Automatic coil winding system for motor production

An automatic winding and coil technology, which is applied in the direction of electric components, manufacturing motor generators, electrical components, etc., can solve the problems of affecting the winding quality and production efficiency of the motor, affecting the winding of the motor coil, and the confusion of coil winding and unwinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

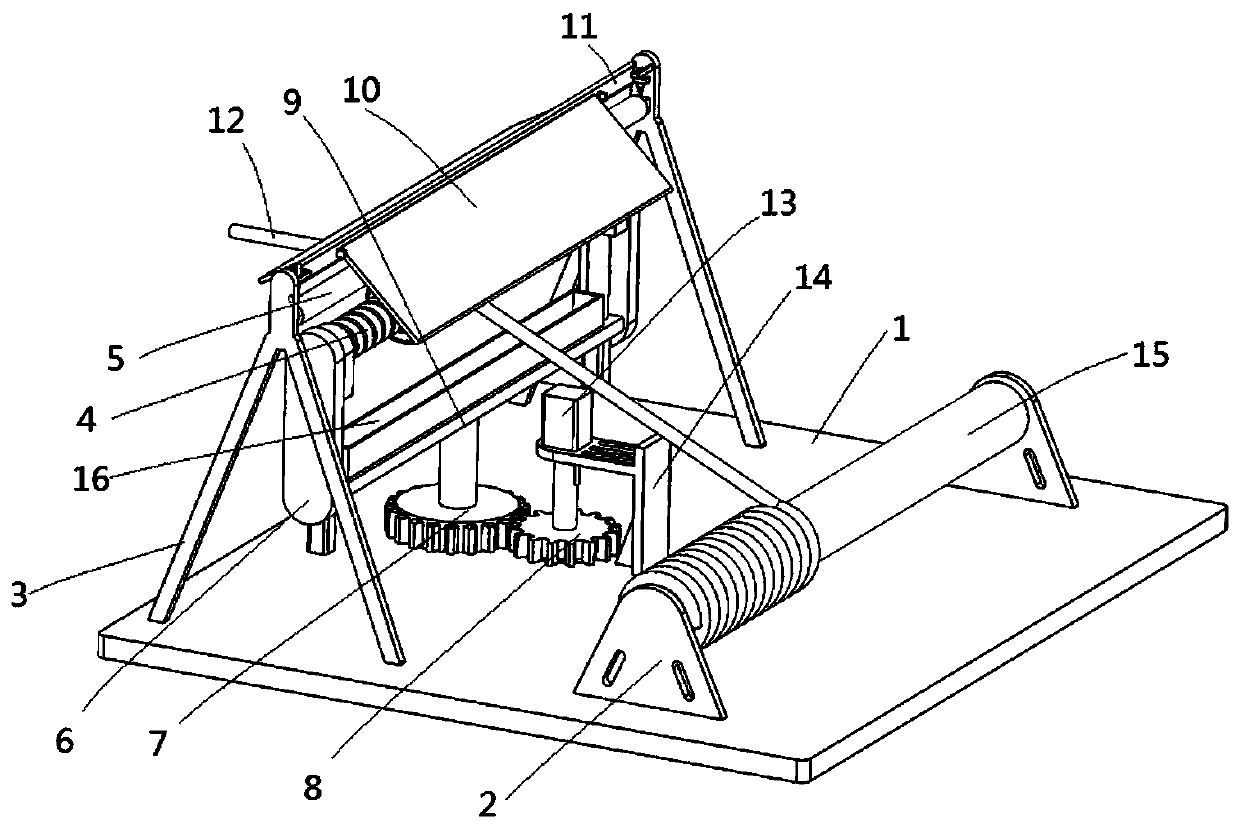

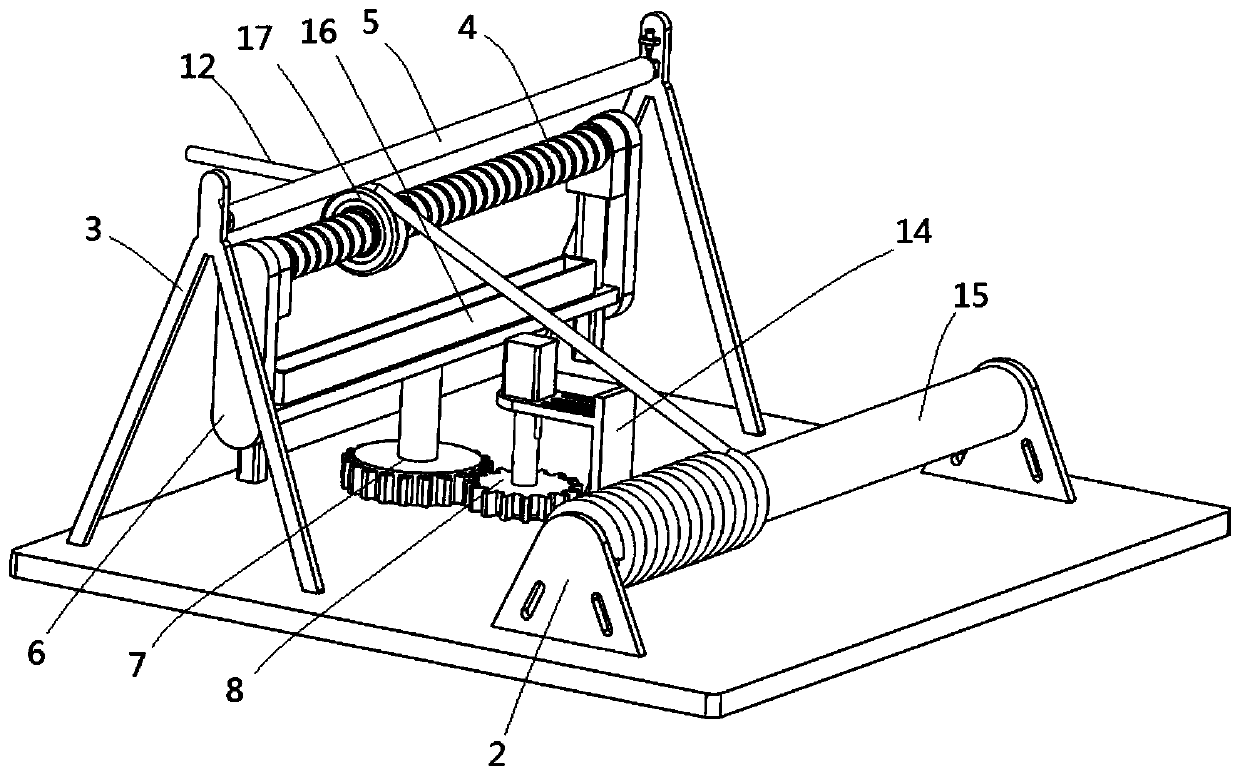

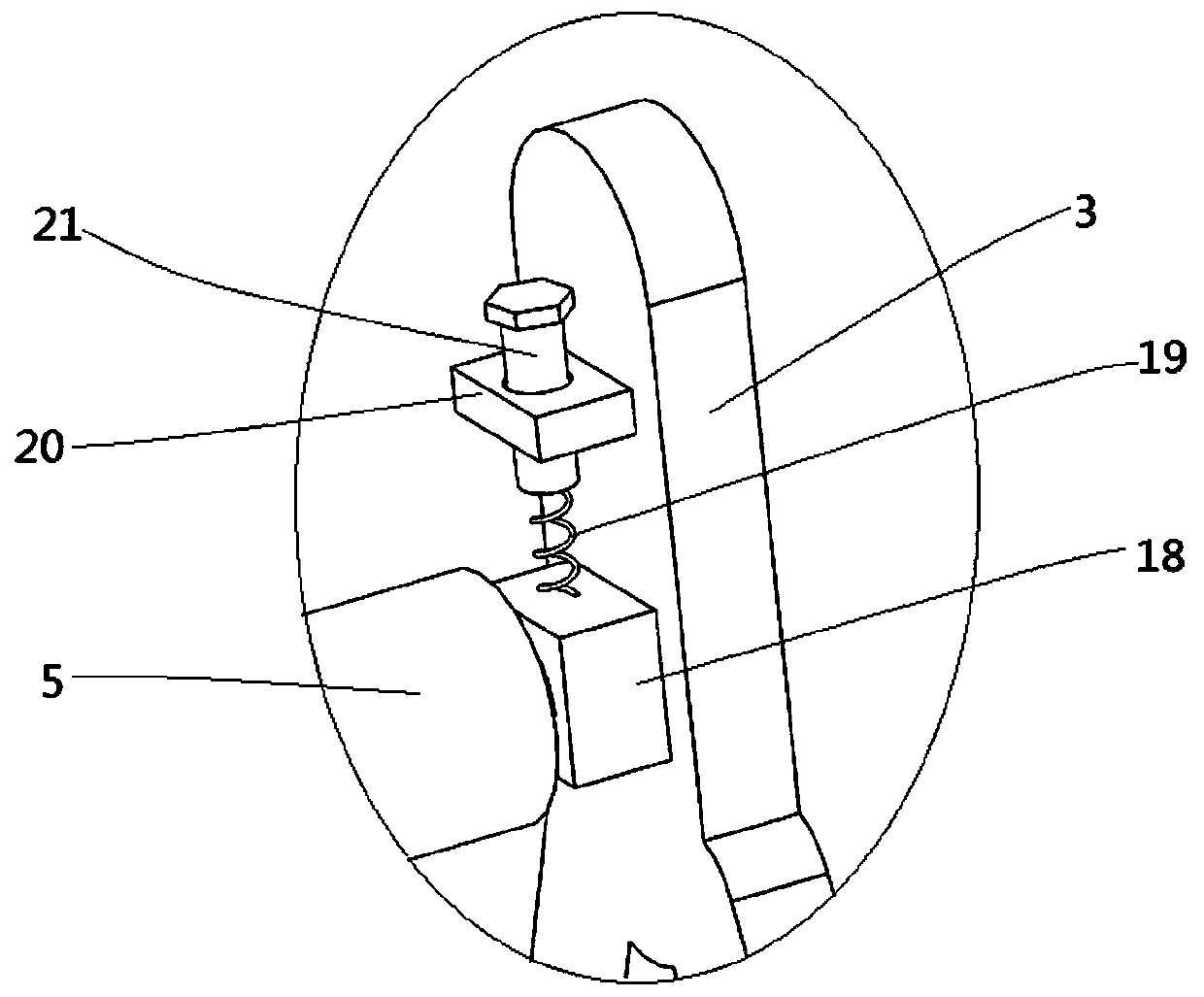

[0029] see Figure 1-5 , an automatic coil winding system for motor production, including a base plate 1, a winding drive mechanism installed on the base plate 1, a winding guide mechanism and a pressing mechanism, and the winding guide mechanism includes a rotating coil mounted on the top surface of the base plate 1 The turntable 7, the power mechanism for driving the turntable 7 to rotate, the horizontal plate 9 above the turntable 7, the side plates 6 fixed at the two ends of the two horizontal plates 9, the guides fixed between the two side plates 6 The rod 4 and the guide plate 17 that is movably sleeved with the guide rod 4.

[0030] Wherein, the top of the rotating disk 7 is connected to the horizontal plate 9 by a longitudinal rotating shaft, the annular inner wall of the guide disc 17 is provided with an internal thread, the outer wall of the guide rod 4 is provided with an external thread, the guide disc 17 is spirally connected with the guide rod 4, and the guide di...

Embodiment 2

[0039] In this example, see figure 1 , Image 6 , on the basis of Embodiment 1, a moving seat 27 is longitudinally slidably connected to the inner sides of the two side plates 6, and the two ends of the guide rod 4 are respectively fixed on the two moving seats, and the bottoms of the two ends of the horizontal plate 9 Drivers 28 are installed, and the telescopic ends of the drivers 28 are used to drive the moving seat 27 to move longitudinally;

[0040]Also be fixed with the push rod 11 that is positioned at the top of pressure rod 5 between the top of two brackets 3, the opposite both sides of push rod 11 all are connected with baffle plate 10 by pin shaft rotation, the movable end of baffle plate 10 is used for The winding wires 12 on both sides of the guide disk 17 are pressed down, thereby increasing the contact area between the winding wire 12 and the wire groove 24 on the guide disk 17 and increasing the frictional force.

[0041] When the present invention is in use,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com