Non-cutting energy obtaining method for main transmission system of numerically controlled lathe

A main drive system and CNC lathe technology, applied to metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve the lack of methods to obtain non-cutting energy consumption of the main drive system of machine tools, and the complex law of non-cutting power changes And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

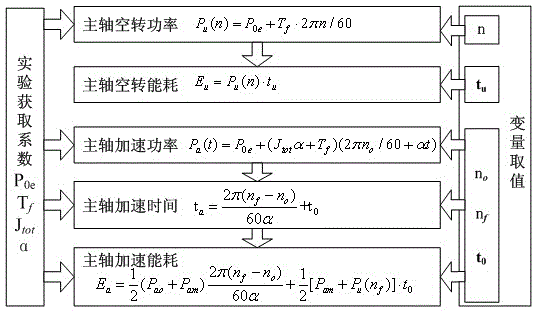

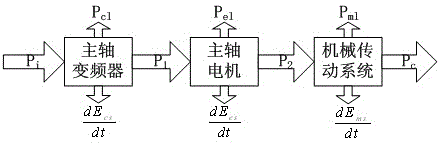

Method used

Image

Examples

Embodiment

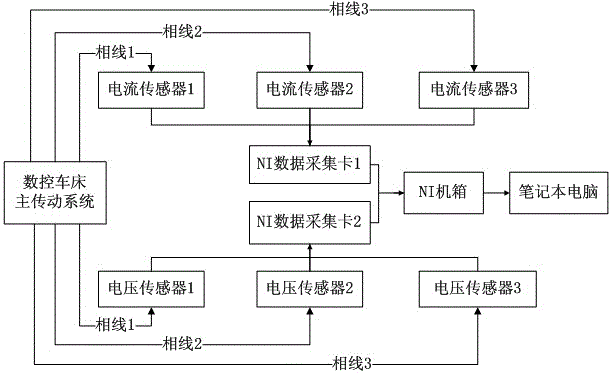

[0092] The CNC lathe CK6153i of Jinan No. 1 Machine Tool Factory is selected as the research object, and the method of the present invention is used to obtain the non-cutting energy consumption of its main drive system. The process is as follows:

[0093] 1. Connect the power acquisition experimental device to the power input terminal of the main drive system of the CNC lathe. The sampling frequency of the voltage and current is f=1000Hz, and the average value of the power data is filtered at an interval of N=100, then f 1 =f / N=10Hz, Δt=1 / f 1 =0.1s, that is, output and store 10 power data per second. The speed range of CNC lathe CK6153i is 200~2000rpm, within this range, take n i =250rpm, 500rpm, 750rpm, 1000rpm, 1250rpm, 1500rpm, 1750rpm, make the spindle start to n i , at speed n i Idle at a constant speed for a period of time, and finally stop, collect the power data input to the spindle system in real time, and get 7 sets of data in total.

[0094] 2. Corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com