Siphon type suction dredge

A dredge suction machine and siphon type technology, applied in the direction of the feeding/discharging device of the settling tank, etc., can solve the problems that the dredge nozzle cannot suck mud smoothly, the mud sucking effect is not good, and the working bridge resistance is large, so as to achieve the purpose of suction Good mud effect, reduced power and energy consumption, and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

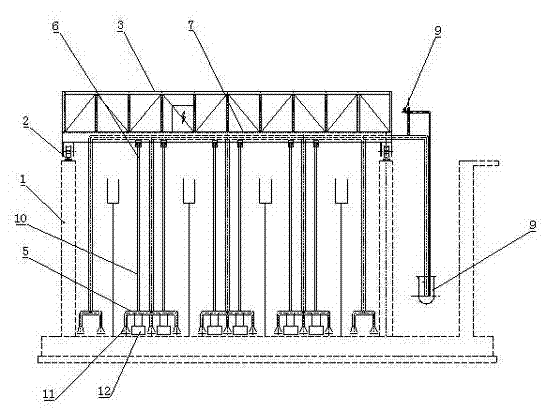

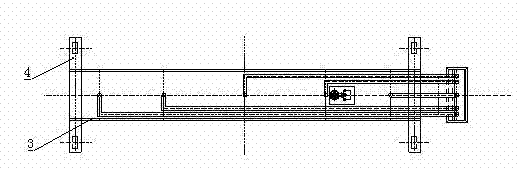

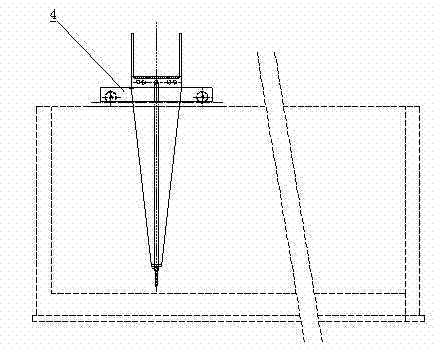

[0011] like figure 1 , 2 , 3, including sewage treatment tank 1, guide rail 2, working bridge 3, end beam 4, horizontal mud suction pipe 5, underwater mud suction pipe 6, water mud discharge pipe 7, water seal cylinder 8, vacuum pumping system 9, Hanger 10, suction nozzle 11, diamond-shaped mud scraper 12.

[0012] There are guide rails 2 on both sides of the pool top of the sewage treatment pool 1, and the installation structure between the guide rail 2 and the pool top is as follows: Figure 4 As shown, steel plates 11 are pre-embedded at certain intervals on the top of the pool, and the size of the pre-embedded steel plates 11 is 200*100*12mm. Two groups of bolt connection holes are drilled on the plate 21, the guide rail 2 is placed on the top surface of the pool, and the backing plate 21 is connected with a pressure plate 23 by bolts 22, and the inner end of the pressure plate 23 presses the bottom of the guide rail 2.

[0013] The working bridge 3 spans the two guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com