Treatment method for recycling complex waste water in coal chemical industry

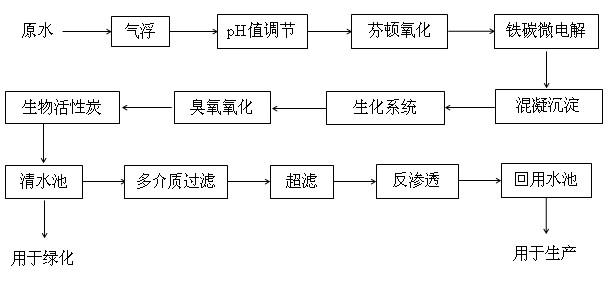

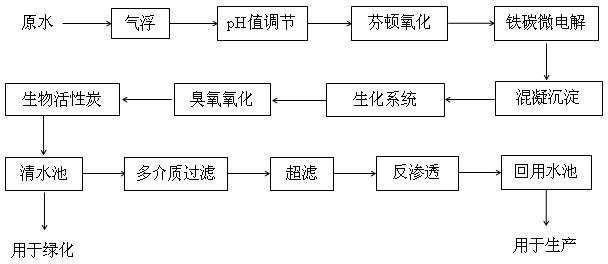

A technology that integrates waste water and treatment methods, applied in the field of water treatment, can solve the problems that waste water cannot be treated up to the standard, not to mention recycling, etc., and achieve the effects of improving unsatisfactory biochemical effects, great social value, and improving biochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

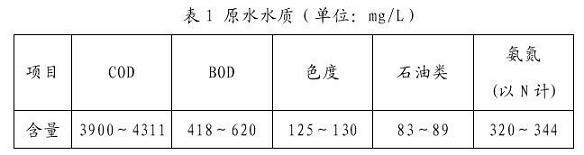

[0031] A pilot plant treatment of comprehensive wastewater from a coal chemical industry was carried out, with an inflow of 100L / h. The raw water quality is shown in Table 1.

[0032]

[0033] Coal chemical comprehensive wastewater is firstly mixed with 8% PAC aqueous solution and 1‰ PAM aqueous solution through a pipeline mixer. ≤4.2mg / L; the air flotation water is introduced into the Fenton oxidation pool, and the Fenton oxidation pool is used for FRP anticorrosion, and the dosage of the agent is 400mg / L of ferrous sulfate powder 2+ ion meter), hydrogen peroxide 2.5g / L (with 30% H 2 o 2 meter), the residence time is 40min; then the Fenton effluent is introduced into the iron-carbon micro-electrolytic cell, and the filling rate of the filler is 20%; after that, the pH value of the iron-carbon effluent is adjusted to 8.0 for coagulation and precipitation. After enhanced pretreatment, the COD removal rate of wastewater was about 27.1%, and the B / C ratio increased from 0.1...

Embodiment 2

[0039] The effluent from the clear water pool in Example 1 is introduced into the regeneration and reuse system of multimedia filtration + ultrafiltration + reverse osmosis, wherein the multimedia filter adopts pebbles (8-4mm) and quartz sand (4-2mm, 2-1mm) Use anthracite (0.5-1.0mm) as the filter material, and ensure that the maximum particle size in the influent is ≤200 μm through multi-media filtration; the ultrafiltration membrane adopts Toray's HFS-1010 ultrafiltration membrane, and maintains the SDI of the reverse osmosis influent through ultrafiltration ≤4; Toray’s TML10 anti-pollution membrane is used for reverse osmosis. After passing through the system, the conductivity of the effluent water is ≤50μs / cm, the desalination rate is ≥98%, the COD is ≤5mg / L, the ammonia nitrogen value is ≤1mg / L, and the water quality index meets the requirements for reuse. Require.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com