Preparation method of magnetic nano porous Fe-Pt alloy with electro-oxidation catalytic performance

An electro-oxidation catalysis, magnetic nanotechnology, applied in nanotechnology and other directions, can solve the problems of cumbersome dealloying process, strict requirements for thin-film alloy preparation process, brittleness, etc., to improve the controllability of pore size and good resistance to CO. Poisoning ability, the effect of improving the uniformity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: now with Fe 60 Pt 10 B 30 Taking the amorphous precursor alloy as an example, the implementation of the preparation and performance testing of the Fe-Pt nanoporous alloy will be described in detail in conjunction with the accompanying drawings.

[0021] Step 1: Preparation of Amorphous Precursor Alloy Strips

[0022] 1.1 Select high-purity Fe (99.9wt.%), Pt (99.95wt.%) and B (99.5wt.%) raw materials according to Fe 60 Pt 10 B 30 (atomic percent) ingredients are weighed for batching.

[0023] 1.2 Alloy ingot melting

[0024] Mix the weighed metal raw materials into the water-cooled copper crucible of the arc melting furnace, and evacuate to 6×10 -3 Pa, and then filled with an appropriate amount of argon to start melting the alloy. After melting, the alloy ingot was turned upside down and smelted repeatedly 4 times to obtain Fe with uniform composition. 60 Pt 10 B 30 alloy ingot.

[0025] 1.3 Preparation of amorphous strips

[0026] Put the alloy...

Embodiment 2

[0041] Example 2: Precursor alloy composition Fe 60 Pt 10 B 25 Si 5

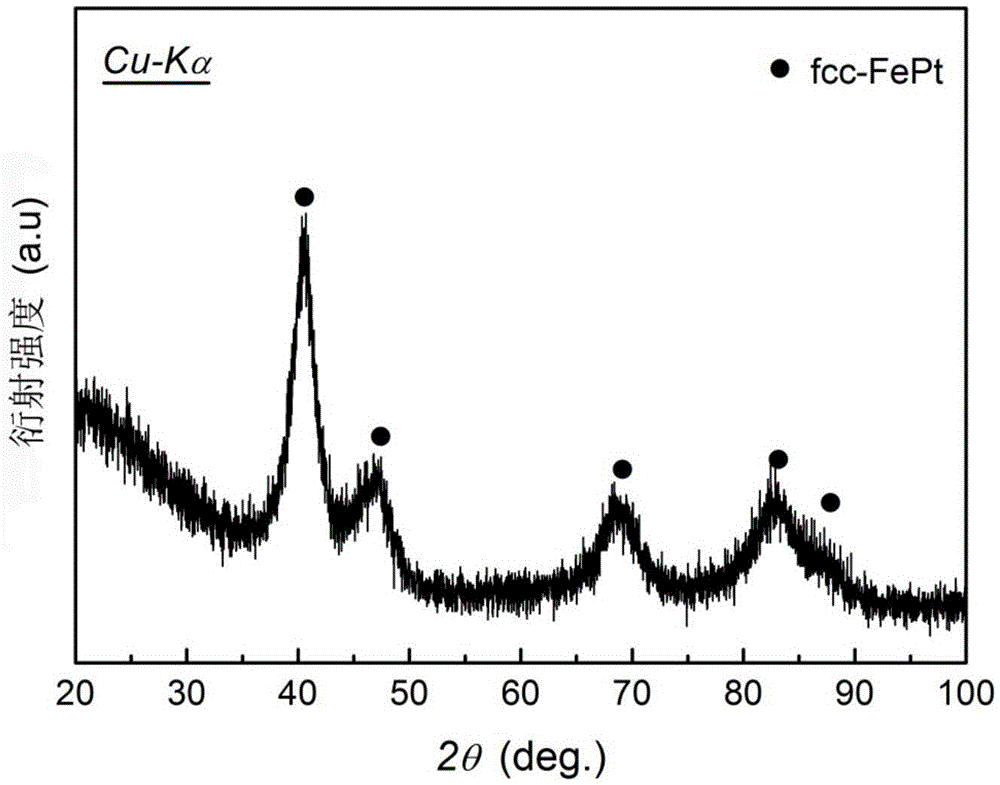

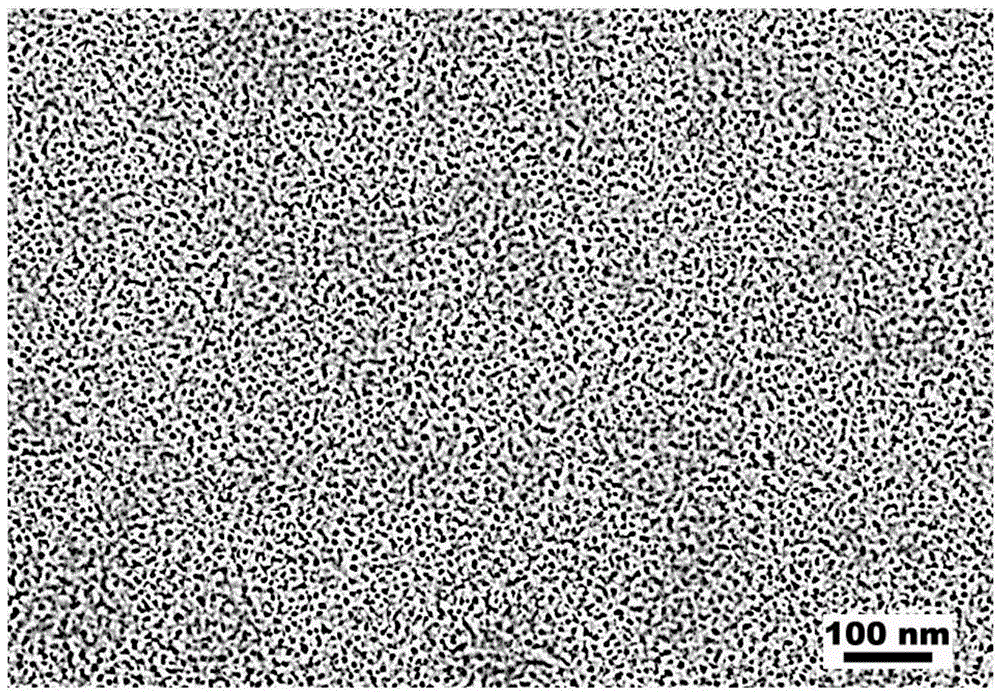

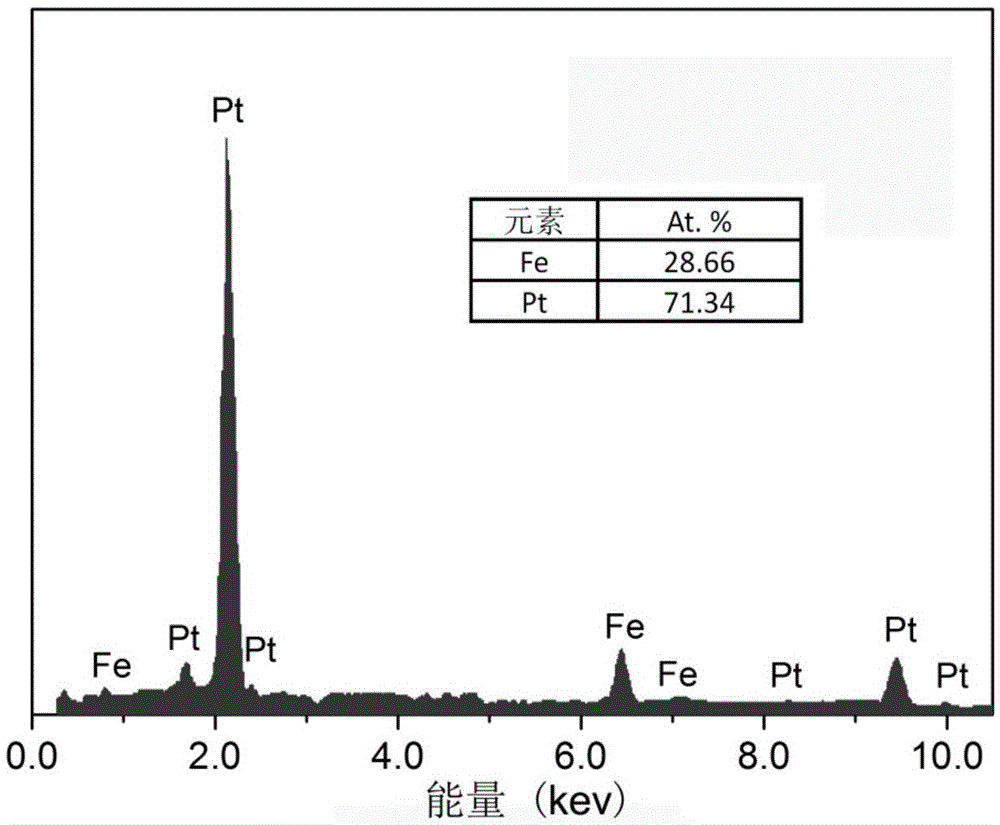

[0042] The preparation of the precursor alloy and the nanoporous alloy, as well as the magnetic and catalytic performance tests are the same as in Example 1. In the first step, the width of the precursor alloy strip is about 1-2 mm, the thickness is about 20 μm, and it is a completely amorphous structure. The dealloying voltage involved in the second step 2.2 is -190 mV, and the obtained nanometer The porous Fe-Pt alloy is mainly composed of fcc-FePt phase, and the pore size and pore wall thickness are about 6nm and 10nm, respectively. The data obtained in the magnetic and catalytic performance test of the third step are: M s 23.5emu / g at 0.856V f 1.047A / cm 2 , J at 0.419V b 0.533A / cm 2 , J f / J b is 1.964. The specific data are listed in the attached table.

Embodiment 3

[0043] Embodiment 3: Precursor alloy composition Fe 60 Pt 5 PD 5 B 30

[0044] The preparation of the precursor alloy and the nanoporous alloy, as well as the magnetic and catalytic performance tests are the same as in Example 1. The precursor alloy strip obtained in the first step has a width of about 1-2 mm, a thickness of about 20 μm, and a completely amorphous structure. The dealloying voltage involved in the second step 2.2 is -190 mV, and the obtained The nanoporous Fe-Pt alloy is mainly composed of fcc-FePt phase, and the pore size and pore wall thickness are about 7nm and 10nm, respectively. The data obtained in the magnetic and catalytic performance test of the third step are: M s 21.4emu / g, J at 0.821V f 0.484A / cm 2 , J at 0.456V b 0.204A / cm 2 , J f / J b is 2.373. The specific data are listed in the attached table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com