Nano-porous Pd material with electrooxidation catalytic performances and preparation method

An electro-oxidative catalysis and nano-porous technology, applied in the field of new materials, can solve the problems of easy pore size coarsening, precious metal recovery, brittleness, etc., and achieve uniform and controllable pore size, simple preparation process, and good structural integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

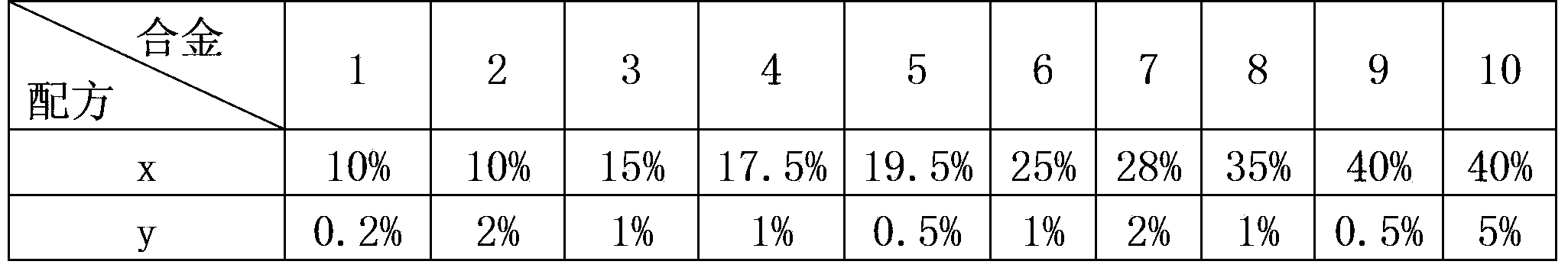

[0041] Example 1Co 0.80 PD 0.195 sn 0.005 alloy

[0042] Step 1: Component weighing and alloy ingot melting

[0043] Will Co 0.80 PD 0.195 sn 0.005 The atomic percent composition of the alloy is converted to a weight percent composition:

[0044] High-purity components are used, and ingredients are made according to the alloy composition; the weighed metal raw materials are mixed and placed in a water-cooled copper crucible of a non-consumable arc melting furnace, and smelted under the protection of high-purity argon, and then the alloy ingot is put up and down Flip, so repeated smelting 3 times, to obtain alloy ingots with uniform composition;

[0045] Step 2: Preparation of broadband samples

[0046] The alloy ingot is crushed and put into a quartz tube. The size of the nozzle of the quartz tube is: length 8mm×width 1mm. Put the charged quartz tube in the induction heating coil, use the vacuum copper roll stripping technology, under the protection of high-purity arg...

Embodiment 2

[0056] Example 2Co 0.70 PD 0.28 sn 0.02 alloy

[0057] Step 1: Component weighing and alloy ingot melting

[0058] Same as Step 1 in Example 1.

[0059] Step 2: Preparation of broadband samples

[0060] Same as Step 2 in Example 1.

[0061] Step 3: Microstructure analysis of the precursor alloy

[0062] With step 3 in embodiment 1, the result shows that Co 0.70 PD 0.28 sn 0.02 The broad band of the alloy is a nearly single FCC type solid solution structure, the grain size is about 0.5-3 μm, and there are a small amount of Sn-rich precipitates on the grain boundary and the surface of the matrix.

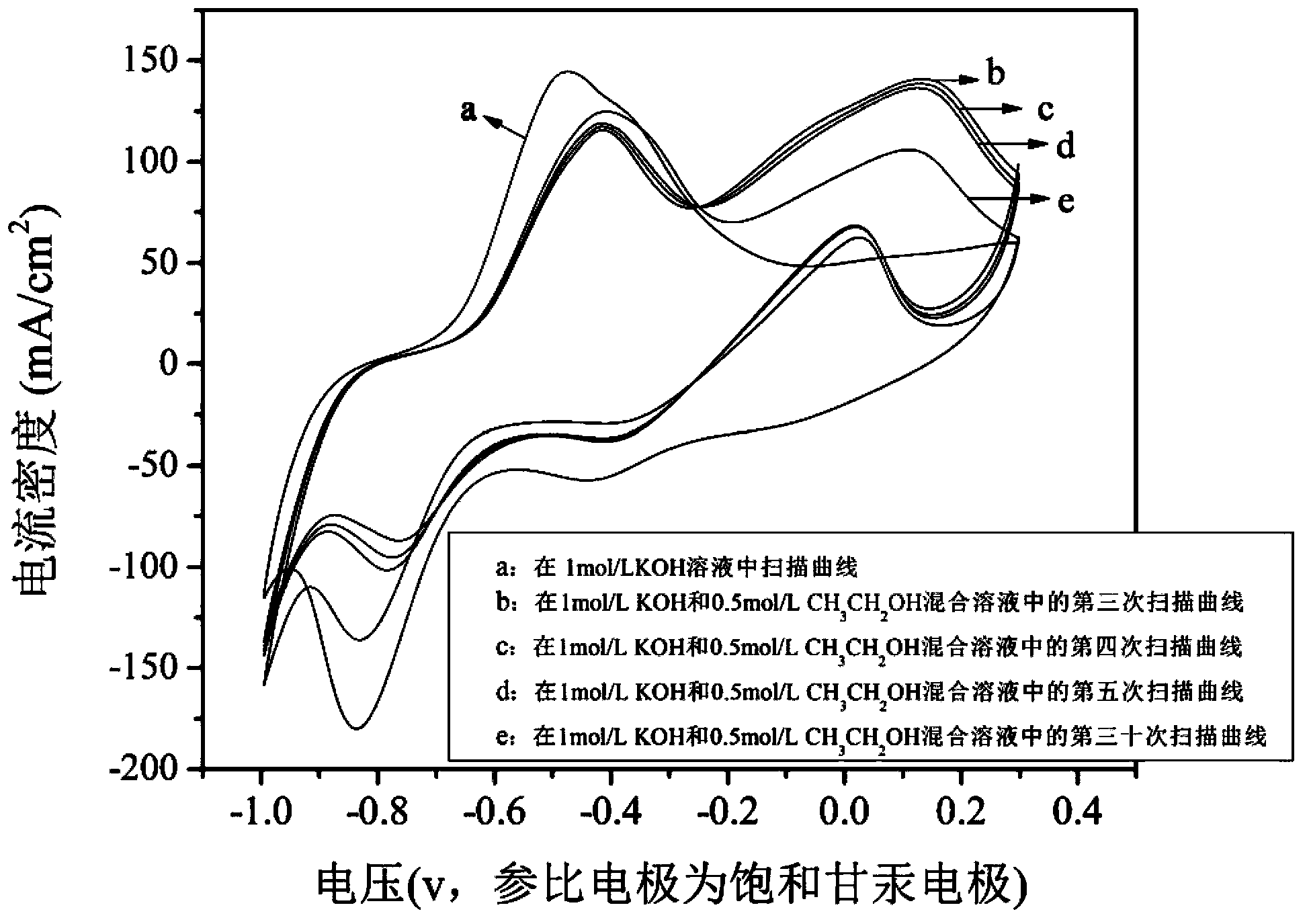

[0063] Step 4: Electrochemical performance test and dealloying test

[0064] Same as Step 4 in Example 1, the measured critical potential is about 0.3V. Porous materials with good integrity can be obtained by constant voltage dealloying in the range of 0.35-0.45V.

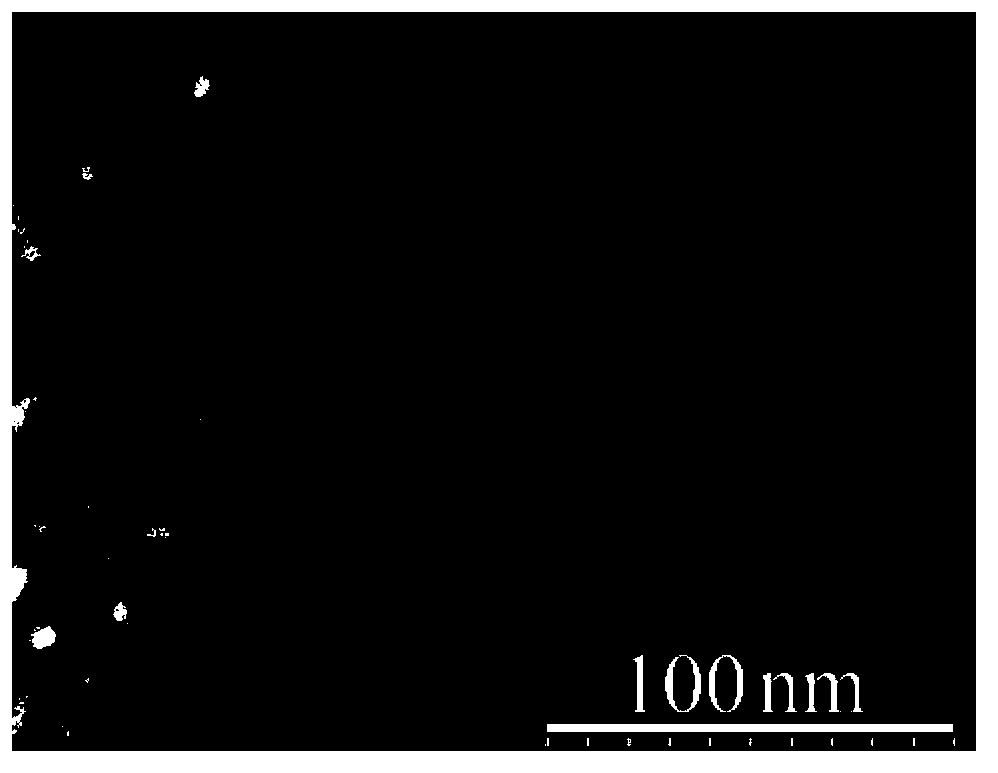

[0065] Step 5: Structure Characterization and Component Testing of Nanoporous Materials

[0066]Same as Ste...

Embodiment 3

[0069] Example 3Co 0.64 PD 0.35 sn 0.01 alloy

[0070] Step 1: Component weighing and alloy ingot melting

[0071] Same as Step 1 in Example 1.

[0072] Step 2: Preparation of broadband samples

[0073] Same as Step 2 in Example 1.

[0074] Step 3: Microstructure analysis of the precursor alloy

[0075] With step 3 in embodiment 1, the result shows that Co 0.64 PD 0.35 sn 0.01 The broad band of the alloy is a nearly single FCC type solid solution structure, the grain size is about 0.5-3 μm, and there are a small amount of Sn-rich precipitates on the grain boundary and the surface of the matrix.

[0076] Step 4: Electrochemical performance test and dealloying test

[0077] Same as Step 4 in Example 1, the measured critical potential is about 0.42V. Porous materials with good integrity can be obtained by constant voltage dealloying in the range of 0.45-0.55V.

[0078] Step 5: Structure Characterization and Component Testing of Nanoporous Materials

[0079] Same as S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com