Convective seating and sleeping systems

a technology of convective seating and sleeping system, which is applied in the direction of fluid mattresses, chairs, sofas, etc., can solve the problems of significantly diminished gas bearing function, reduce the efficiency of stirling device, and significantly reduce the function of gas bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

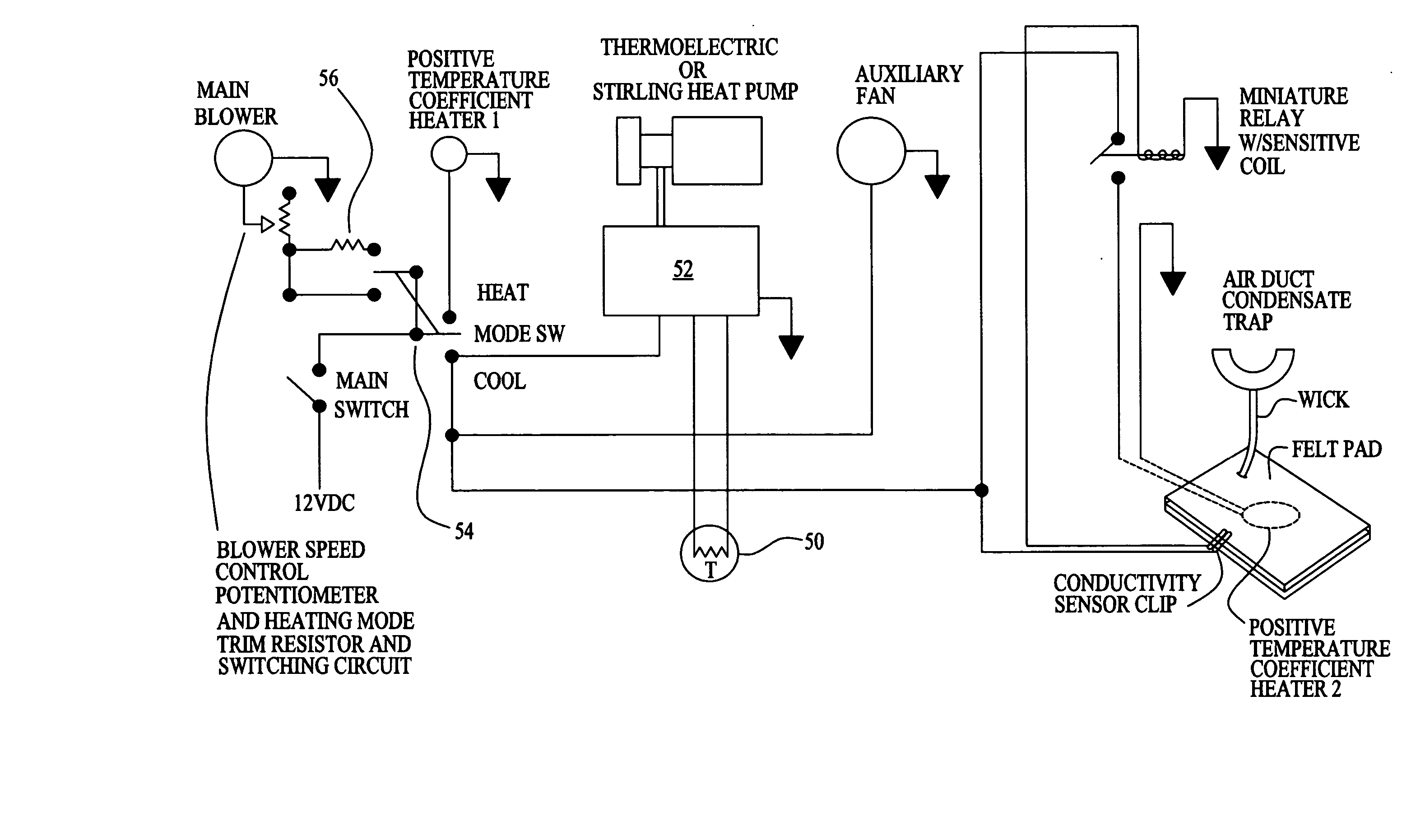

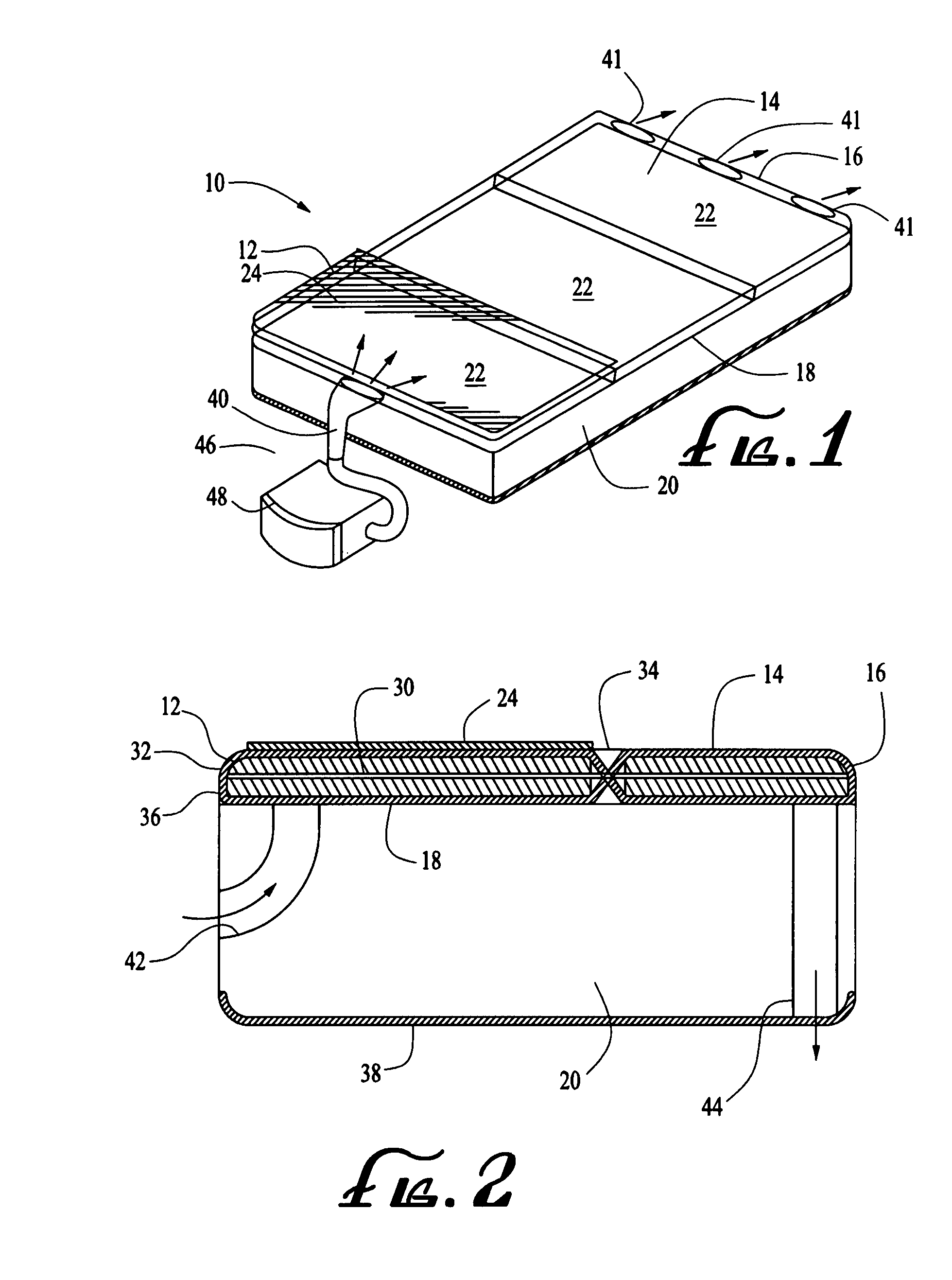

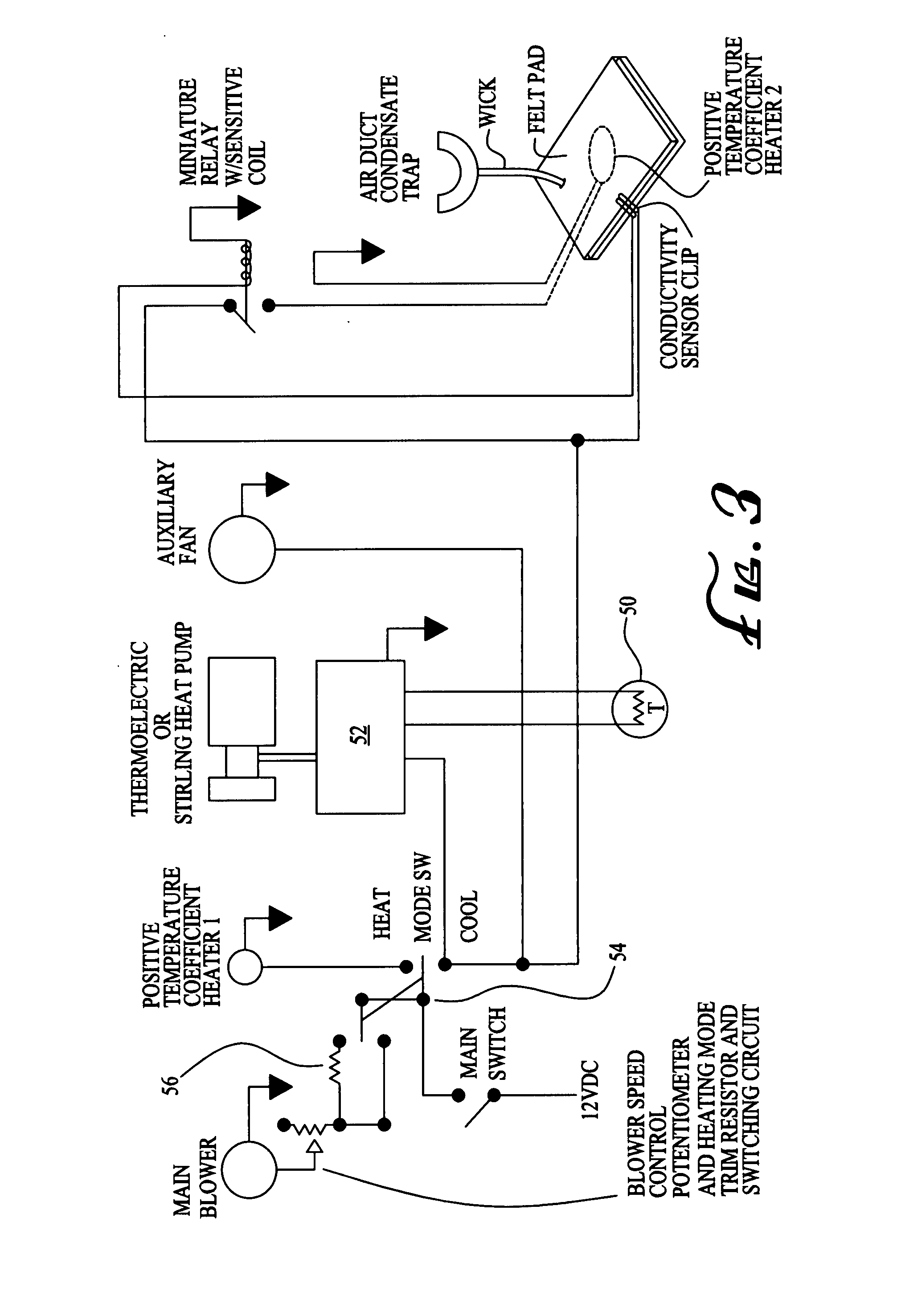

[0037]FIG. 1 is a perspective view of one embodiment of the convective cushion 10 as applied to a mattress for cooling and heating while a user is resting or sleeping. The convective cushion 10 includes a plenum 12 having a generally air permeable top surface 14 that is secured around a perimeter 16 to a bottom surface 18. The bottom surface 18 is in one or more embodiments generally impermeable to air and as shown in FIGS. 1 and 2 can be placed on a mattress 20 to make the bottom surface 18 generally impermeable. In one or more embodiments, the mattress 20 is a foam mattress, but the present invention includes the use of a futon, coil spring mattresses, inflatable mattresses or other structures made of other materials to support the plenum 12.

[0038] As shown in FIG. 1, the plenum 12 includes multiple pockets 22 made of a synthetic material woven into a mesh of approximately 4-6 strands per inch×4-6 strands per inch with each of the pockets 22 separately removable as part of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com