Super-resolution microscopic imaging method and system based on microcantilever and microsphere combined probe

A combined probe and microscopic imaging technology, which is applied in scanning probe microscopy, scanning probe technology, measuring devices, etc., can solve the problems of small imaging magnification, uncontrollable spreading area, and difficulty in practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

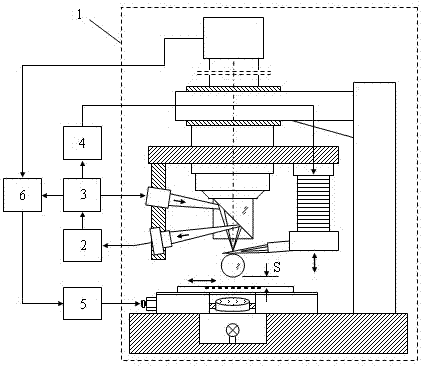

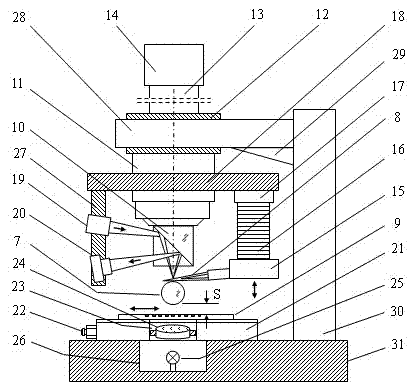

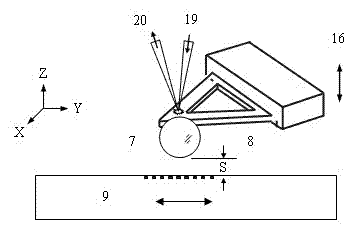

[0017] The super-resolution microscopy imaging method based on the microcantilever and microsphere combined probe is: the method of using the microcantilever and microsphere combined probe to lift the microsphere off the sample surface and the micro-nano feedback control method based on atomic force, and the introduction of atomic force microscope (AFM) microcantilever, to prepare a microcantilever-microsphere probe, which lifts the microsphere away from the surface of the sample and at the same time very close to the sample surface; introduces lasers, semi-transparent and semi-reflective prisms, position detectors and piezoelectric ceramics, etc., through micro-nano Feedback control controls the distance between the microsphere and the sample in the near-field range, breaks through the optical diffraction limit of 200nm, and realizes super-resolution optical microscopy imaging of the sample; cooperates with the stepping mobile stage to realize the lateral adjustment between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com