Smell removing master batch as well as preparation method and application thereof

A masterbatch and pelletizing technology, applied in the field of polymers, can solve the problems of poor VOC deodorization effect and foreign substance pollution, etc., and achieve obvious effects of VOC and odor removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

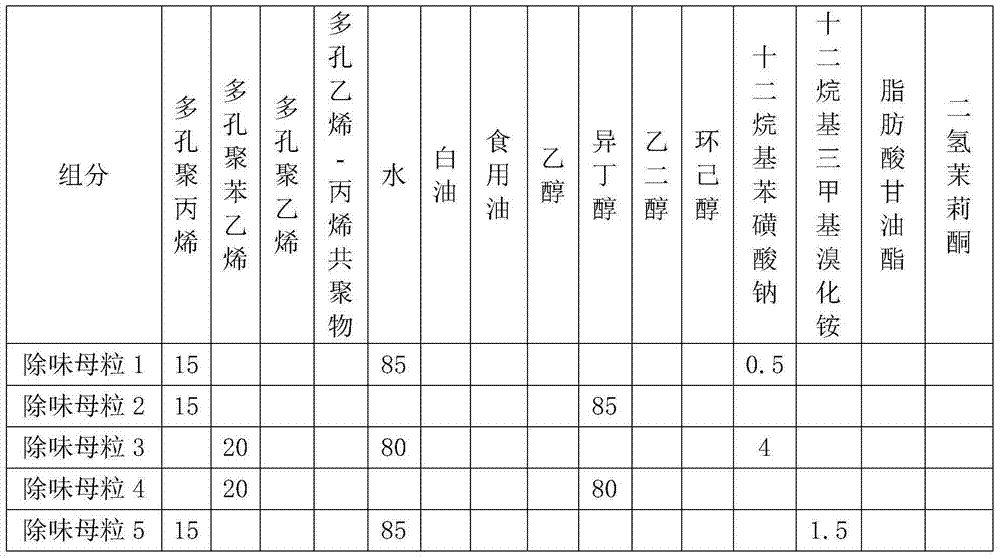

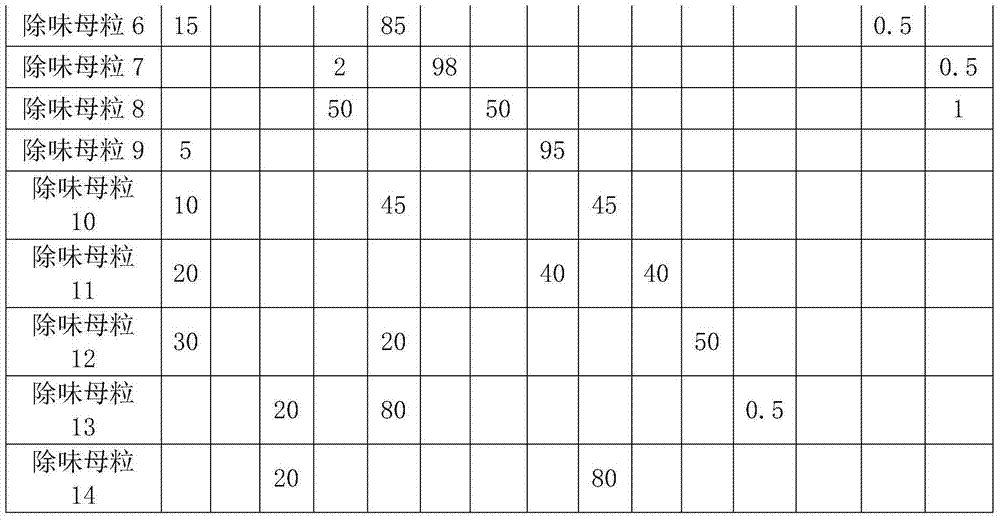

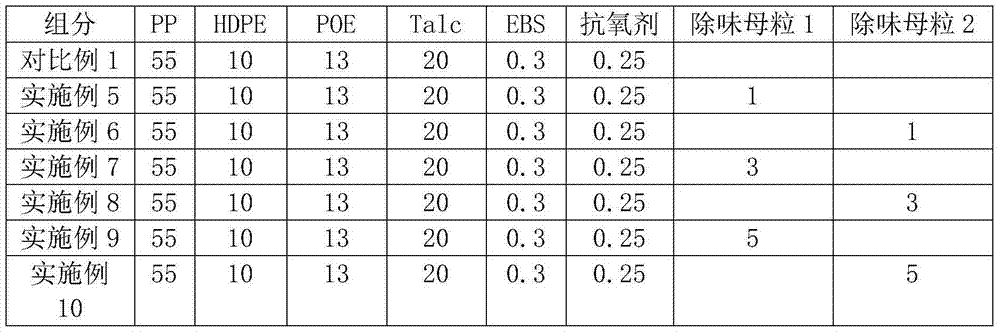

Examples

Embodiment 1

[0045] 80 parts of polypropylene, supercritical CO 2 After mixing 0.5 parts and 5 parts of calcium carbonate, porous polypropylene beads are prepared by physical extrusion, foaming and pelletizing;

Embodiment 2

[0046]Embodiment 2: 99.5 parts of polyethylene, supercritical N 2 After 10 parts, sodium bicarbonate and citric acid mixture 0.5 are mixed, the porous polyethylene beads are prepared by the still pressure foaming method;

Embodiment 3

[0047] Example 3: After mixing 85 parts of polystyrene, 5 parts of alkane foaming agent, 1 part of talcum powder and 2 parts of kaolin, porous polystyrene beads were prepared by physical extrusion foaming and pelletizing method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com