Method for manufacturing a reinforced structural component, and article manufactured thereby

a technology of reinforced structural components and manufacturing methods, applied in the direction of load-supporting pillars, transportation and packaging, other domestic articles, etc., can solve the problems of difficult implementation of prior art approaches and incompatibility of processes with high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is directed to a method for manufacturing a reinforced structural component, such as a pillar, frame or other structural member for a motor vehicle, a building structure, or the like. While the present invention will have utility in the fabrication of metallic and nonmetallic components, it will find particular advantage in fabrication of structural components which include metallic portions. In particular, the present invention is readily adapted for use in high speed metal forming operations such as roll forming.

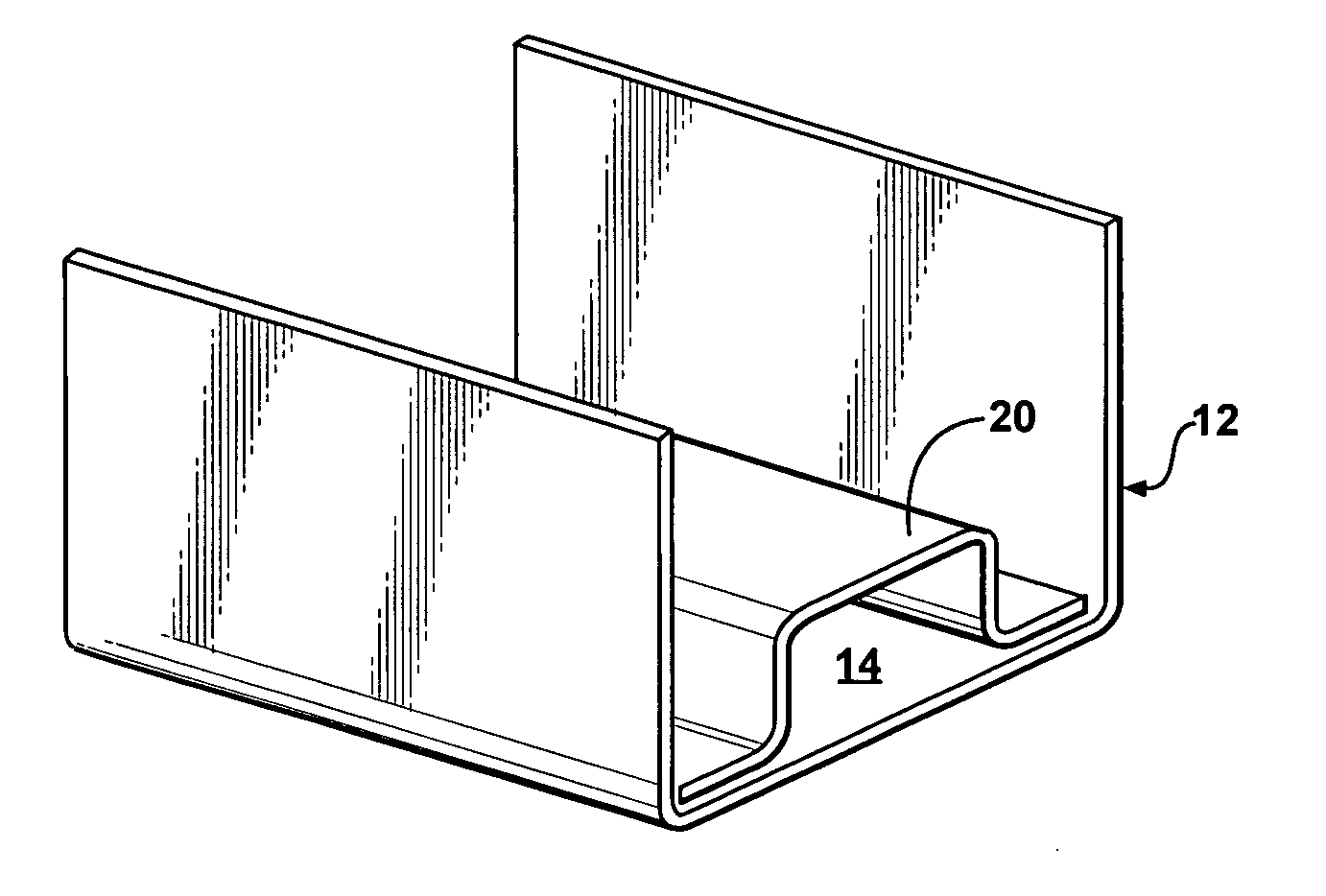

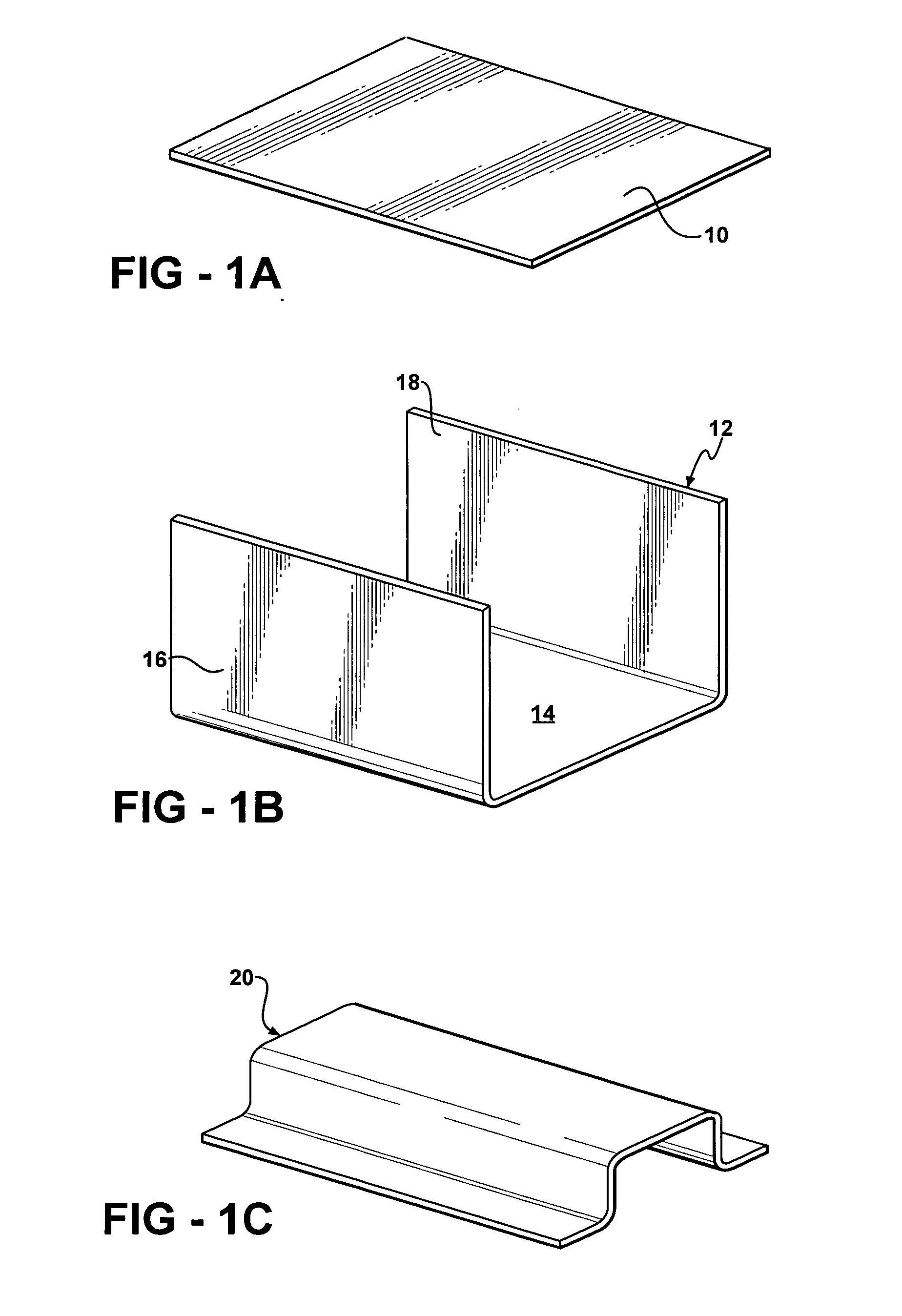

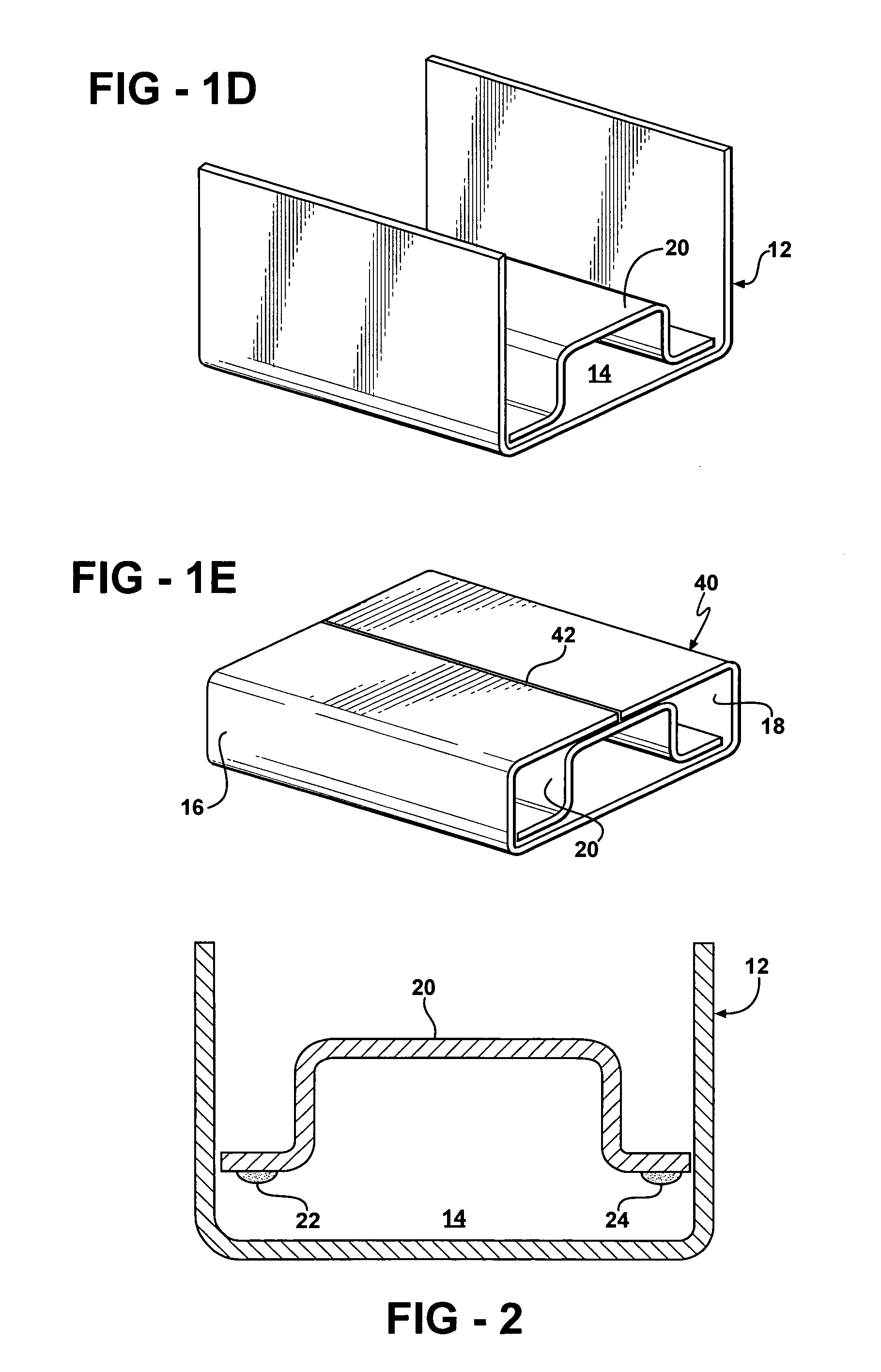

[0020] The present invention will be explained with reference to FIGS. 1A-1E which are schematic depictions of a general process according to the present invention. The process starts, as is shown in FIG. 1A, with a body of a sheet material 10. The sheet material 10 may comprise a ferrous or nonferrous metal, or it may comprise a body of another deformable material such as a polymeric material. As illustrated in FIG. 1, the body of sheet mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| mechanical structure | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com