Winding machine and winding method

A winding method and a technology of winding dies, which are applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as inability to wind wires, disorderly winding, and wire entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the best mode for carrying out the present invention will be described based on the drawings.

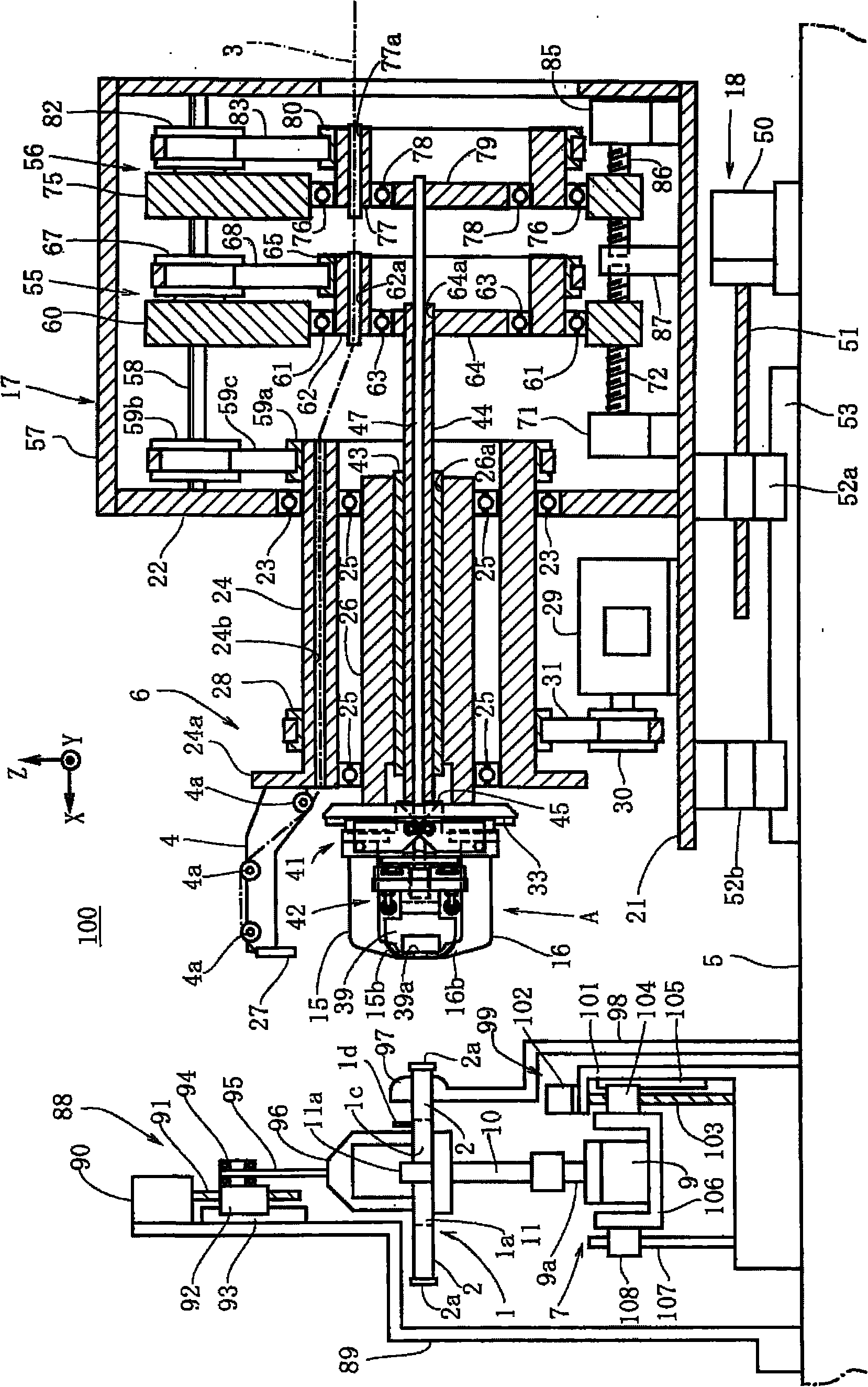

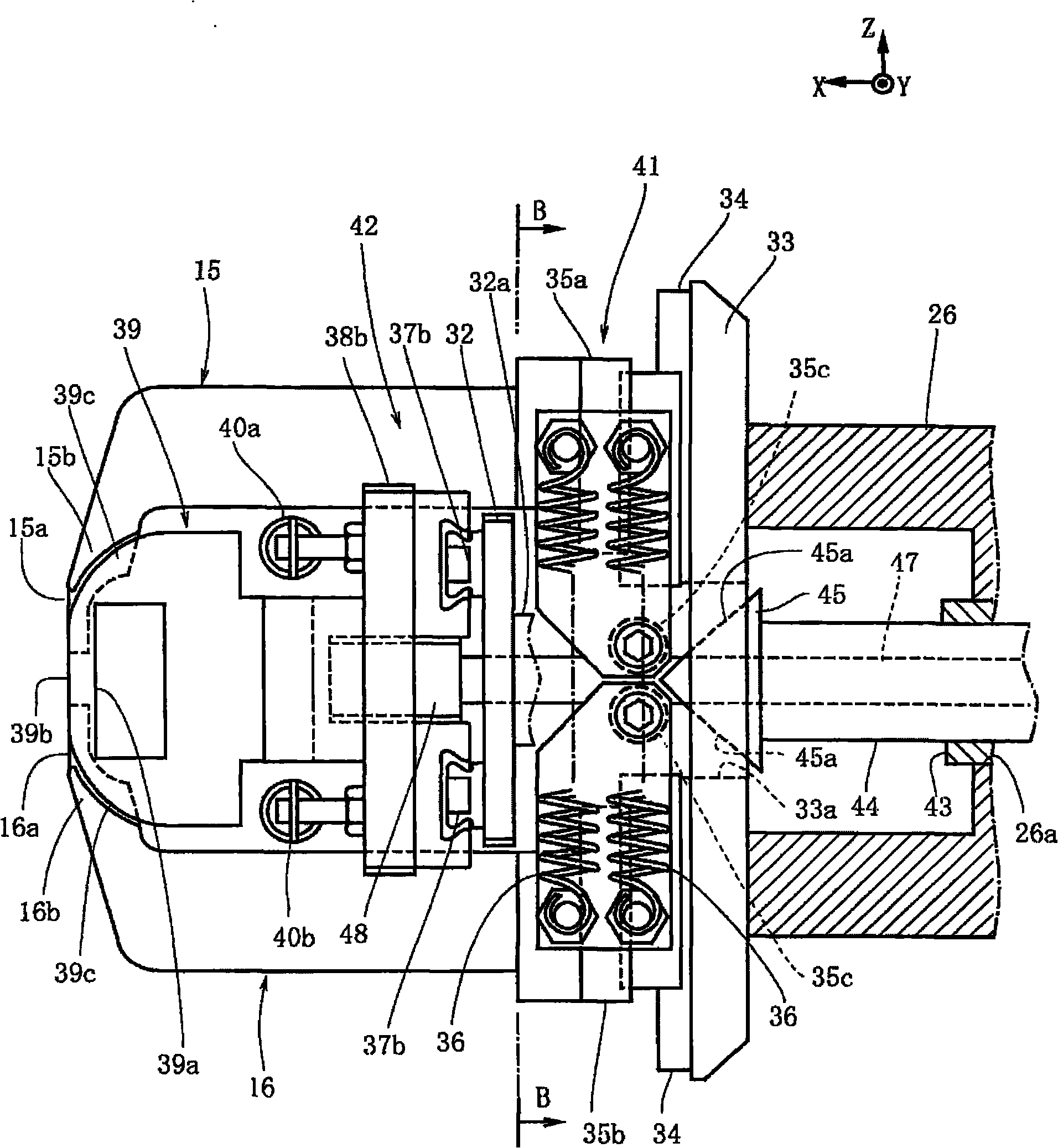

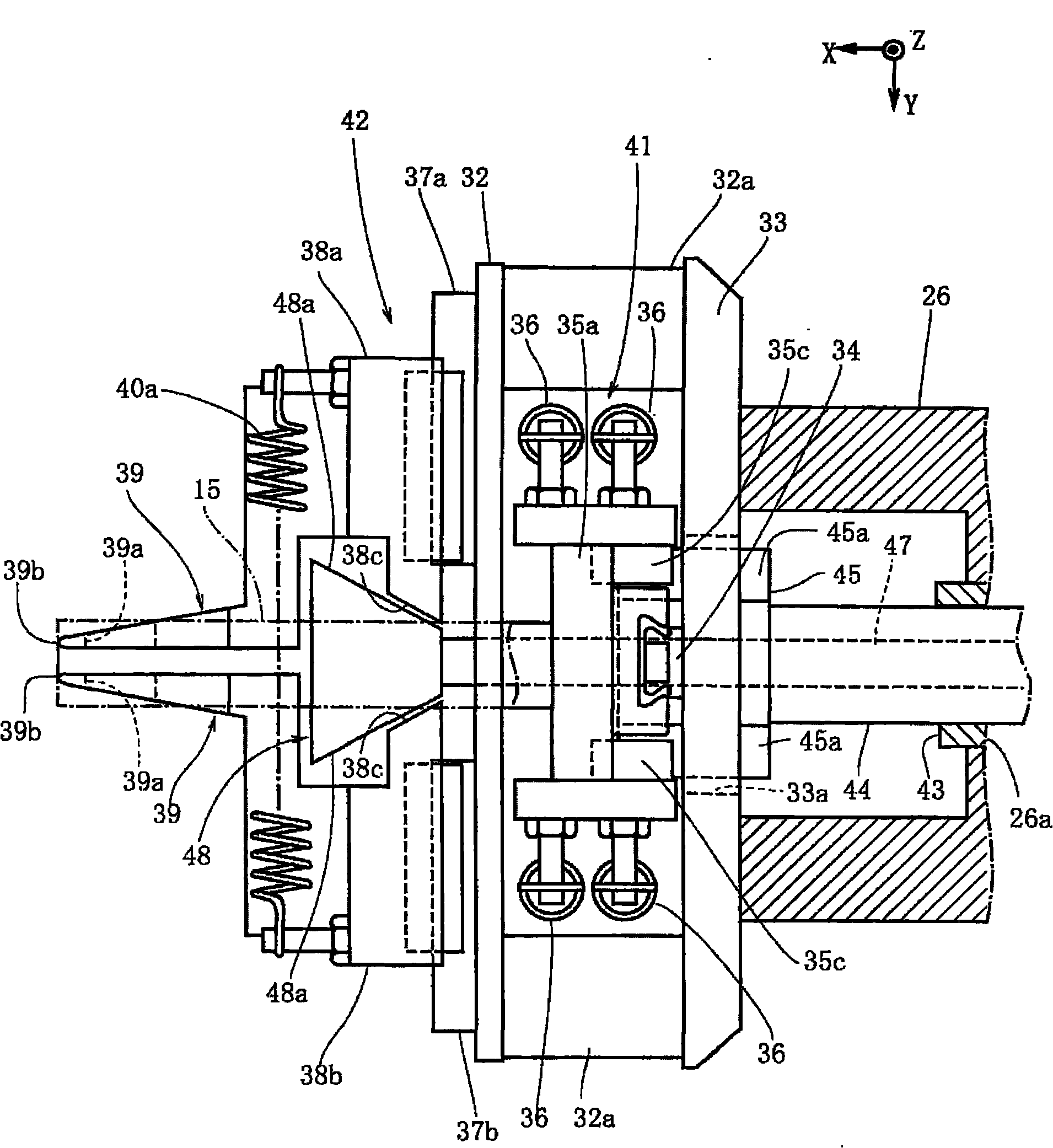

[0038] figure 1 Shows the winding device 100 of the present invention. The winding device 100 is a device that winds a multi-layer wire 3 around a plurality of magnetic poles 2 of a multi-pole armature 1 (stator) that constitutes an engine or a motor. It uses a flying wire that rotates around the magnetic pole 2 while leading out the wire 3 A flying fork type winding device for winding the fork 4. The multipole armature 1 in this embodiment is an armature including a ring portion 1a and 18 magnetic poles 2 projecting radially outward from the ring portion 1a ( Image 6 Middle represents 7 magnetic poles). Such as Image 6 As shown, an opening is formed between the magnetic poles 2 of the multi-pole armature 1 to form a slot 1b. The cross section of the magnetic pole 2 is quadrangular, and the outer peripheral surface of the magnetic pole 2 is composed of four smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com