Device and method for measuring gas-liquid chemical reaction rate based on volumetric method

A technology of chemical reaction rate and gas-liquid reaction, which is applied to the analysis of materials and instruments, can solve the problems of inability to apply high-pressure or high-temperature reaction conditions, increase indication errors and subjectivity, and difficulty in improving efficiency, so as to achieve stable and reliable test performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

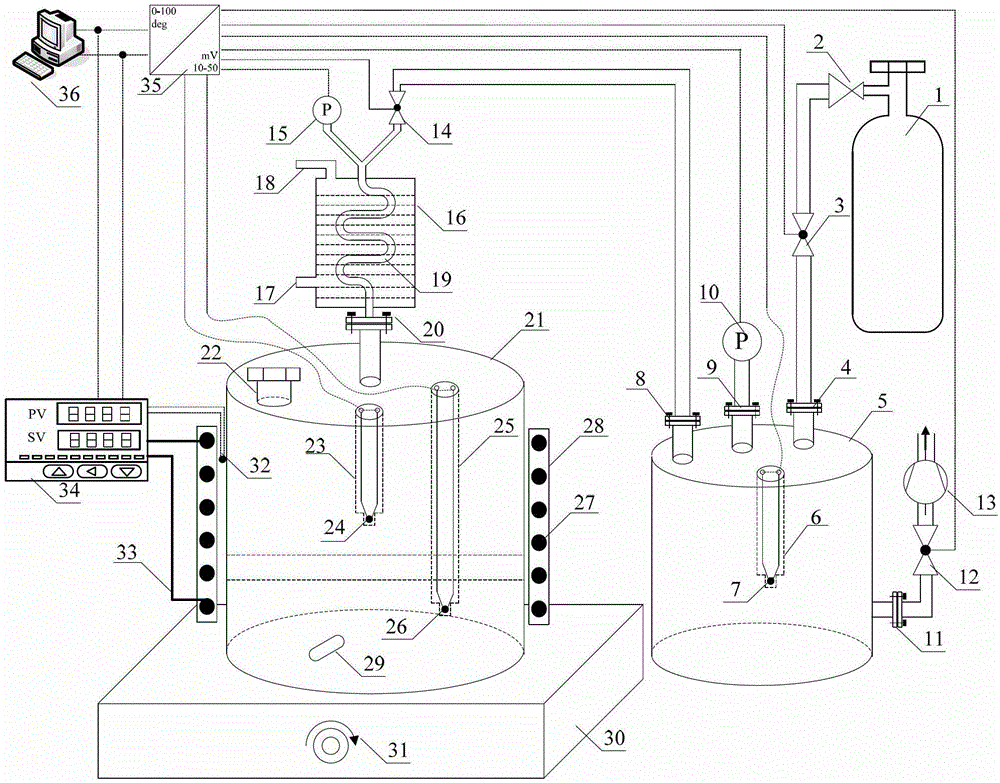

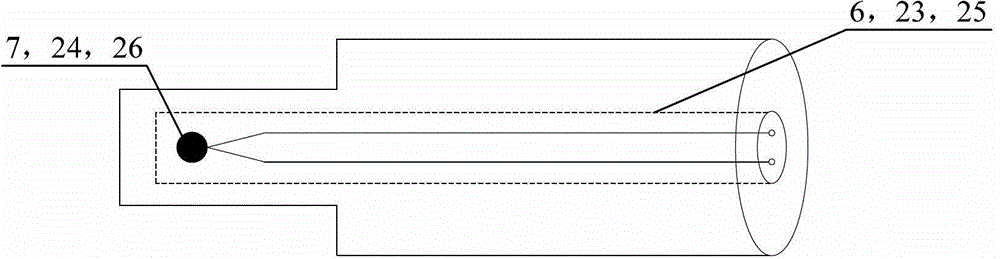

[0026] The embodiment of the present invention measures the chemical reaction rate of monoethanolamine solution (MEA) and carbon dioxide gas, selects 500mL of 30% MEA solution for use, the volume of metering chamber 5 is 500mL, the volume of gas-liquid reaction chamber 21 is 1000mL, metering chamber thermocouple 7, gas meter Both the thermocouple 24 and the liquid temperature measuring thermocouple 26 are first-class T-type thermocouples with an accuracy of ±0.5°C. The metering chamber pressure sensor 10 adopts a piezoelectric sensor with a pressure range of 0~1MPa and an accuracy of ±0.06%. The reaction chamber pressure sensor 15 adopts a piezoelectric sensor with a working pressure range of 0~0.2MPa, a maximum pressure of 1MPa, and an accuracy of ±0.06%. piezoresistive sensor. The pumping rate of the vacuum pump 13 is 0.5L / s, the gas source gas cylinder 1 to be tested is a 40L carbon dioxide gas cylinder, the maximum pressure is 15MPa, and the maximum range of the pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com