Micro electromechanical system piezoelectric transducer and manufacturing method thereof

A technology of piezoelectric transducers and micro-electromechanical systems, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of transducer static Capacitance cannot be effectively reduced, weakening the effectiveness of the series connection of array elements, and the inability to directly realize the electrical series connection of array elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

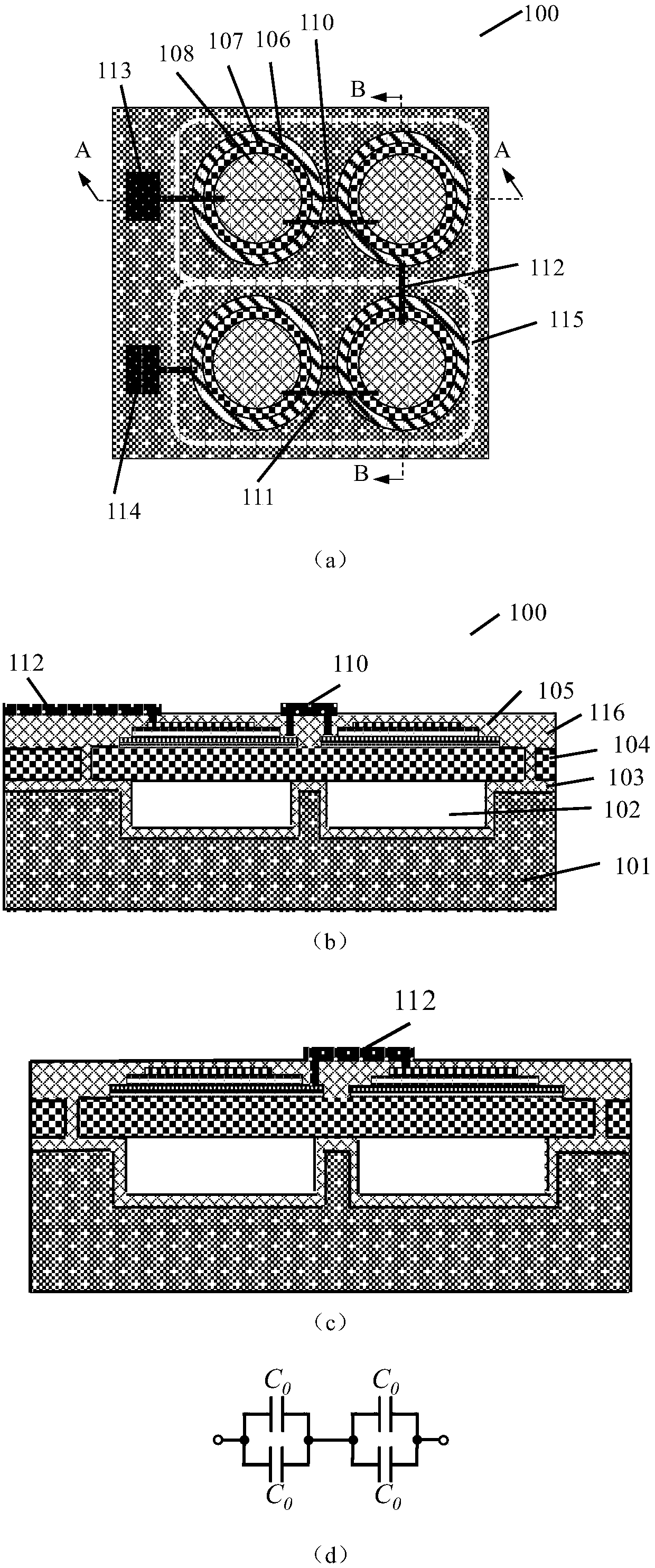

[0066] This embodiment serves as a top view of a typical array MEMS piezoelectric transducer as figure 1 as shown in (a), figure 1 (b) is along figure 1 Sectional view of line A-A of (a); figure 1 (c) is along figure 1 (a) Cross-sectional view of line B-B. like figure 1 As shown in (a), the piezoelectric transducer 100 in this embodiment is composed of four piezoelectric array elements. like figure 1As shown in (b), the transducer consists of a substrate 101 including four cavities 102, a buried oxide layer 103 and a device layer 104 on the substrate 101, a piezoelectric stack 105 on the device layer 104, and an insulating layer 116 located on the piezoelectric stack 105 . The buried oxide layer 103 and the device layer 104 together constitute the supporting layer of the transducer; the piezoelectric stack 105 is composed of a piezoelectric seed layer 106 , a lower electrode 107 , a piezoelectric functional layer 108 and an upper electrode 109 . The four array elements...

Embodiment 2

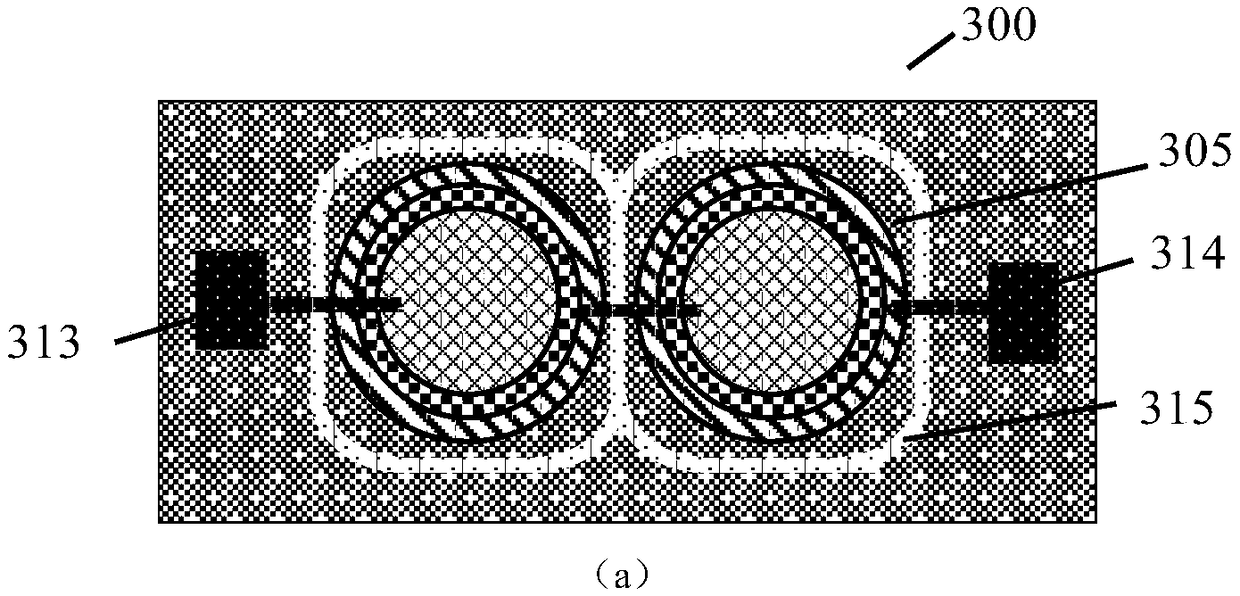

[0075] image 3 (a) is another example proposed by the present invention, two piezoelectric array elements form a row, and an electrical series is formed between the array elements, image 3 (b) for image 3 (a) Sectional view. refer to image 3 , the piezoelectric transducer 300 is composed of two piezoelectric array elements, and the transducer consists of a substrate 301 containing two cavities 302, a buried oxide layer 303 and a device layer 304 located on the substrate 301, located in the device Piezoelectric stack 305 on top of piezoelectric stack 304 , insulating layer 316 on top of piezoelectric stack 305 , and solderable electrode layers 317 , 318 on top of insulating layer 316 . Among them, the buried oxide layer 303 and the device layer 304 together constitute the supporting layer of the transducer; the piezoelectric stack 305 is a double piezoelectric stack, which consists of the piezoelectric seed layer 306, the lower electrode 107, and the first piezoelectric ...

Embodiment 3

[0082] Figure 4 The present invention proposes a piezoelectric array transducer with two array elements connected in series and a manufacturing method thereof.

[0083] 1) Reference Figure 4 (a), (b), the process starts from the common wafer substrate 401, and adopts deep reaction ion etching (DRIE) or reaction ion etching (RIE) method according to the design of the transducer A plurality of cavities 402 are formed by etching on the surface of the wafer; and then a layer of oxide 403 is evenly deposited.

[0084] 2) Reference Figure 4 (c), (d), introduce a piece of SOI (Silicon on insulator) wafer 500 , which is composed of substrate layer 501 , buried oxide layer 503 and device layer 504 . Combine SOI wafer 500 with Figure 4 (b) The wafers with the cavity 402 and the oxide layer 403 are bonded face to face at high temperature to form a bonded new wafer 600 .

[0085] 3) Reference Figure 4 (e) The substrate layer 501 and the buried oxide layer 503 of the wafer 600 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com