Parallelly connected capacitance type capacitance pressure sensor

A pressure sensor and capacitive technology, which is applied in the direction of fluid pressure measurement, instruments, and measuring force using capacitance changes, can solve the problems of small signal-to-noise ratio, large internal resistance, and increased relative capacitance change, and achieve increased sensitivity, The effect of wide measuring range and increased relative capacitance change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

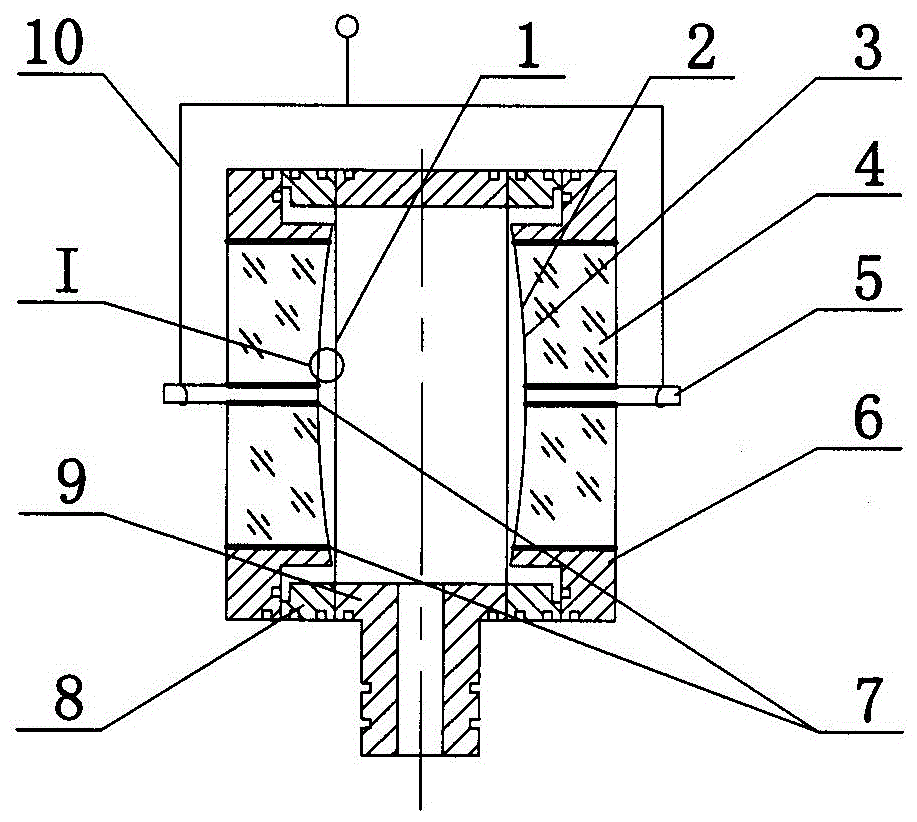

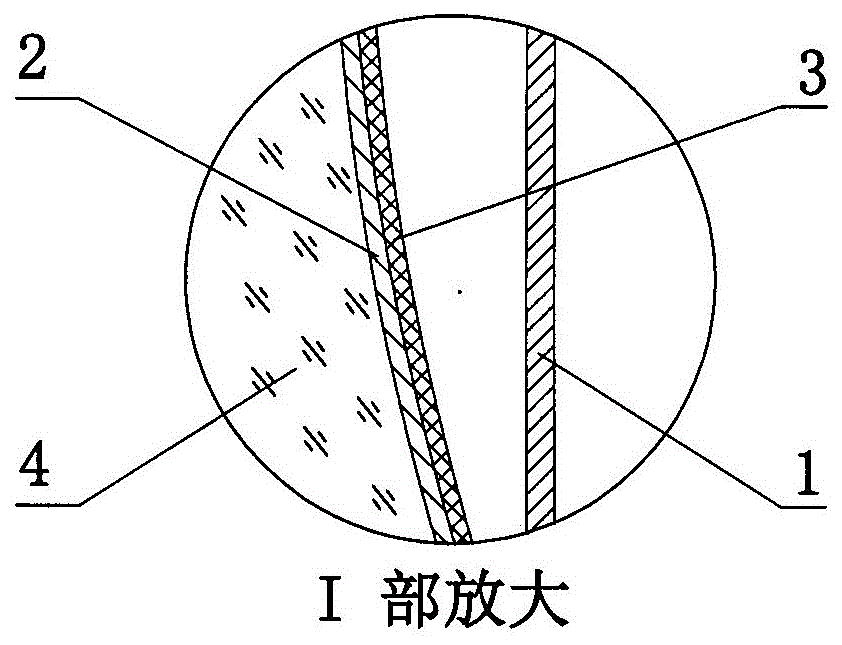

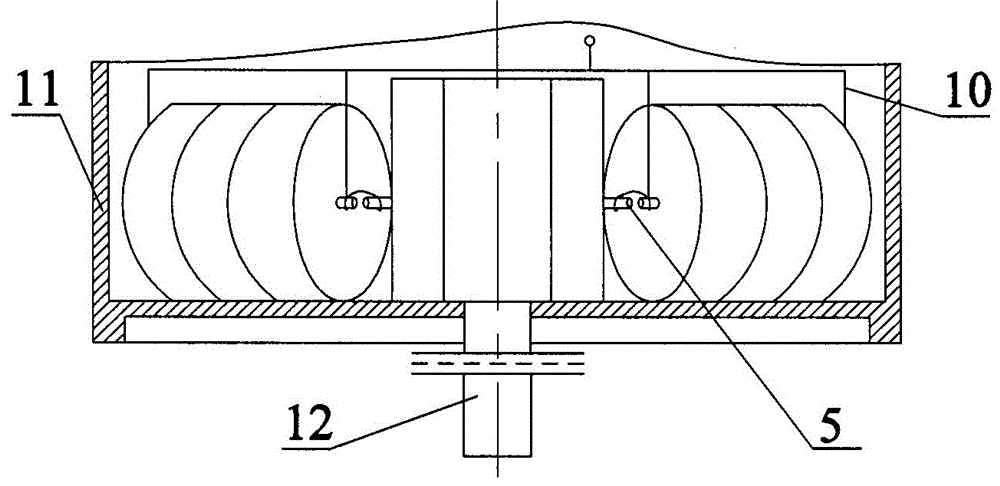

[0024] according to Figure 1~10 The specific structure of the present invention will be described in detail. The parallel capacitive capacitive pressure sensor includes a matching shell 6, a fixed electrode assembled with the matching shell 6, a sapphire insulator 4, and a conductive film layer 2, an insulating film layer 3, a tubular lead electrode 5, and a sapphire insulator concave paraboloid. Welding ring 8, movable electrode 1, and pressure port. The pressure leading port is a pressure leading port 9 with a common welding seat or a parallel pressure leading port 12. At least two of the same specifications are assembled in the matching shell 6, the transition welding ring 8, and the fixed electrode and the moving electrode 1 in the common welding seat 9. The capacitive pressure sensor connected with the tubular lead electrode 5 is connected to a common welding seat pressure introduction port 9 or a parallel pressure introduction port 12. The fixed electrode is connected b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com