Ultra-wide garbage grinding and collecting device

A garbage crushing and collecting device technology, which is applied in road cleaning, construction, cleaning methods, etc., can solve problems such as loud noise, small working surface, and unclean road cleaning, so as to avoid power consumption, reduce noise and vibration, and reduce The effect of litter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

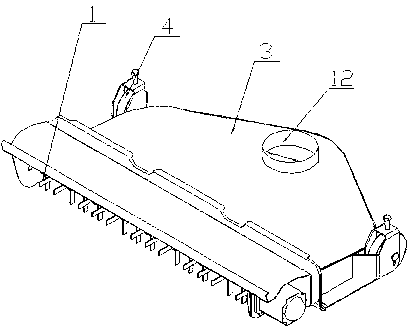

[0021] Example 1, an ultra-wide garbage crushing collection device, refer to figure 1 , The suction body 3 is provided with casters 4 and the rear part is provided with a suction port 12, and a garbage crushing device 1 for crushing relatively large garbage is installed at the front of the suction body 3. This constitutes a structure of the present invention.

Embodiment 2

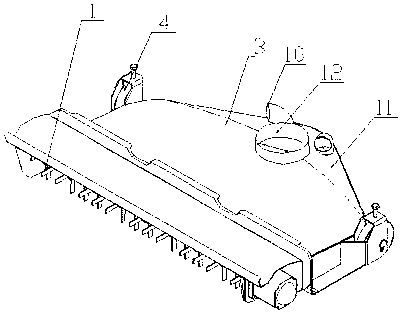

[0022] Example 2, an ultra-wide garbage crushing collection device, refer to figure 2 , Is on the basis of embodiment 1, after the suction port 12 of the suction body 3 is provided with a blowback chamber 11, the blowback chamber 11 is provided with a blowback port 10 communicating with an external dust suction fan, and the other is exactly the same as the first embodiment.

Embodiment 3

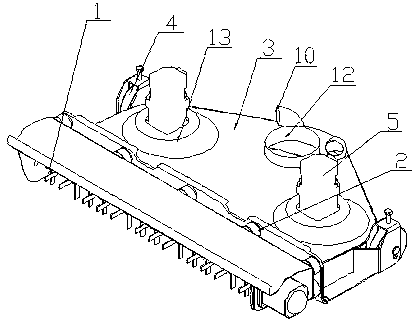

[0023] Embodiment 3, an ultra-wide garbage crushing collection device, refer to image 3 , Figure 4 , Is on the basis of embodiment 2, the front and left sides of the suction body 3 are symmetrically provided with cones 13, the suction sweeping brush 6 is installed on the sweeping motor 5 in the cone 13, the garbage crushing device 1 and the suction opening A shock-absorbing pad 2 is provided between the body 3, and the other parts are exactly the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com