Wallboard cutting saw

A technology for cutting saws and wall panels, which is applied to stone processing tools, work accessories, manufacturing tools, etc., can solve the problems that the cutting accuracy and speed cannot meet the rapid design and installation of modular houses, and achieve the purpose of increasing the effective suction area, Wide range of applications and the effect of reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

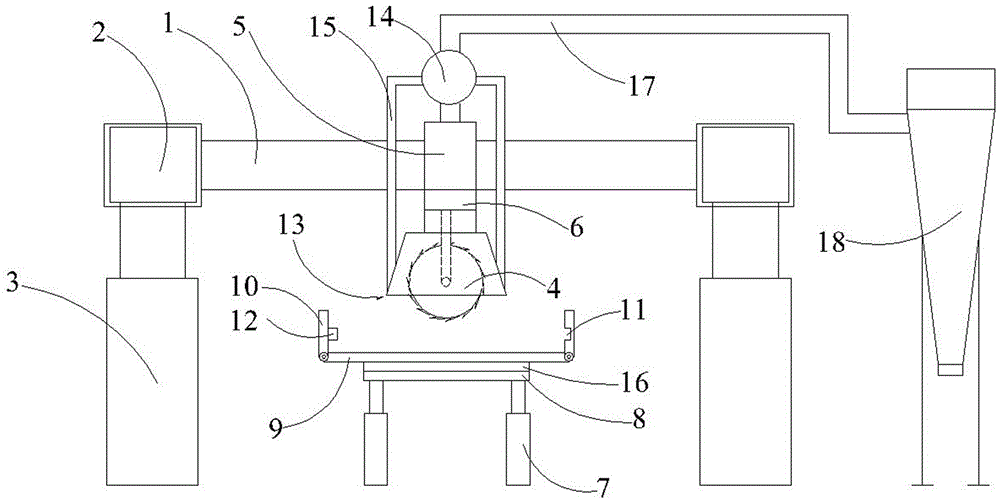

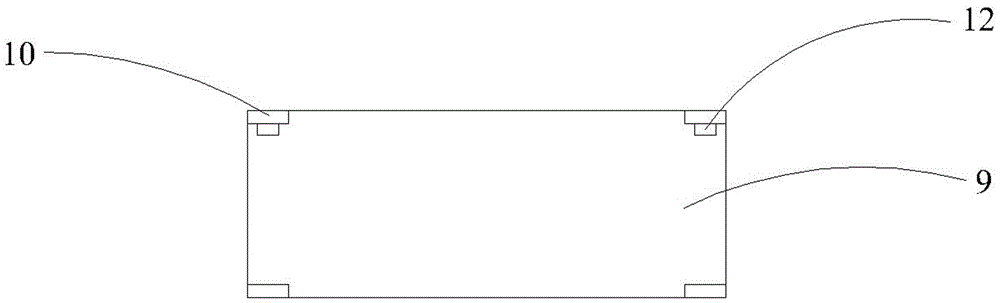

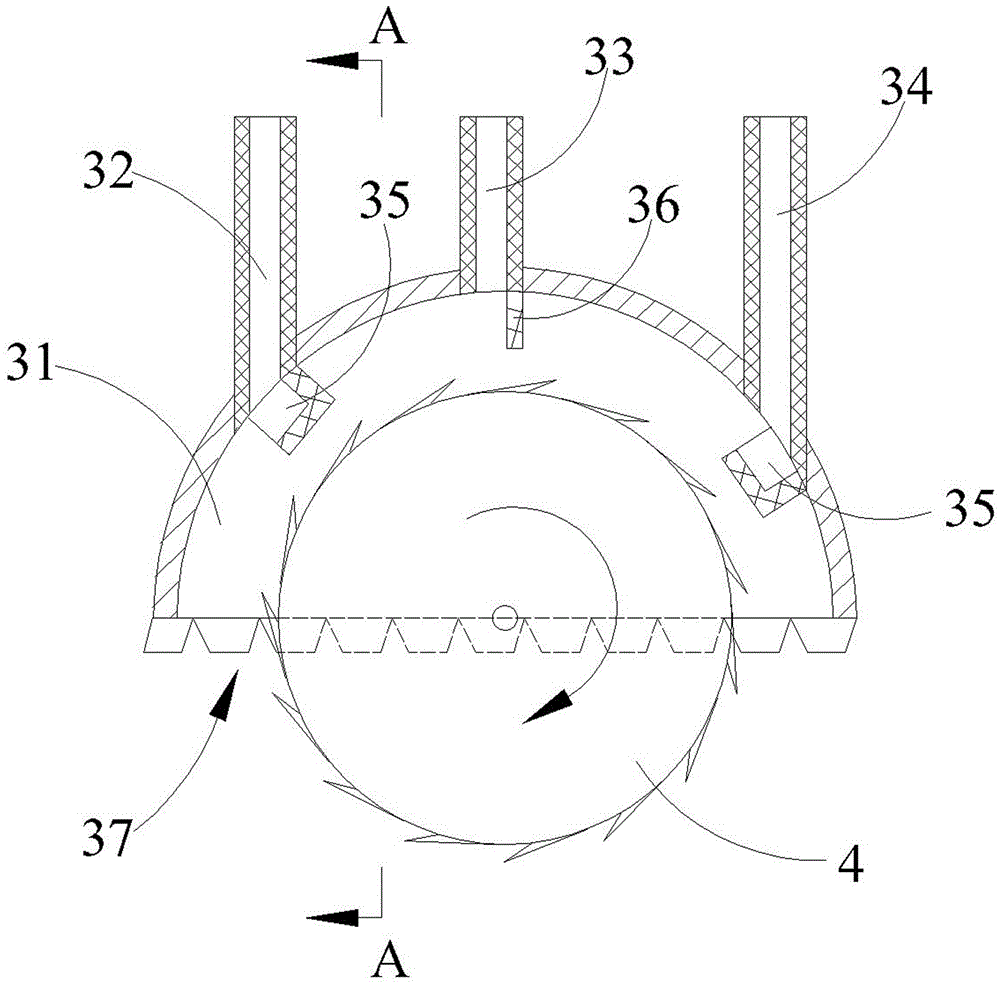

[0024] combine Figure 1~4 As shown, a wallboard cutting saw, which includes a bracket, a cutting device, a dust removal device, and a wallboard fixing table; 2. The column 3 at the bottom; the two slide rails 2 are parallel to each other and the cross rail 1 can move along the slide rail 2; the cutting device includes a base 5, a saw blade 4 and a motor 6 that drives the saw blade 4 to rotate. The base 5 is nested on the cross rail 1, and the motor 6 is fixedly connected to the base 5; the wall plate fixing table includes a hydraulic rod 7, a support plate 8, a turntable bearing 16 and a fixed plate 9; the hydraulic rod 7 is four and are respectively hinged with the four vertices at the bottom of the support plate 8; the support plate 8 and the fixed plate 9 are connected by a turntable bearing 16; the dust removal device includes a dust collection cover 13 arranged above the saw blade 4 , suction fan 14, cyclone separator 18 and the air duct 15 connecting the suction hood 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com