Drum with broken line grooves

A reel and rope groove technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of uneven rope arrangement, shorten the life of the wire rope, cannot guarantee the position of the fixed wire rope when it returns, and reduce the disordered rope, The effect of prolonging the service life and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

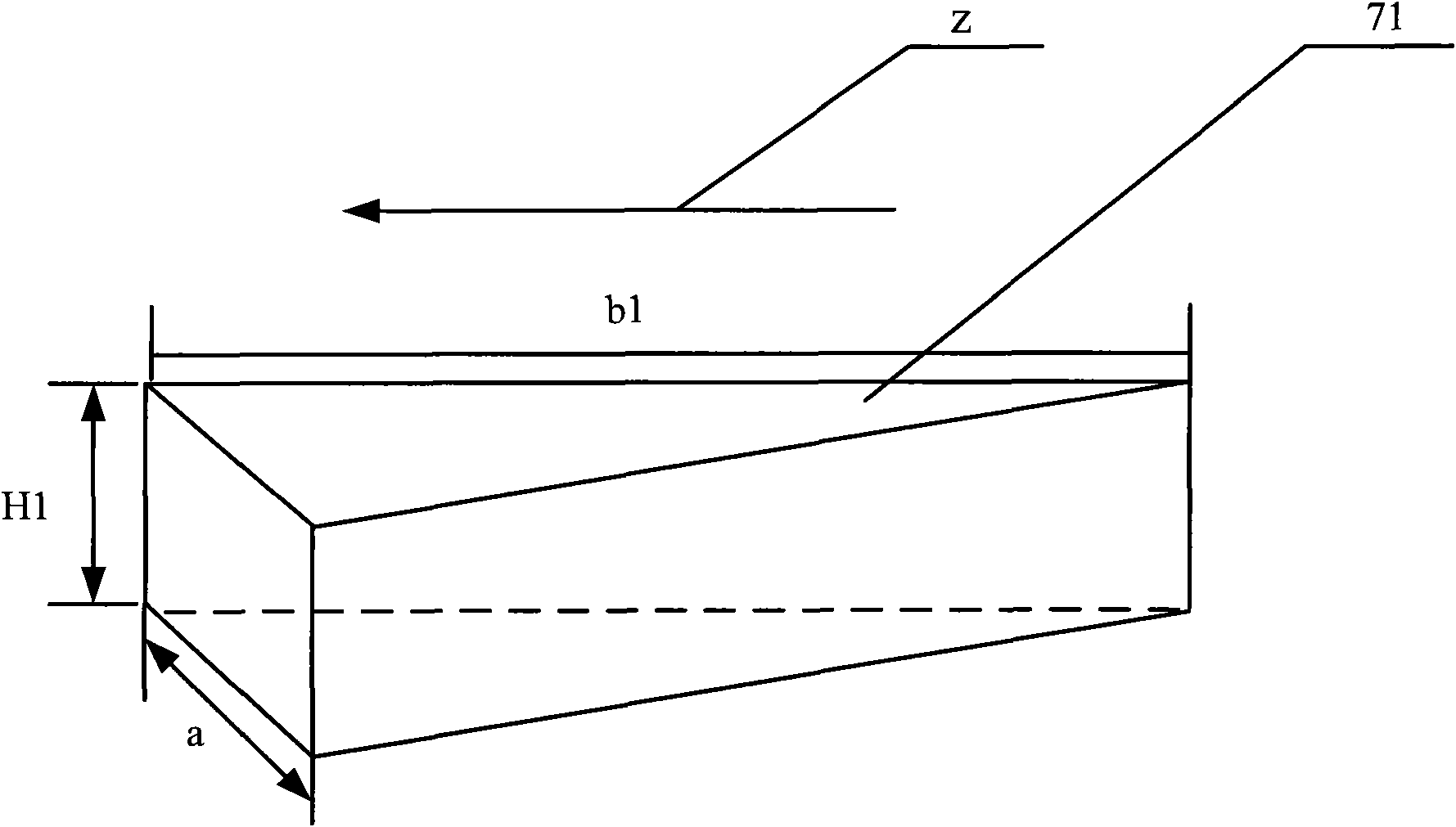

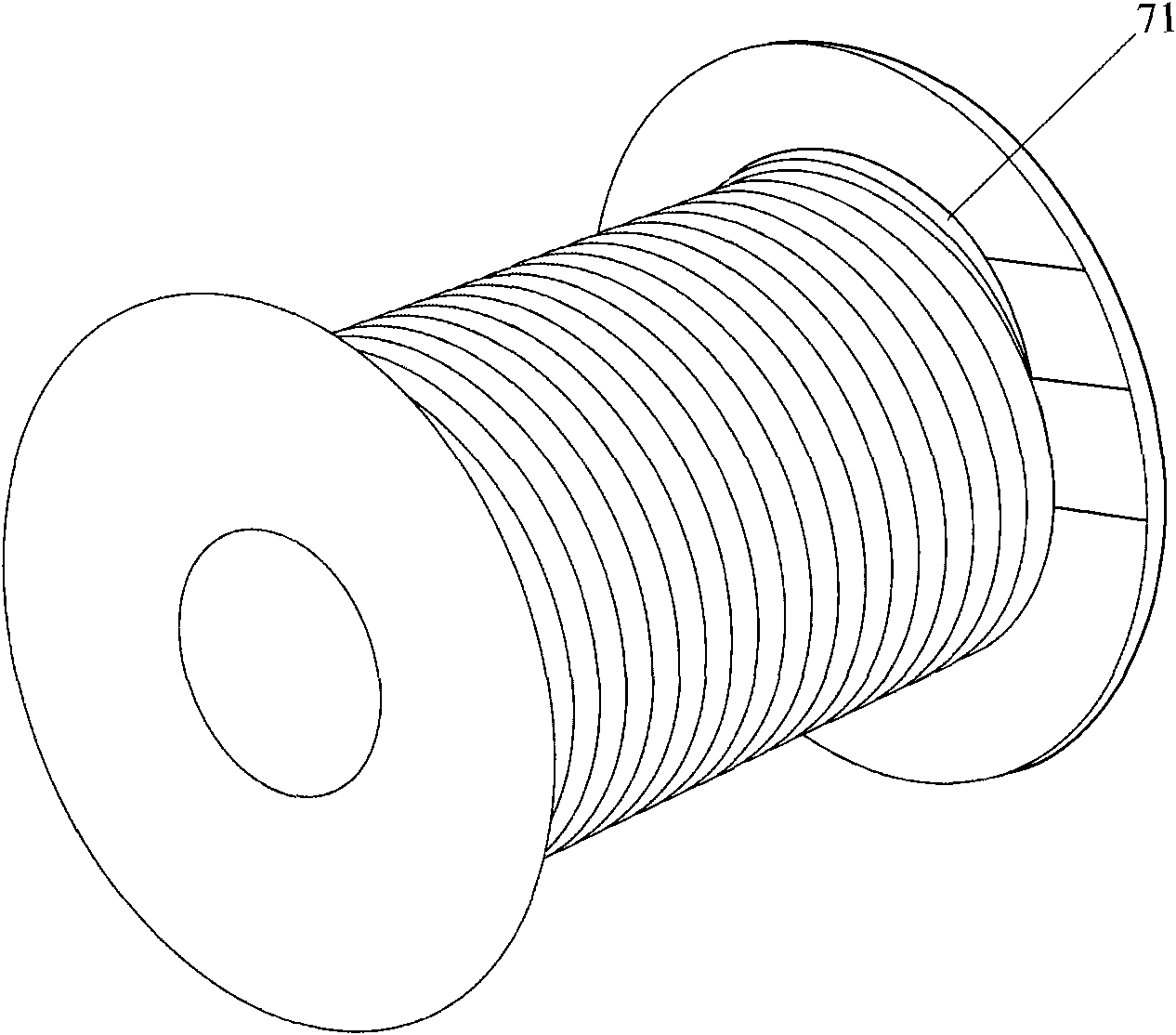

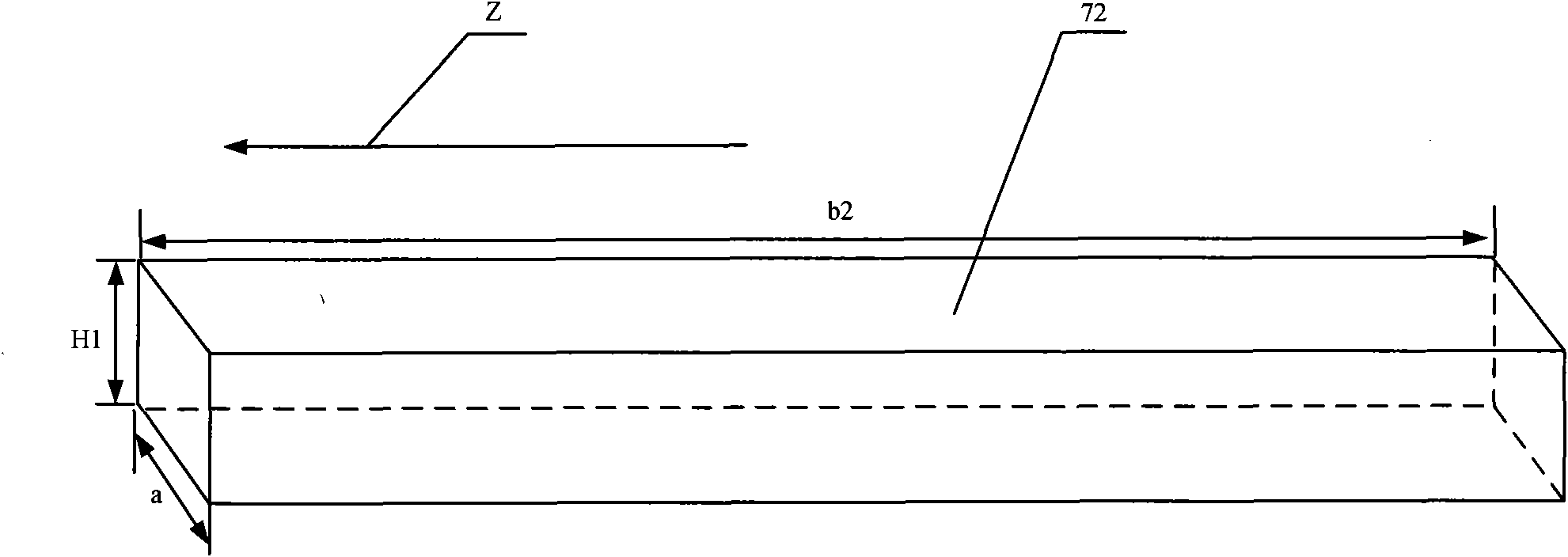

[0037] The main idea of the present invention is to set the boss on the side of the rope outlet of the reel into a three-section structure, and guide the steel wire rope from the first section of the rope outlet boss to adapt to the first oblique rope groove and advance half a step in the axial direction. Afterwards, the guide wire rope of the second section of the rope outlet boss adapts to the first straight line groove, and continues to wind; after that, the guide wire rope of the third section of the rope outlet boss adapts to the second oblique rope groove and Axially advance another half pitch. In this way, the steel wire rope is stably wound on the first layer of the broken line groove.

[0038] The present invention also sets the boss on the side of the non-rope outlet that cooperates with the boss on the side of the rope outlet. Three layers up to the next multi-layer.

[0039] The present invention is suitable for the winding of steel wire ropes with more than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com