Capacitive touch screen and manufacturing method thereof

A technology of capacitive touch screen and manufacturing method, which is applied to the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problems of inability to use plastic substrates, poor high temperature resistance, and difficulty in reducing the cost of capacitive touch screens. Guaranteed conductivity and light transmittance, reduced manufacturing cost, high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

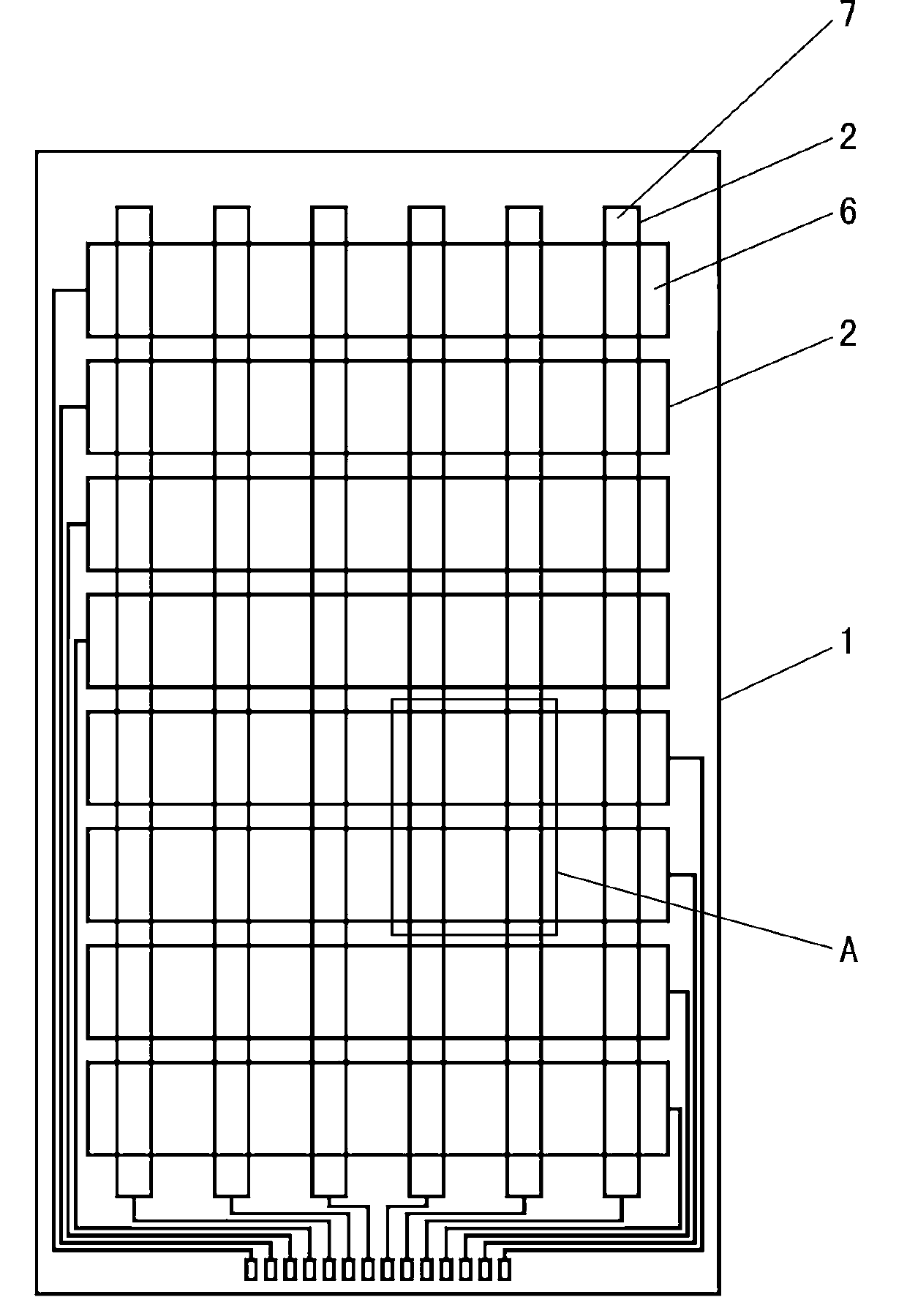

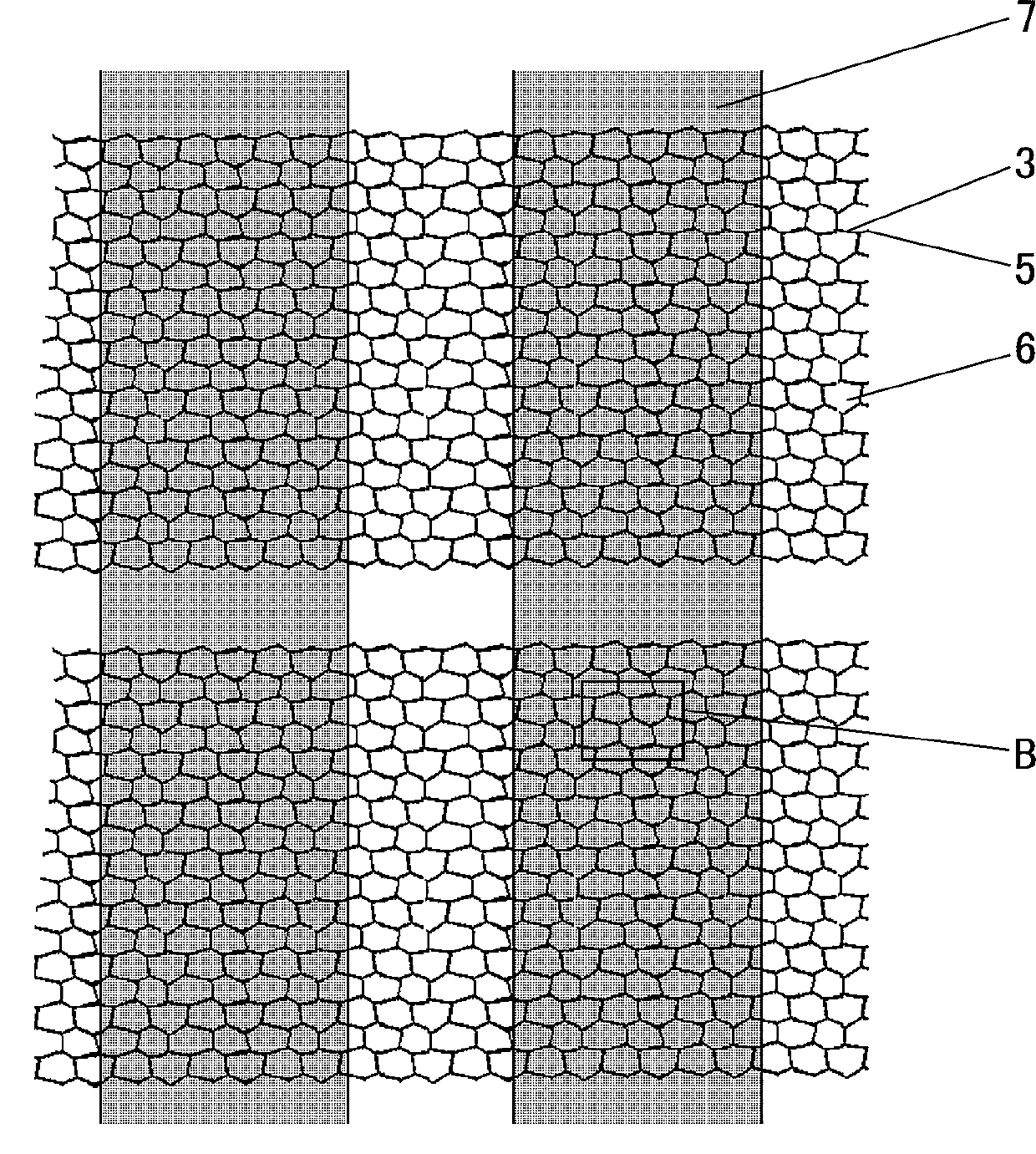

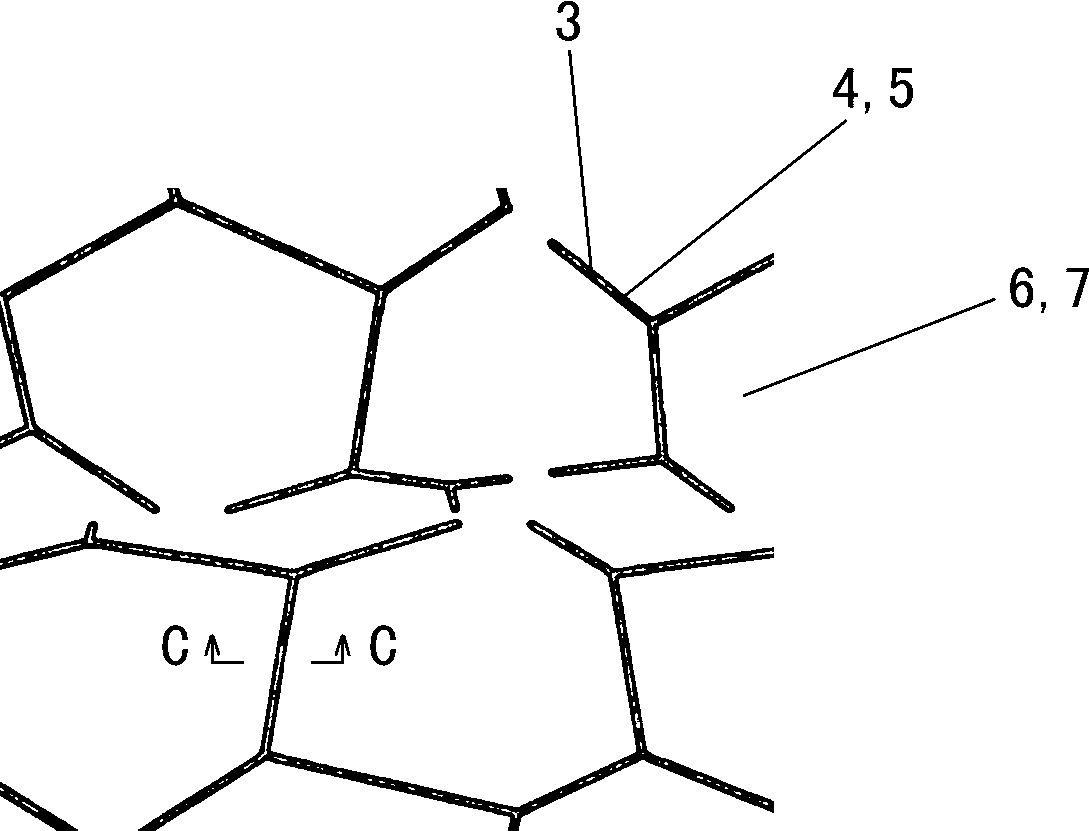

[0051] Such as Figure 1-Figure 4 As shown, this capacitive touch screen includes a glass substrate 1, an electrode layout area 2 is provided on both surfaces of the glass substrate 1, and a plurality of grooves 3 are arranged on the electrode layout area, and the grooves 3 are filled with paste of conductive nanoparticles. body 4 (such as nano-carbon particles, nano-gold and silver particles, etc.), the paste 4 of conductive nanoparticles in each groove 3 is connected to each other to form conductive thin wires 5, which are formed by mesh-like tiling For the sensing electrodes of the capacitive touch screen, a first sensing electrode 6 is formed on one surface of the glass substrate 1 , and a second sensing electrode 7 is formed on the other surface of the glass substrate 1 .

[0052] Taking the first electrode as an example, such as Figure 5 a- Figure 5 As shown in g, its manufacturing method comprises the steps:

[0053] 1), such as Figure 5 As shown in a, a layer of...

Embodiment 2

[0061] Such as Figure 6-Figure 8 As shown, the structure of an integrated capacitive touch screen is adopted, the substrate is a plastic substrate 11, and the sensing electrodes are made on the back of the plastic substrate 11, and the plastic substrate 11 also serves as a protective plate, and the electrode layout area 12 is set on the plastic substrate. On the back side of 11, the sensing electrodes adopt a complementary triangular design, and a plurality of grooves 13 are arranged on the electrode layout area 12, (refer to image 3 , Figure 4 ) The grooves 13 are filled with paste 4 of conductive nanoparticles (such as nano-carbon particles, nano-gold and silver particles, connections of nano-carbon particles, etc.), and the paste 4 of conductive nanoparticles in each groove 13 is connected to each other The conductive thin wires 5 are formed, and the conductive thin wires 5 form the sensing electrodes of the capacitive touch screen by means of grid-like tiling, and the ...

Embodiment 3

[0067] Under the situation that other parts are all identical with embodiment two, its difference is: as Figure 11 , Figure 12 As shown, a plurality of first electrode arrangement regions 31 extending in the same direction are provided on one surface of the plastic substrate 11, and a second electrode arrangement region 32 arranged on one side of each first electrode arrangement region 31, the first electrodes The layout area 31 and the second electrode layout area 32 are all provided with a plurality of grooves 33. After the paste 4 of conductive nanoparticles is filled in the grooves 33, the conductive nanoparticles in the grooves 33 on each first electrode layout area 31 The paste 4 constitutes the first sensing electrode 34 , and the paste 4 of conductive nanoparticles in the grooves 33 on each second electrode arrangement area 32 constitutes the second sensing electrode 35 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com