Method for quickly and accurately confirming friction coefficient in metal forming processes

A plastic forming and friction coefficient technology, applied in the field of metal plastic processing, can solve the problems that cannot consider the plastic deformation and hardening behavior of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

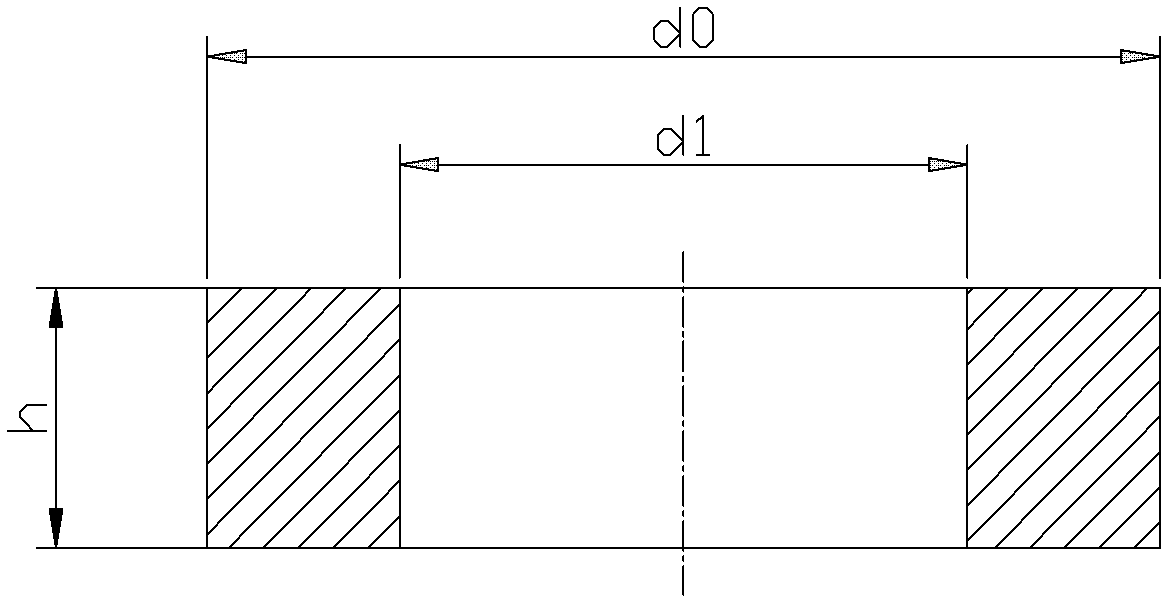

[0032] The experimental blank is Through analysis, it is determined to process according to D:d:H=3:2:1. The outer diameter of the ring is 18mm, the inner diameter is 12mm, and the height is 6mm. Turning is used to process the ring blank according to the design scheme. In this experiment, two groups of specimens were used for the experiment, and each group had three samples. The average striking height of the first group of specimens was 2.4mm, and the average striking height of the second group of specimens was 2.8mm. The experimental results are shown in Table 1.

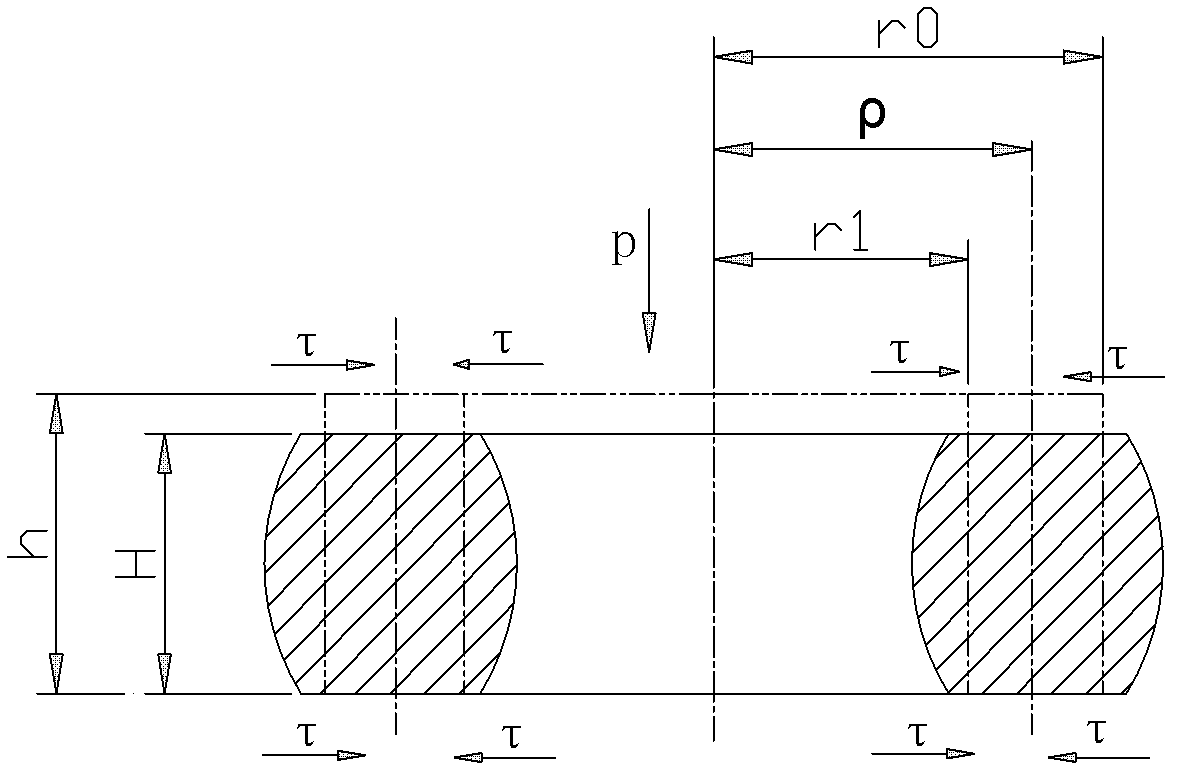

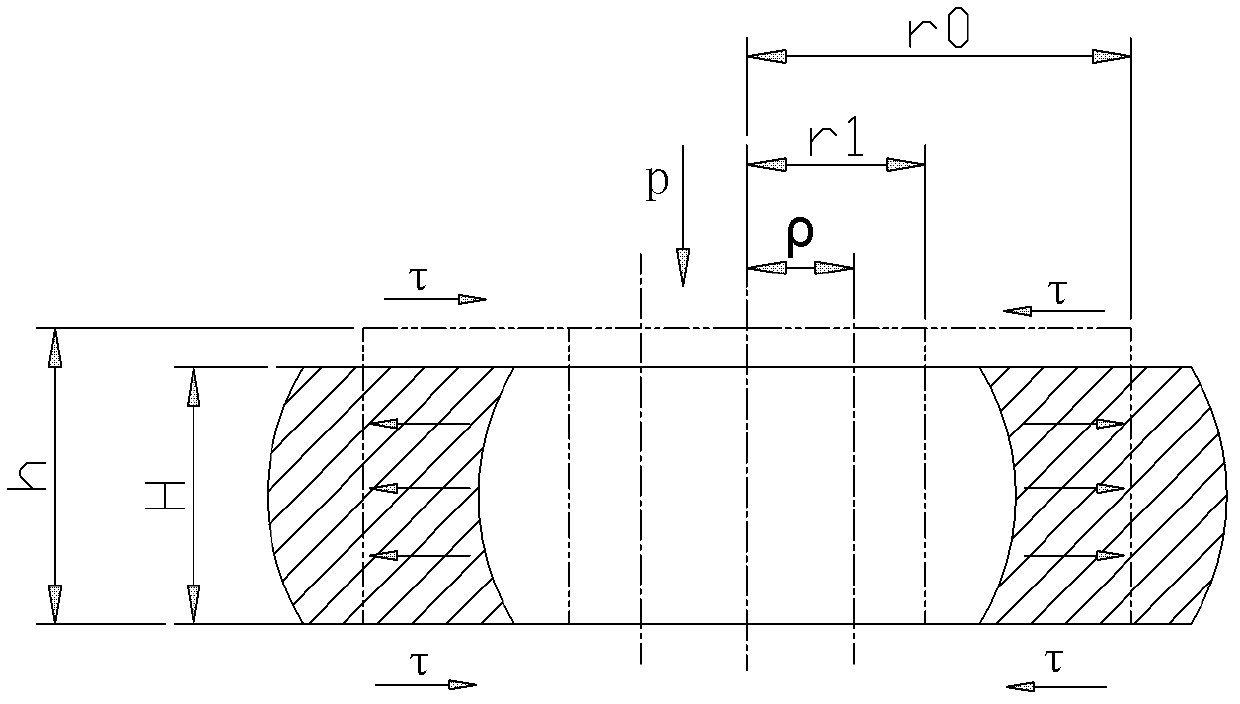

[0033] Since ring upsetting is an axisymmetric problem in both geometry and load, the axisymmetric geometric model of the part is discretized by using the symmetry of the ring part, and the axisymmetric 4-node quadrilateral element is used for finite element modeling, and applie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com