Low emission energy source

a low-emission energy source and low-emission technology, applied in the direction of machines/engines, liquefaction, lighting and heating apparatus, etc., can solve the problem of reducing the occurrence of greenhouse gasses. , the effect of increasing the generating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] So that the manner in which the above recited features of the present invention can be understood in detail, a more particular description of the invention, briefly summarized above, may be had by reference to embodiments, some of which are illustrated in the appended drawings. It is to be noted, however, that the appended drawings illustrate only typical embodiments of this invention and are therefore not to be considered limiting of its scope, for the invention may admit to other equally effective embodiments.

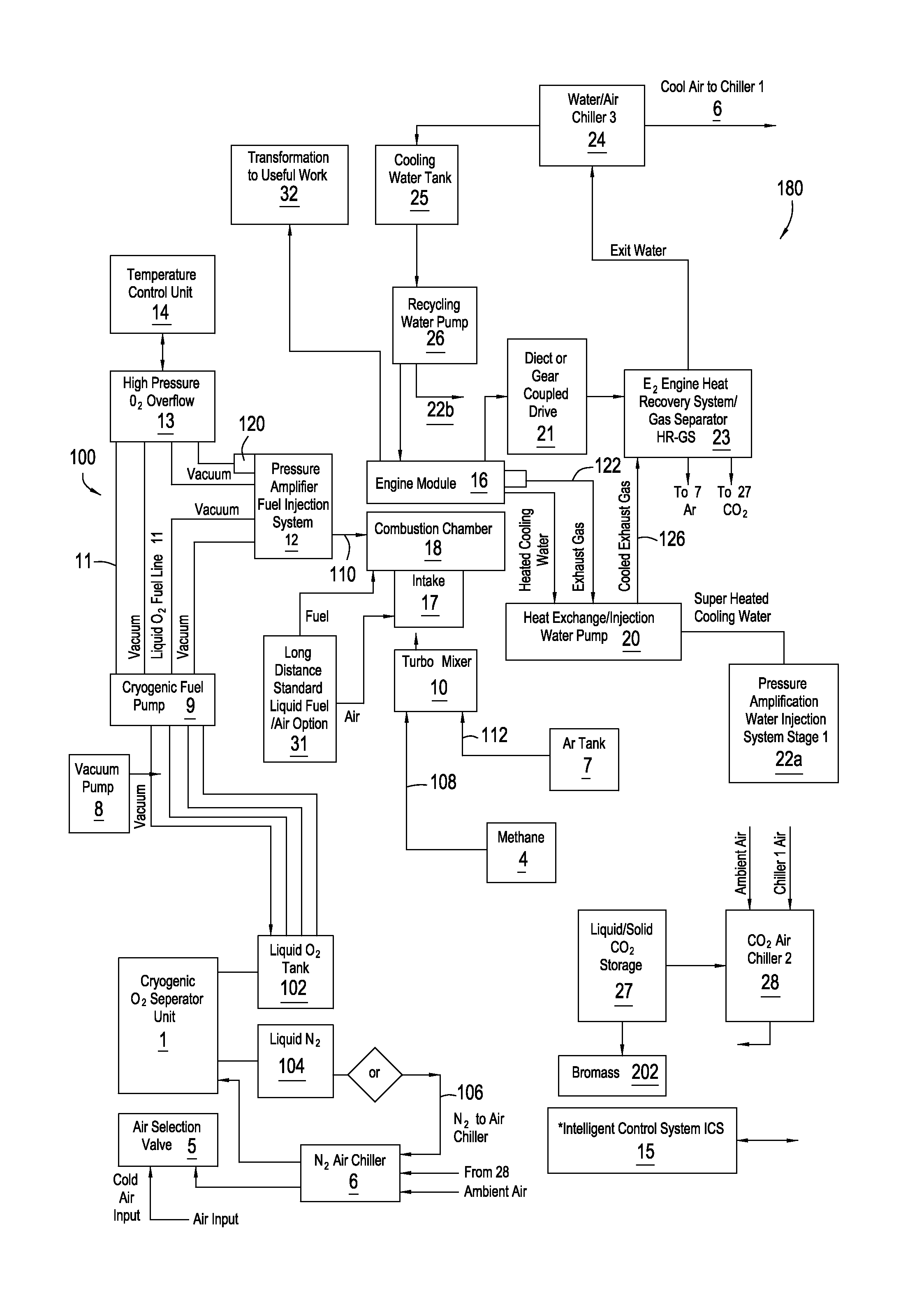

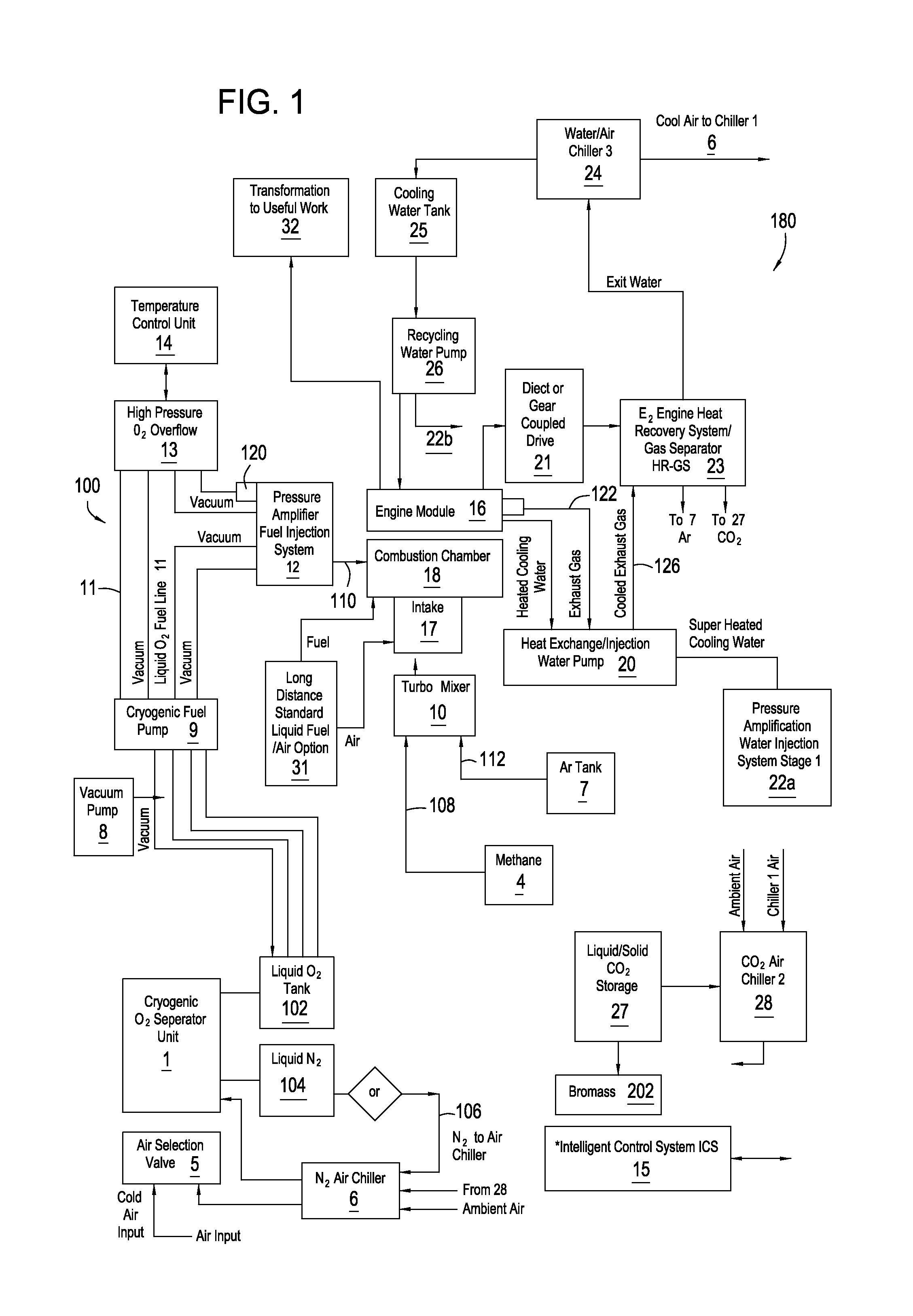

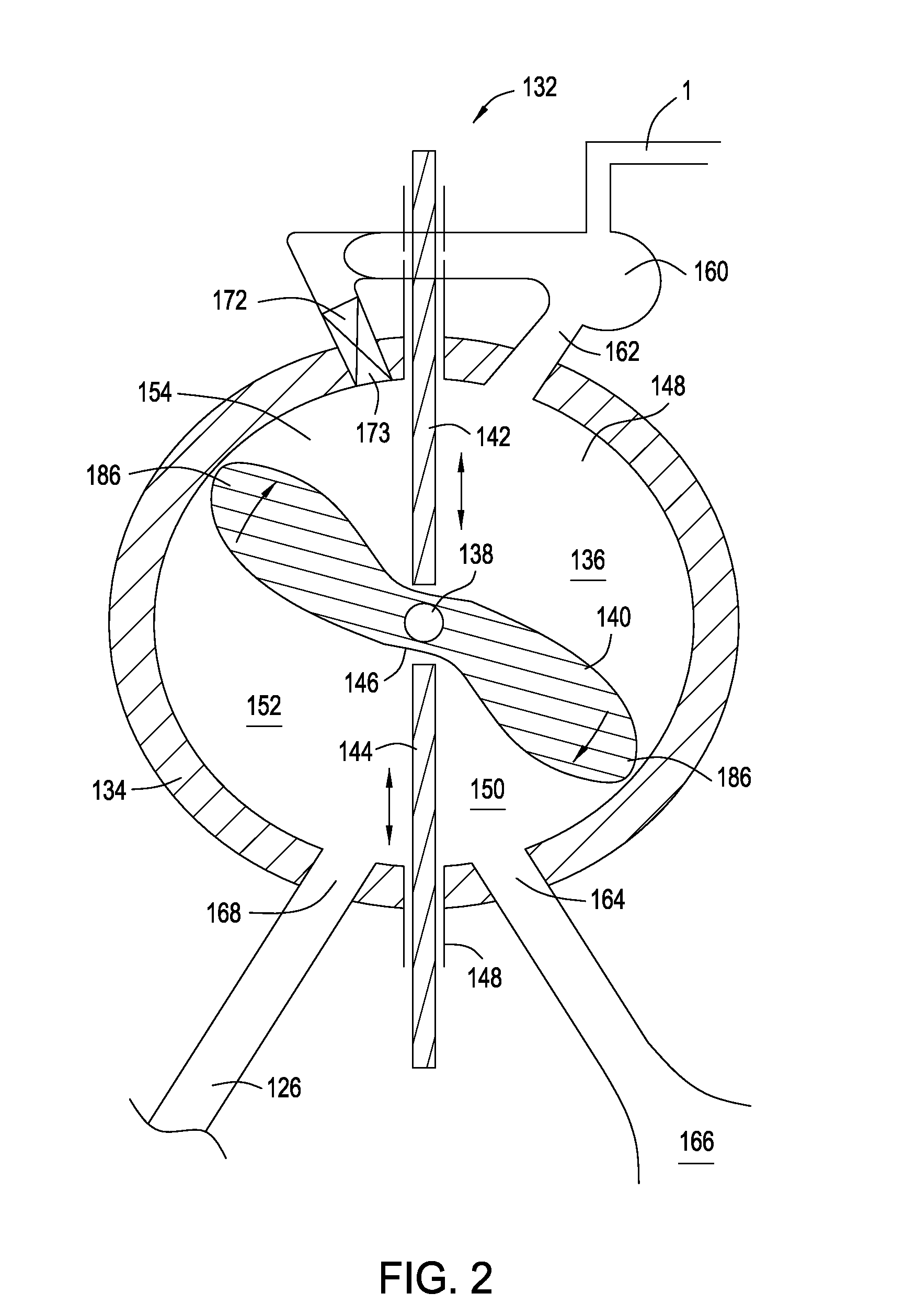

[0031]FIG. 1 is a schematic representation of an embodiment of the power generator of the present invention, showing the individual components and their interconnection useful for generating power with minimal emission and a relatively high efficiency. Essentially, in this embodiment, the major components of the invention include an internal combustion engine 16, such as a diesel cycle engine, an engine heat recovery and gas separator system 23 for the separation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com