Container cap

A technology of container cover and container body, applied in the field of container cover, can solve the problems that the end plate cannot fully seal the annular space, increase the difficulty of injection mold design, the leakage of container mixture, etc., and achieve the effect of easy disassembly/assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

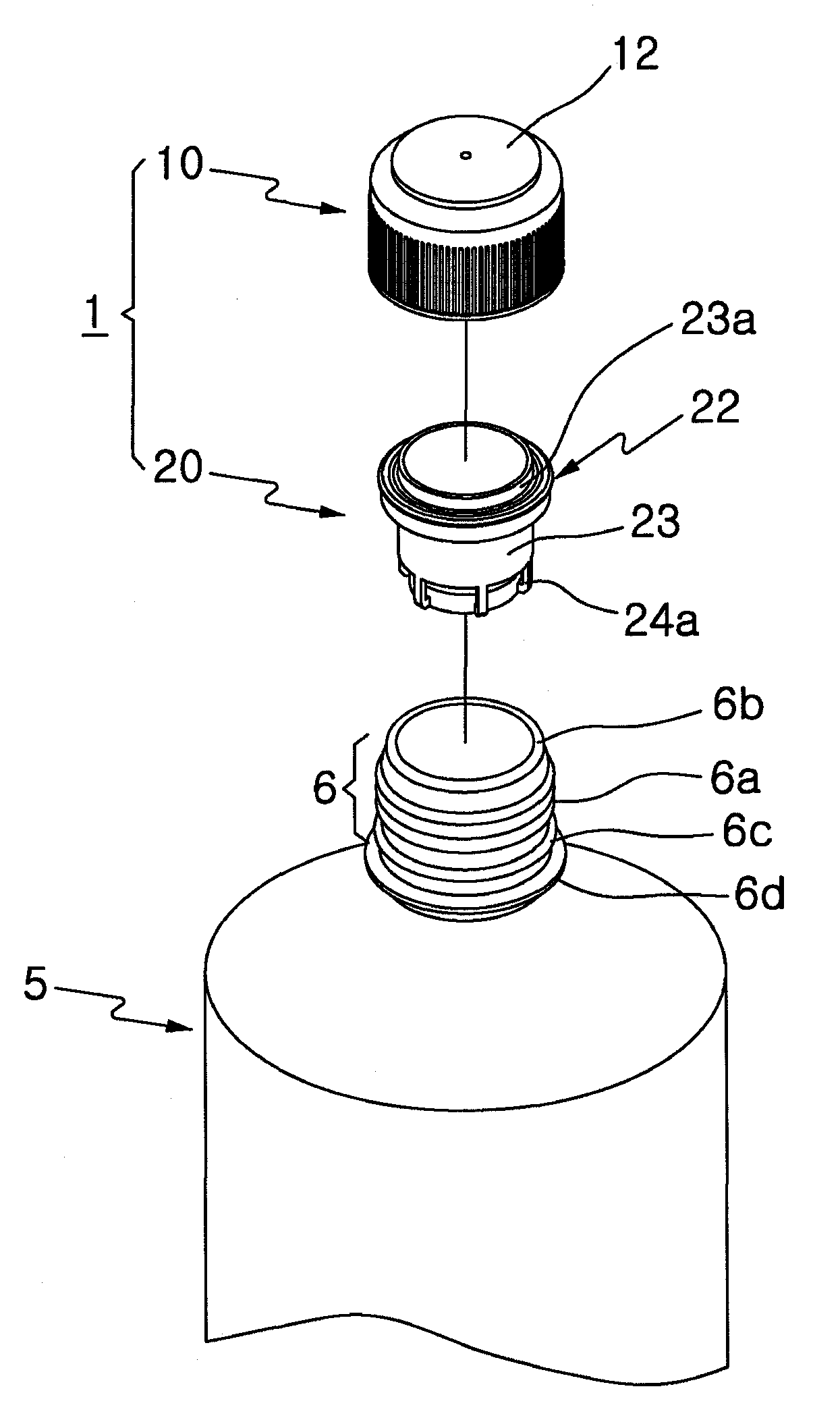

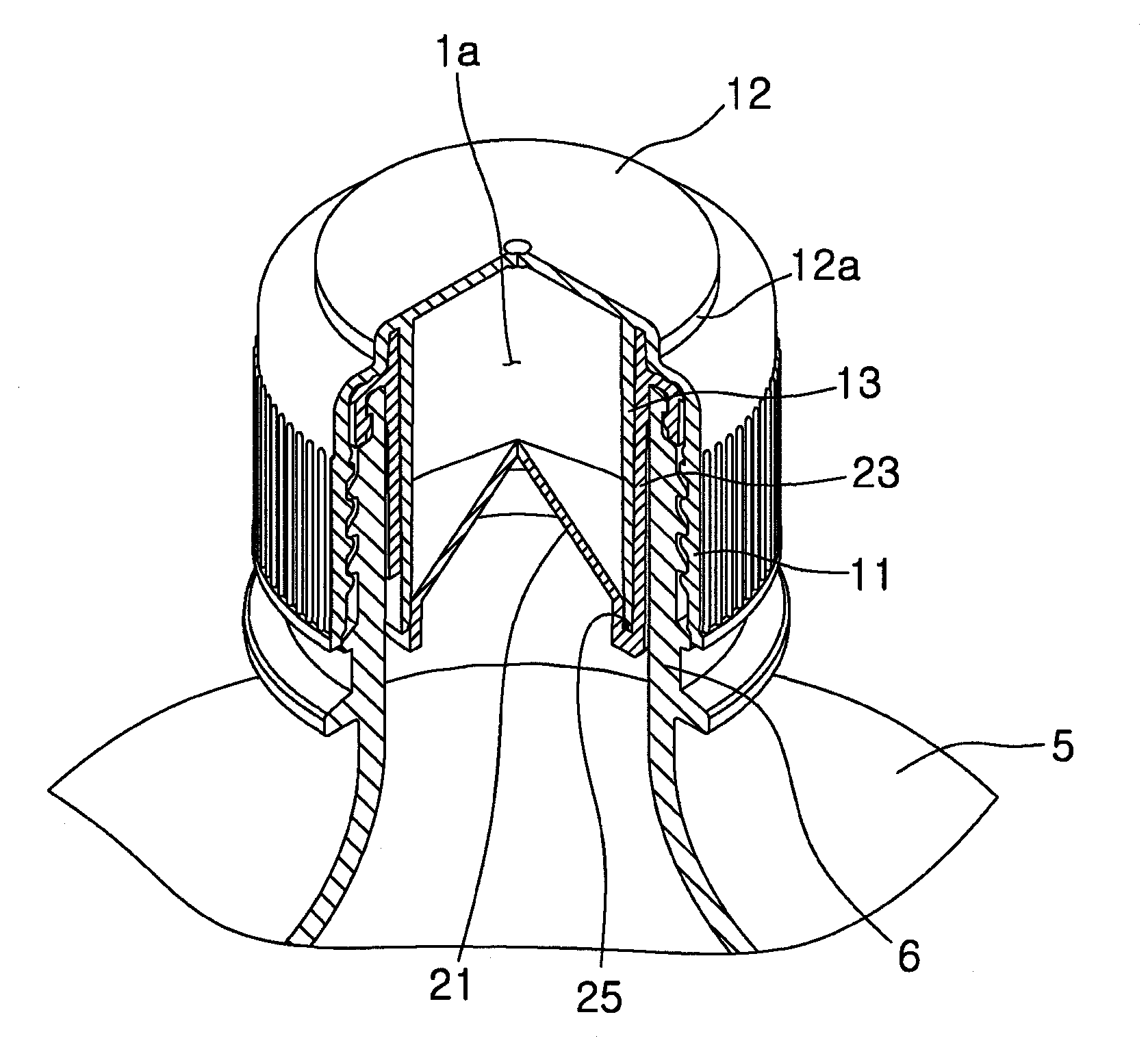

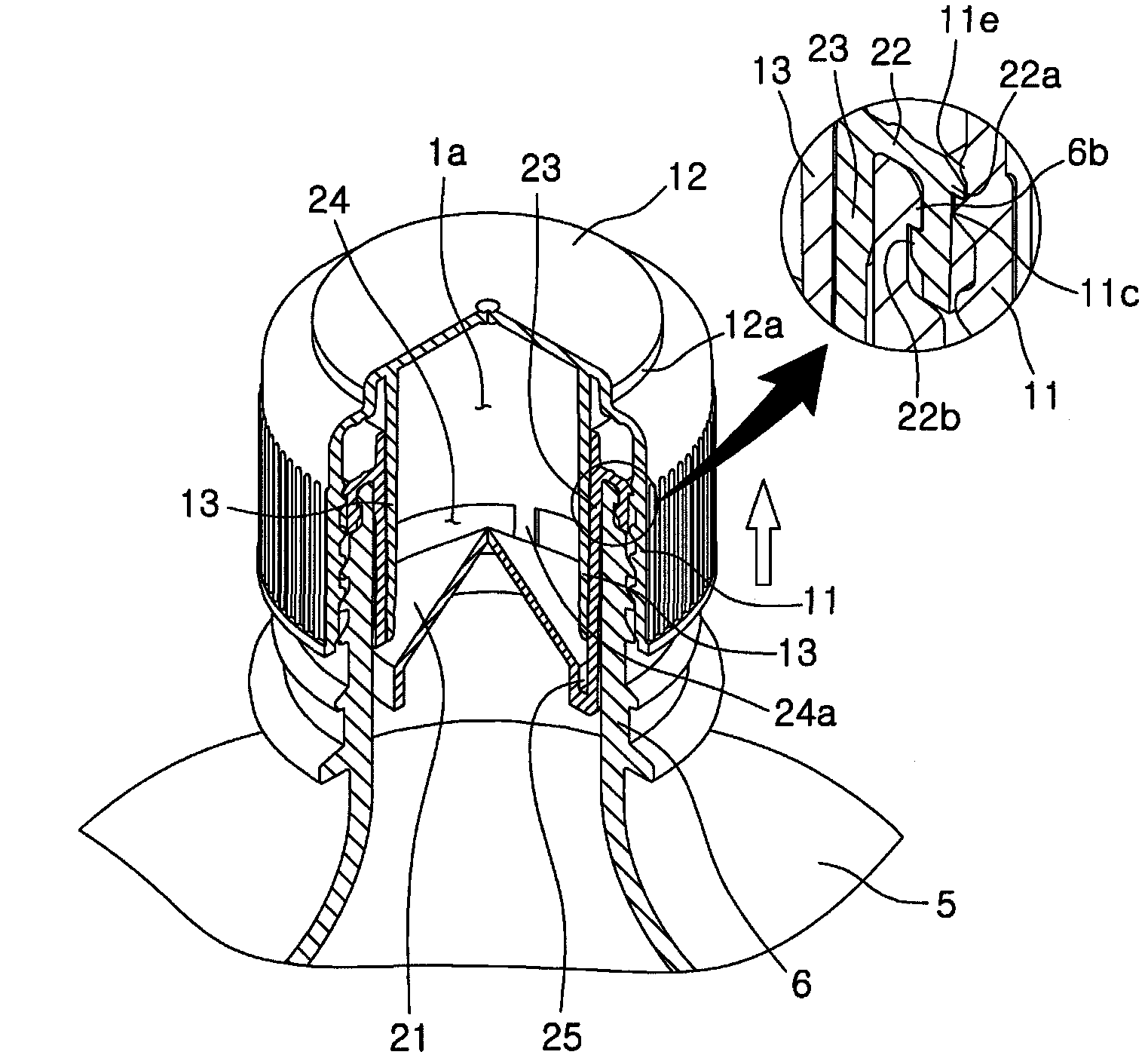

[0052] Next, the container cap of the present invention will be described with reference to the accompanying drawings.

[0053] figure 1 It is an exploded perspective view showing the structure of the container cap of the preferred first embodiment of the present invention. Figure 2 to Figure 4 Each is a cutaway perspective view for sequentially explaining the operation of the container cap according to the preferred first embodiment of the present invention. Figure 5 to Figure 8 Each is an axial sectional view for sequentially explaining the operation of the container cap according to the preferred first embodiment of the present invention. Figure 9 and Figure 10 It is a process cross-sectional view showing step by step the process of packing an additive in the container cap of the first embodiment.

[0054] First, refer to Figure 1 to Figure 8 , the container cap 1 of the present invention mainly includes: an outer cap 10, which is threadedly combined with the neck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com