Side pressing block adjusting mechanism, stamping die and stamping equipment

A technology of adjusting mechanism and adjusting parts, which is applied in the field of stamping processing, can solve the problems of inconvenient assembly and disassembly, difficulty in meeting production needs, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

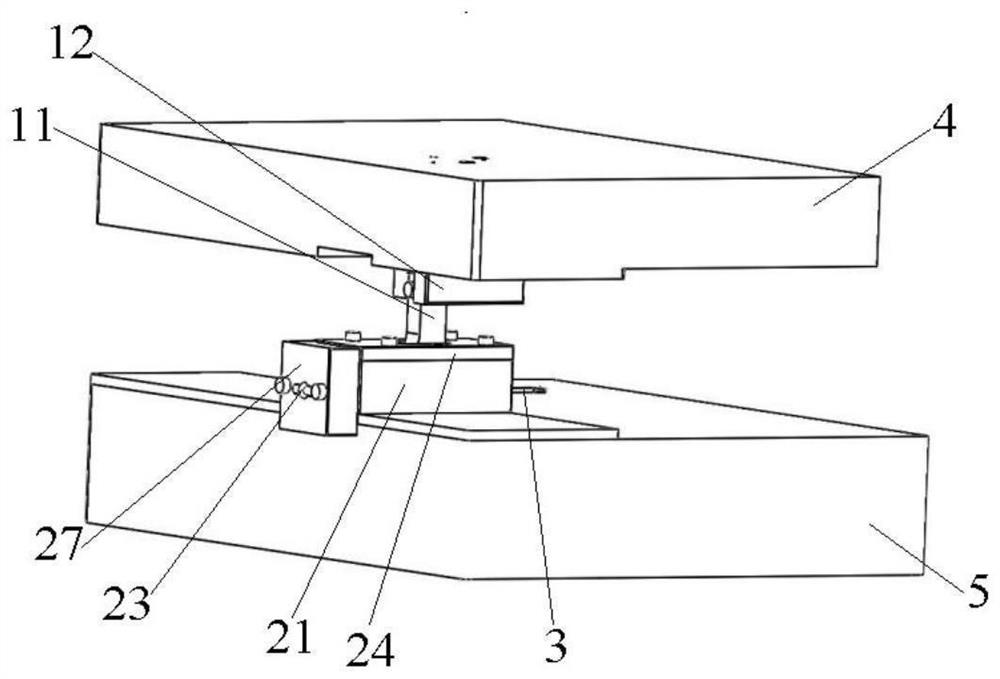

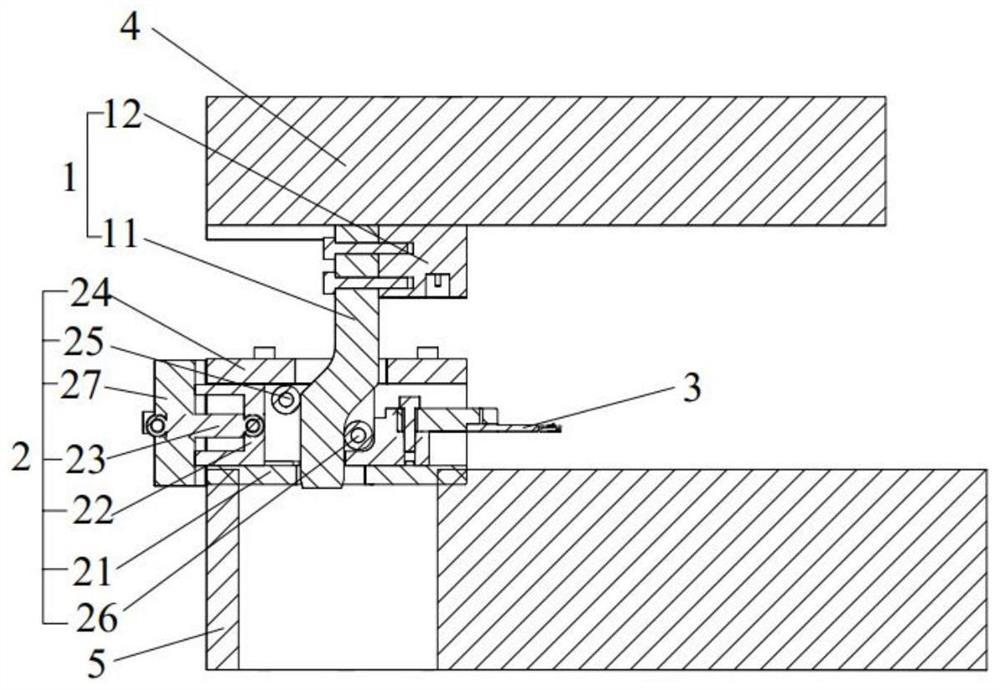

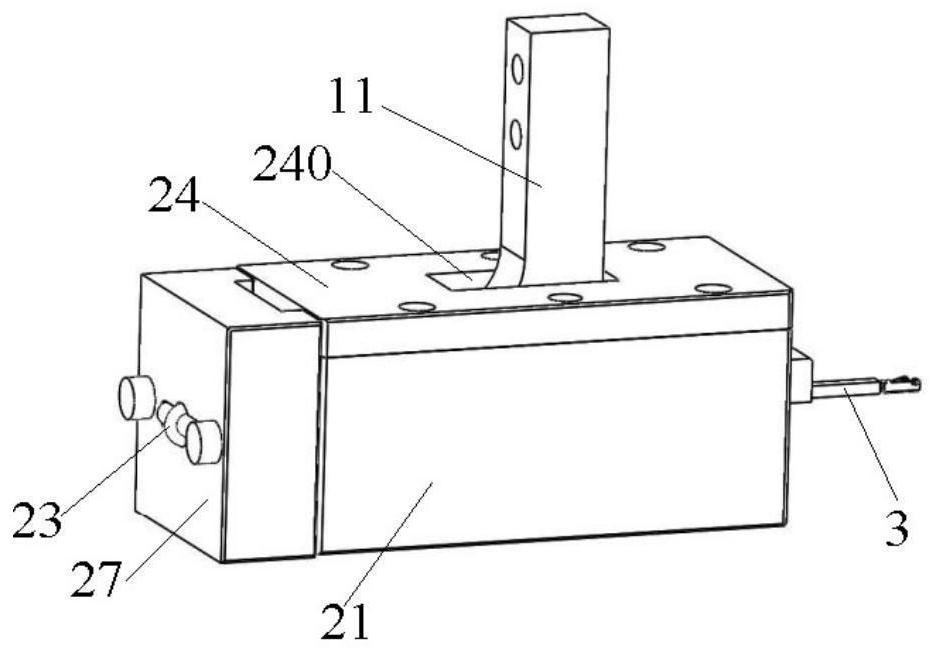

[0053] Such as Figure 1 to Figure 7 The shown side pressure block adjustment mechanism includes an adjustment assembly 1 , a slide assembly 2 , an adjustment mandrel 3 and a blocking member 27 . Wherein, the adjustment assembly 1 includes an adjustment member 11 composed of a body part 111 , an adjustment part 112 and a connection part 113 , a driving part and an adjustment fixing seat 12 . The two opposite sides of the adjustment part 112 are respectively formed with a first action part 114 and a second action part 115 . The sliding assembly 2 includes a base 21 , a sliding block 22 slidably connected to the base 21 , and a reset biasing member 23 for driving the sliding block 22 to reset. The sliding block 22 is provided with a avoidance portion 220 for the adjusting member 11 to enter and exit, and the sliding block 22 can be driven by the adjusting member 11 to slide along a second direction intersecting with the first direction in which the adjusting member 11 enters an...

Embodiment 2

[0065] A kind of stamping die of the present embodiment, such as Figure 1 to Figure 7As shown, the side pressure block adjustment mechanism, the upper mold base 4 and the lower mold base 5 of the first embodiment are included. The adjustment assembly 1 is fixedly installed on the upper mold base 4, specifically, the adjustment fixing base 12 is fixedly installed on the bottom of the upper mold base 4 through fasteners such as bolts, and the connecting part 113 of the adjustment member 11 is fixedly installed on the adjustment part 11 through fastening belts such as bolts. On the fixed seat 12. The lower die base 5 is arranged below the upper die base 4 , opposite to the upper die base 4 , and the sliding assembly 2 is fixedly mounted on the lower die base 5 . It should be noted that the stamping die of this embodiment also includes other conventional structures such as a punch, a die, an upper die assembly such as an upper template, an upper template fixing plate, a stripper...

Embodiment 3

[0068] A stamping device of this embodiment, such as Figure 1 to Figure 7 As shown, the stamping die in Example 2 is included. Other structures, such as the mounting frame, are not described and limited in detail, and are conventional structures of existing stamping equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com