Fire hose cleaning device

A technology of fire hose and cleaning device, applied in fire rescue and other directions, can solve the problems of unclean washing, low manual labor, time-consuming and laborious, etc., and achieve the effect of low manual labor, high cleaning efficiency, and avoiding backlog.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

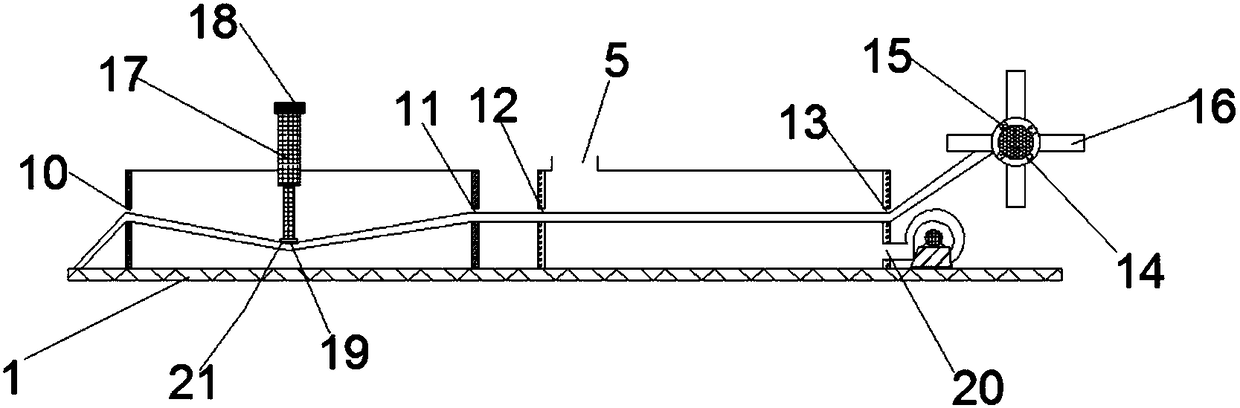

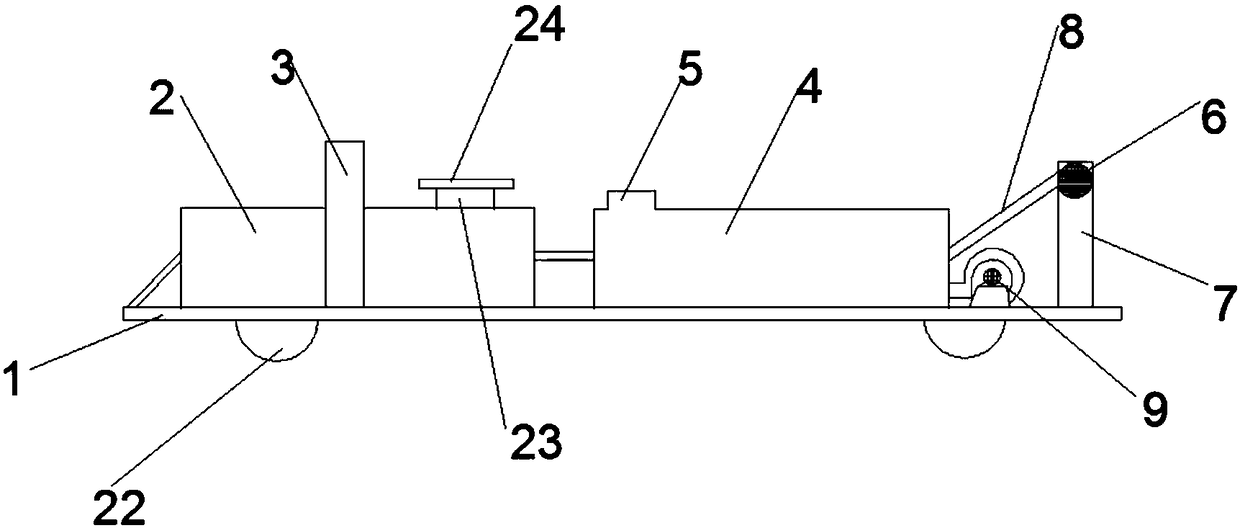

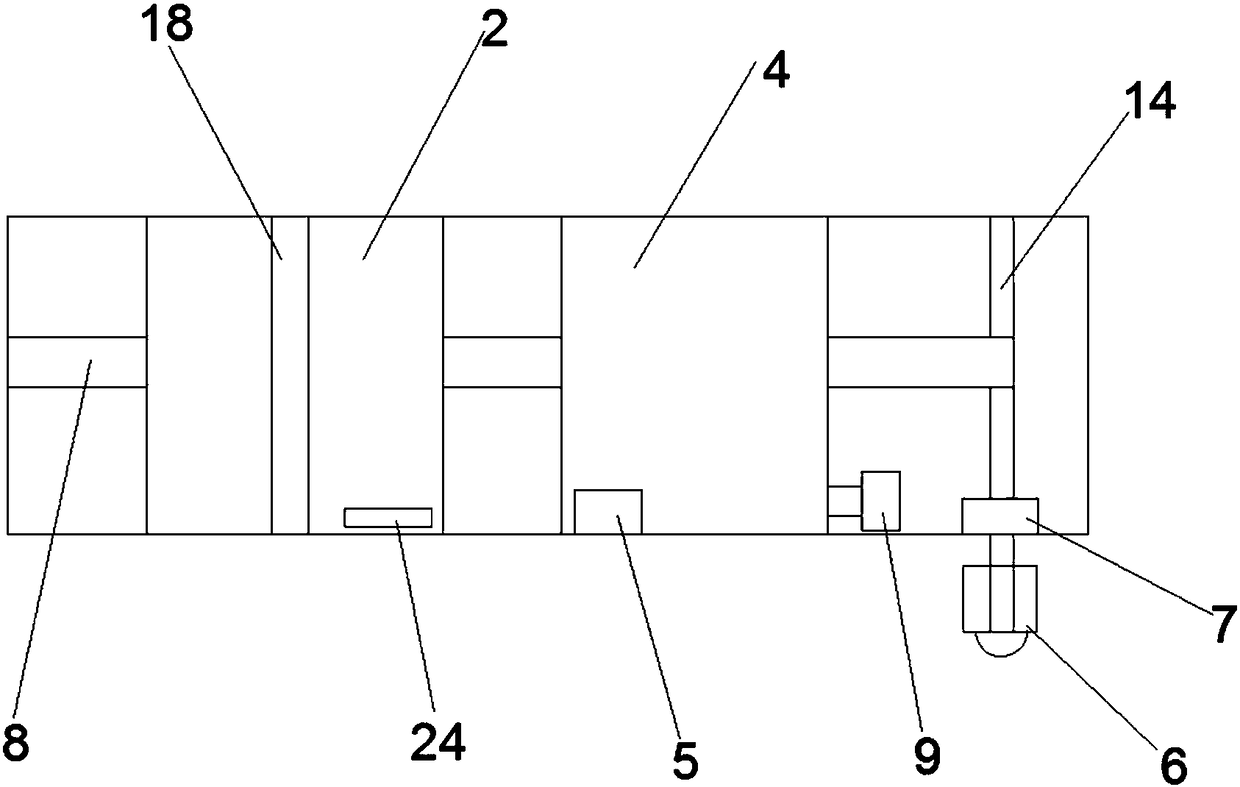

[0032] refer to Figure 1-3 , a fire hose 8 cleaning device, including a base 1, the base 1 is provided with a cleaning tank body 2, a winding mechanism for winding the fire hose after cleaning, the cleaning tank body 2 includes a rectangular tank structure, and the cleaning tank The two opposite side walls of the body 2 are respectively provided with a first through hole 10 and a second through hole 11 for the fire-fighting water pipe to pass through the cleaning tank, and the two sides of the cleaning tank body 2 perpendicular to the first through hole 10 and the second through hole 11 Columns 3 are arranged on both sides, horizontal plates 18 are arranged between the columns 3, telescopic parts 17 are arranged between the horizontal plates 18 and the cleaning tank body 2, one end of the telescopic parts 17 is connected with the horizontal plate 18, and the other end is connected with a pressure rod 21 , the pressing rod 21 is provided with bristles 19 .

[0033] Working pr...

Embodiment 2

[0035] Based on Example 1, with reference to Figure 1-3 , the telescopic member 17 of this embodiment includes an electric telescopic rod.

[0036]When the fire hose 8 needs to be cleaned, the pressure rod 21 connected to the electric telescopic rod can be pushed down by the electric telescopic rod, which is more convenient through electric operation and lower labor force.

Embodiment 3

[0038] Based on Example 1, with reference to Figure 1-3 , the winding mechanism of this embodiment includes a bracket 7 arranged on the base 1, the bracket 7 is provided with a rotating shaft 14, and the rotating shaft 14 is provided with a detachable connecting piece 15 for connecting the winding frame of the fire hose 8, and the rotating shaft 14 is provided with a driving mechanism 6 for driving the rotating shaft 14 to rotate.

[0039] The fire hose 8 winding frame is installed on the rotating shaft 14 through the detachable connector 15, and one end of the fire hose 8 passing through the first through hole 10 and the second through hole 11 is connected to the fire hose 8 winding frame , the rotating shaft 14 is driven to rotate through the driving mechanism 6, so that the fire hose 8 winding frame installed on the rotating shaft 14 is rotated, and then the cleaned fire hose 8 is wound on the fire hose 8 winding frame, which can realize The effect of winding while cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com