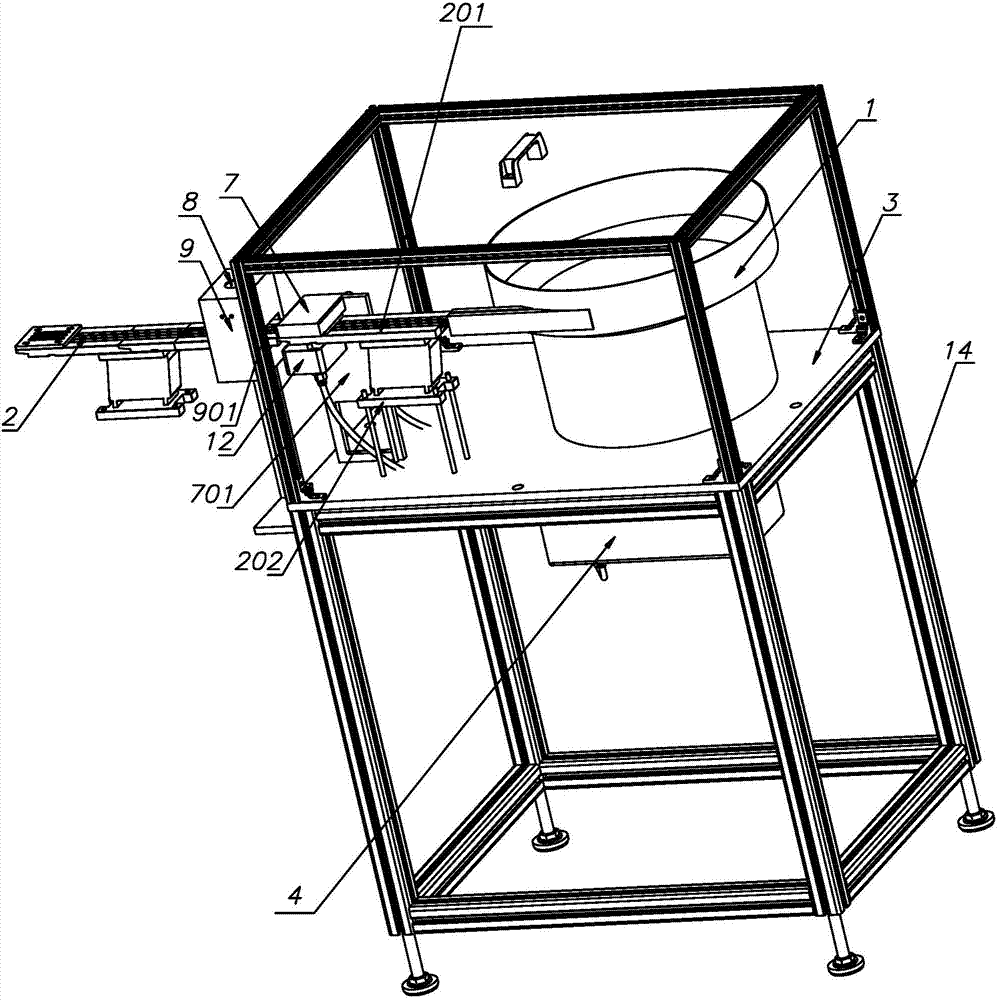

[0029] The following is attached Figures 1 to 6 The given examples further illustrate the specific implementation of the contact plus protective agent module of the present invention. The contact protection agent module and contact automatic assembly machine of the present invention are not limited to the description of the following embodiments.

[0030] Such as Figure 1-3 As shown, a contact assembly machine includes a contact arrangement machine 1 and a contact assembly station (not shown in the figure), and a contact protection device is provided between the contact arrangement machine 1 and the contact assembly station. The agent module, the contact plus protective agent module includes a contact feeder 2 that can transfer contacts, and the two ends of the conveyor belt of the contact feeder 2 can be connected with the contact arrangement machine 1 and the contact assembly station respectively; Corresponding positions on the conveyor belt of the head feeder 2 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com