Use of Manganese Oxide and Activated Carbon Fibers for Removing a Particle, Volatile Organic Compound or Ozone from a Gas

a technology of activated carbon fiber and manganese oxide, which is applied in the direction of catalyst activation/preparation, metal/metal-oxide/metal-hydroxide catalyst, etc., can solve the problems of not enough evidence to support the mvk mechanism and prior studies have failed to address the issue of successfully implementing this technology, so as to reduce the content and reduce the content of volatile organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

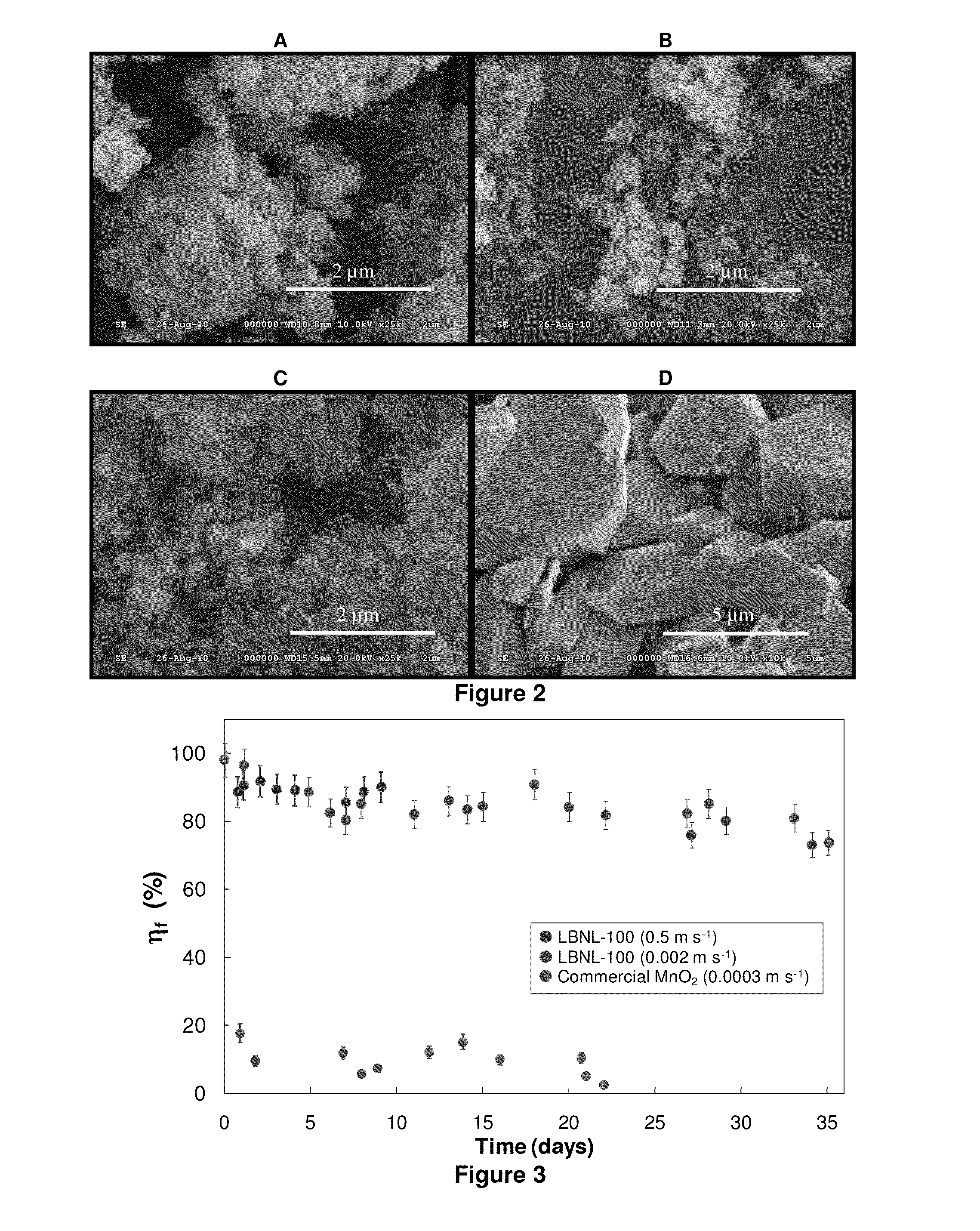

[0118]In this study, we synthesized novel MnOx catalysts (1<x<2), and evaluated experimentally the efficacy of filters coated with this material to oxidize formaldehyde with moderately low pressure drops. The results obtained in this study illustrate the potential of this approach as an effective indoor formaldehyde removal technology.

[0119]Preparation of Manganese Oxide Catalysts.

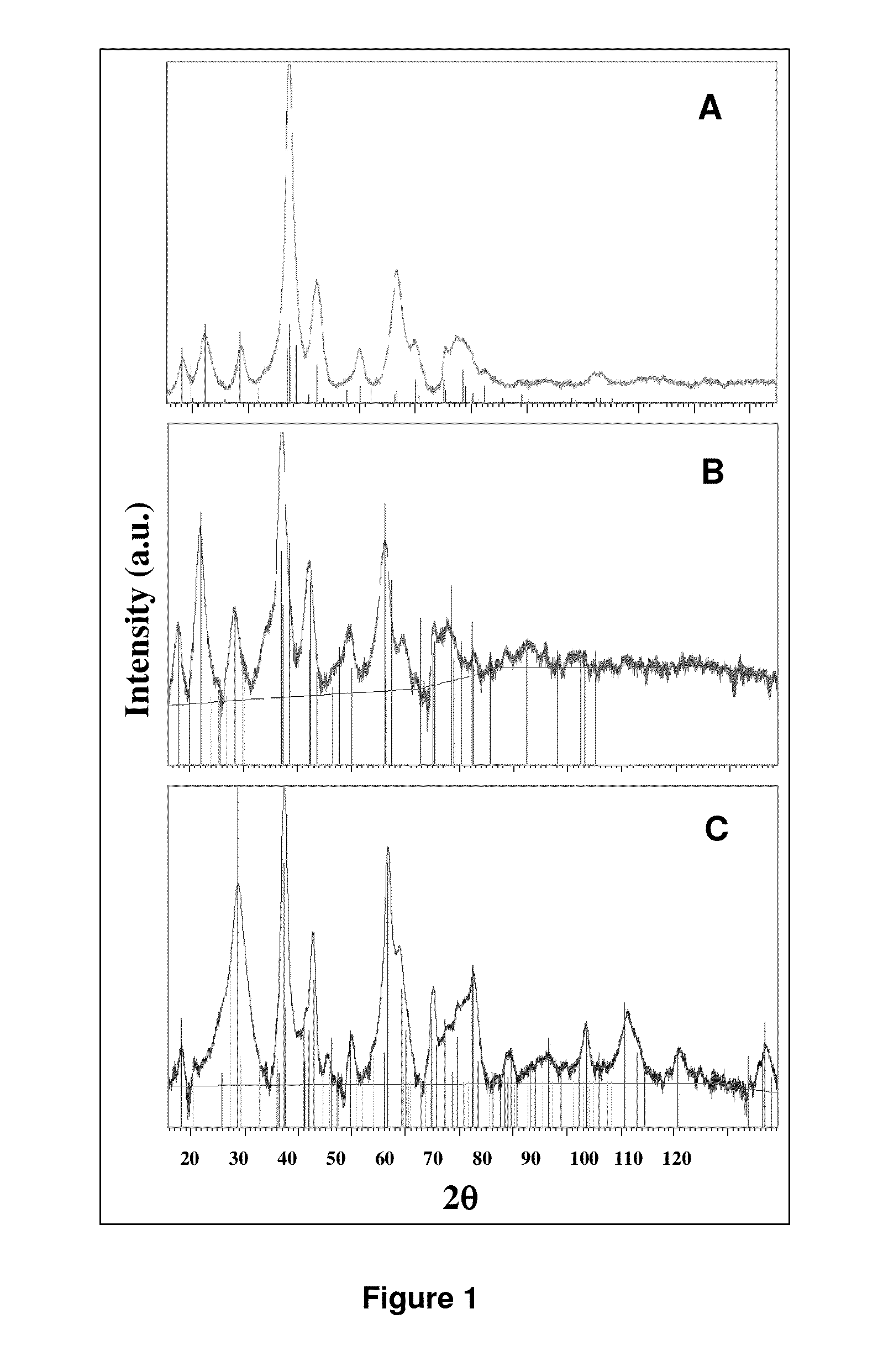

[0120]Sodium permanganate (≧97%) and manganese sulfate monohydrate (≧98%) were obtained from Sigma Aldrich and used without further purification. Manganese dioxide (>98%) was also obtained from Sigma Aldrich to use as a reference in formaldehyde removal tests. Manganese oxide samples were prepared using a chemical co-precipitation route. Manganese sulfate (MnSO4) and sodium permanganate (NaMnO4) are dissolved in distilled water. To the manganese sulfate aqueous solution, the sodium permanganate solution was added slowly with constant stirring such that the molar ratio of the resulting s...

example 2

[0156]In some embodiments of the invention, the device comprises an integrated-technology air cleaner (ITAC) capable of removing VOCs, and optionally particles and optionally ozone, from indoor air with a high efficiency. The device has approximately the same rates of removal of indoor-generated particles and VOCs in a typical single-family house, and also reduces indoor concentrations of outdoor-air VOCs and ozone. In some embodiments of the invention, the device has an air flow rate of 100 cfm, a removal efficiency of 70% for a range of VOCs and for 0.3 micrometer size particles, and a time-average power consumption less than 50 w.

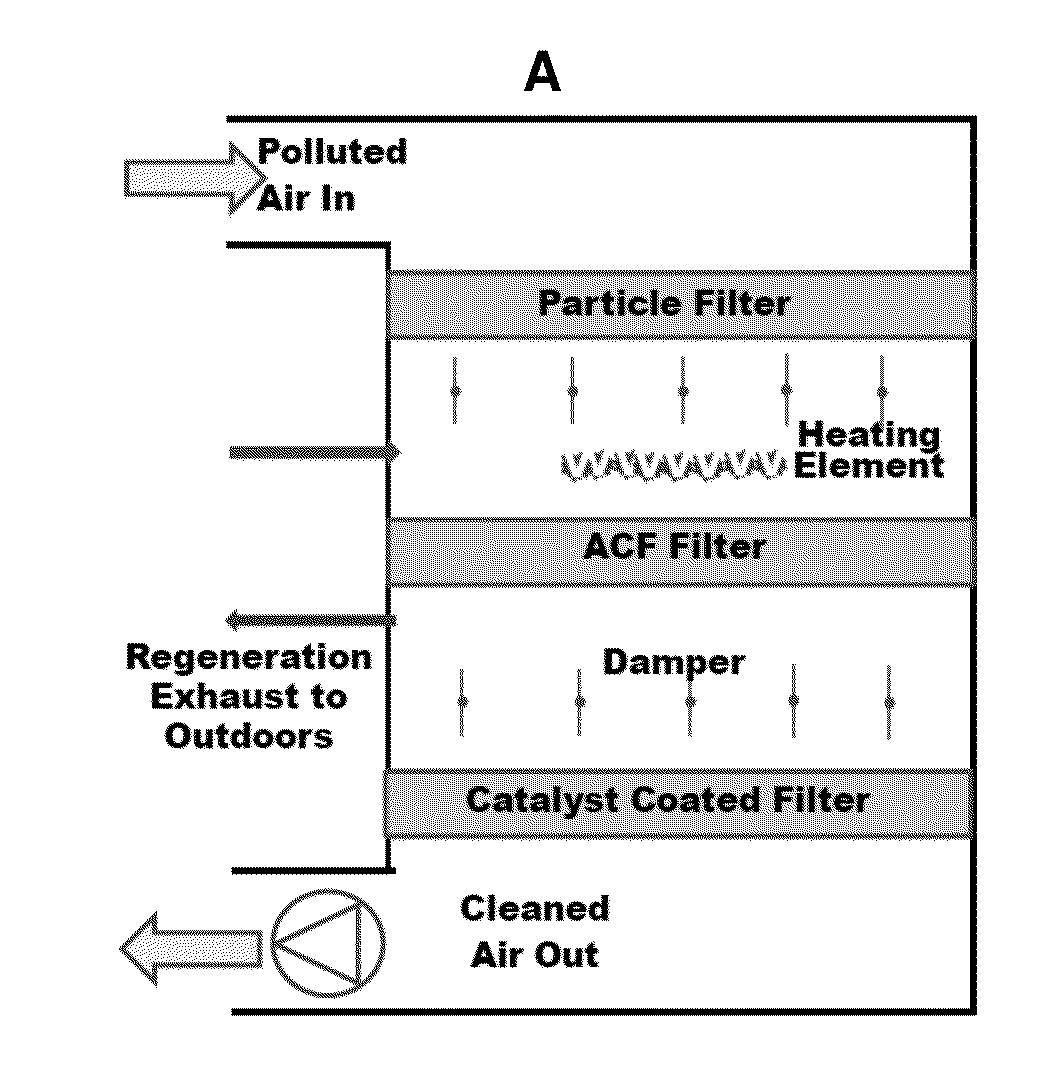

[0157]FIG. 5 shows a schematic of the design of the air cleaner which uses three air cleaning technologies in an integrated manner to remove particles, volatile organic compounds (VOCs), and ozone from indoor air. Indoor air enters from the top of the air cleaner and first passes through a particle filter that removes particles. The particle filter could...

example 3

Manganese Oxide Catalysts

[0160]In a field demonstration, deployment of a catalyst-treated filter reduces indoor formaldehyde concentrations by about 80%. Tests indicated that high humidity conditions do not significantly affect the performance of the manganese oxide catalysts. Test indicate little inactivation of the catalyst after long-term continuous use.

[0161]ACF Systems.

[0162]Heating air to regenerate the ACF media results in improved regeneration efficiency with respect to that achieved by directly heating the media, a finding that makes regeneration more practical using existing HVAC hardware. A double layer of ACF cloth shows improved performance for all VOCs, but most critically it results in a doubling of the removal efficiency for formaldehyde. To facilitate deployment of the air cleaning systems in existing buildings, including those with roof-top systems, we developed a conceptual design for an air cleaner that is connected to the ductwork of an existing HVAC system.

[016...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| molar ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com