Rack storage system

A technology of racking and warehouse, applied in the field of racking and warehouse system, can solve the problem of high cost of dimension setting, and achieve the effect of shortening assembly time, avoiding assembly errors and simple placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] As an introduction, it should first be stated that in the different described embodiments, the same reference numerals or the same component designations are provided for the same components, wherein the disclosure content contained in the entire description can be transferred to the On the same parts with the same reference numerals or the same component names. Furthermore, orientation specifications selected in the description, such as top, bottom, side, etc., relate to the direct description and the illustrated figure and can be transferred to the new orientation in the event of a change of orientation.

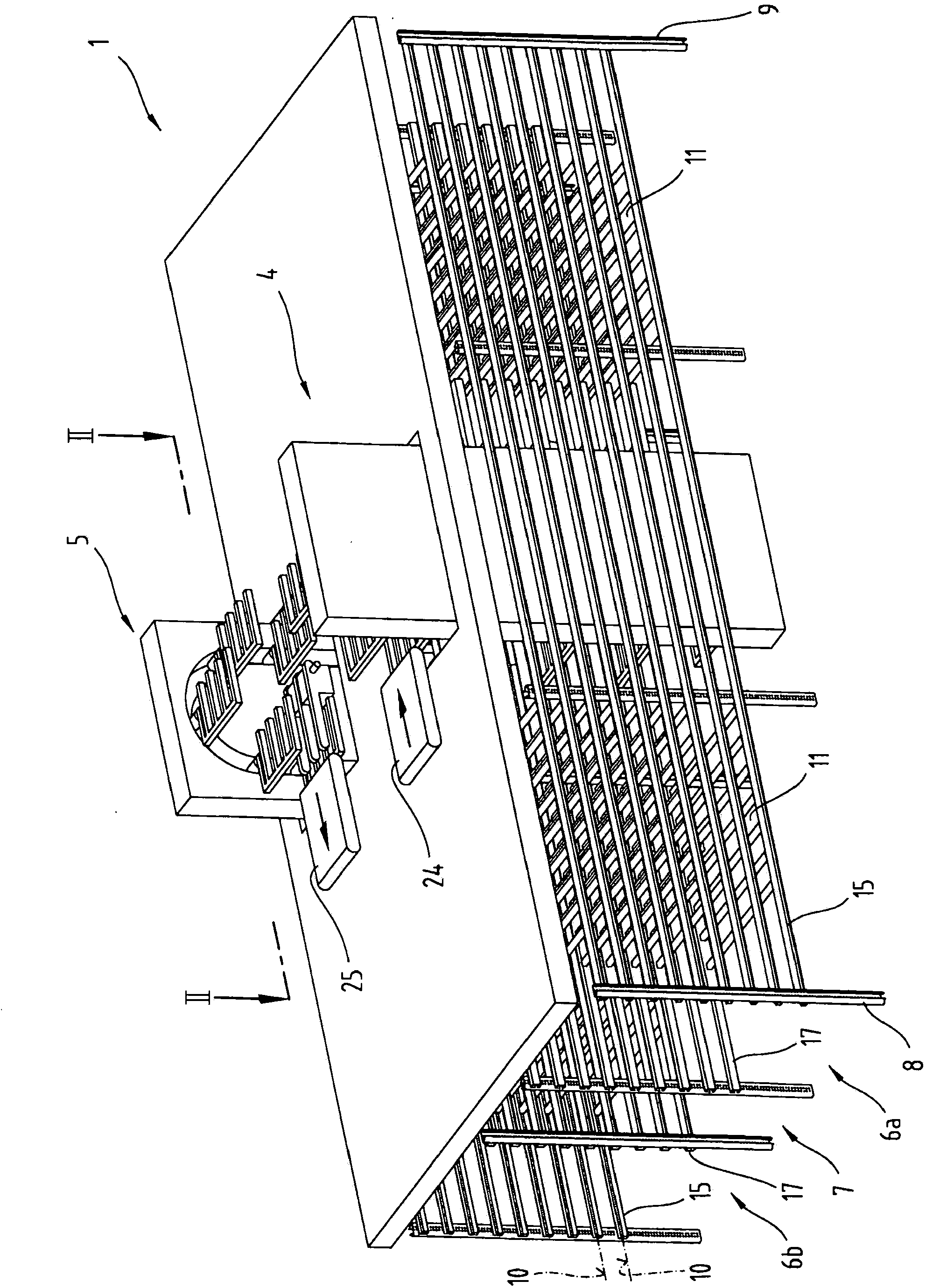

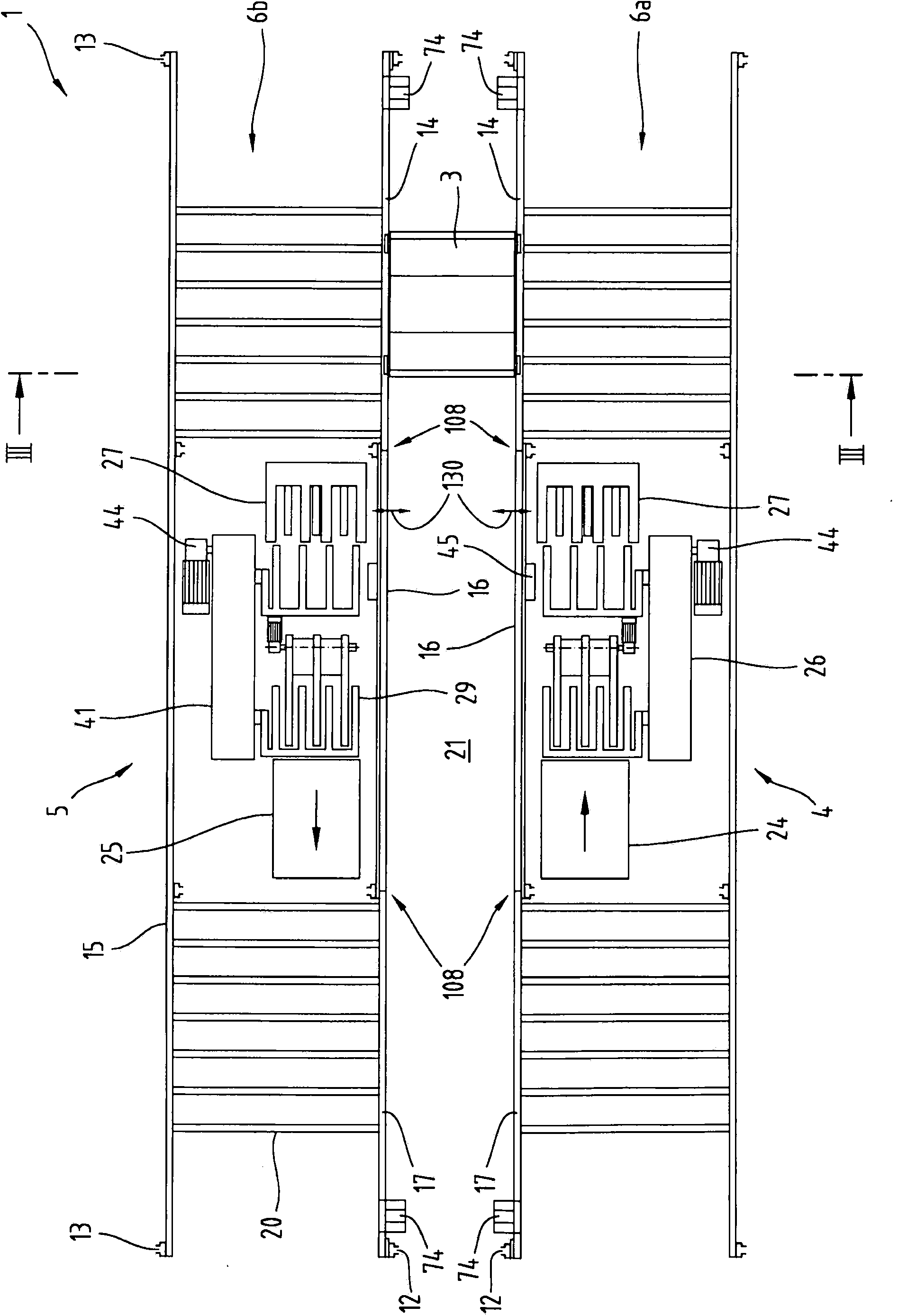

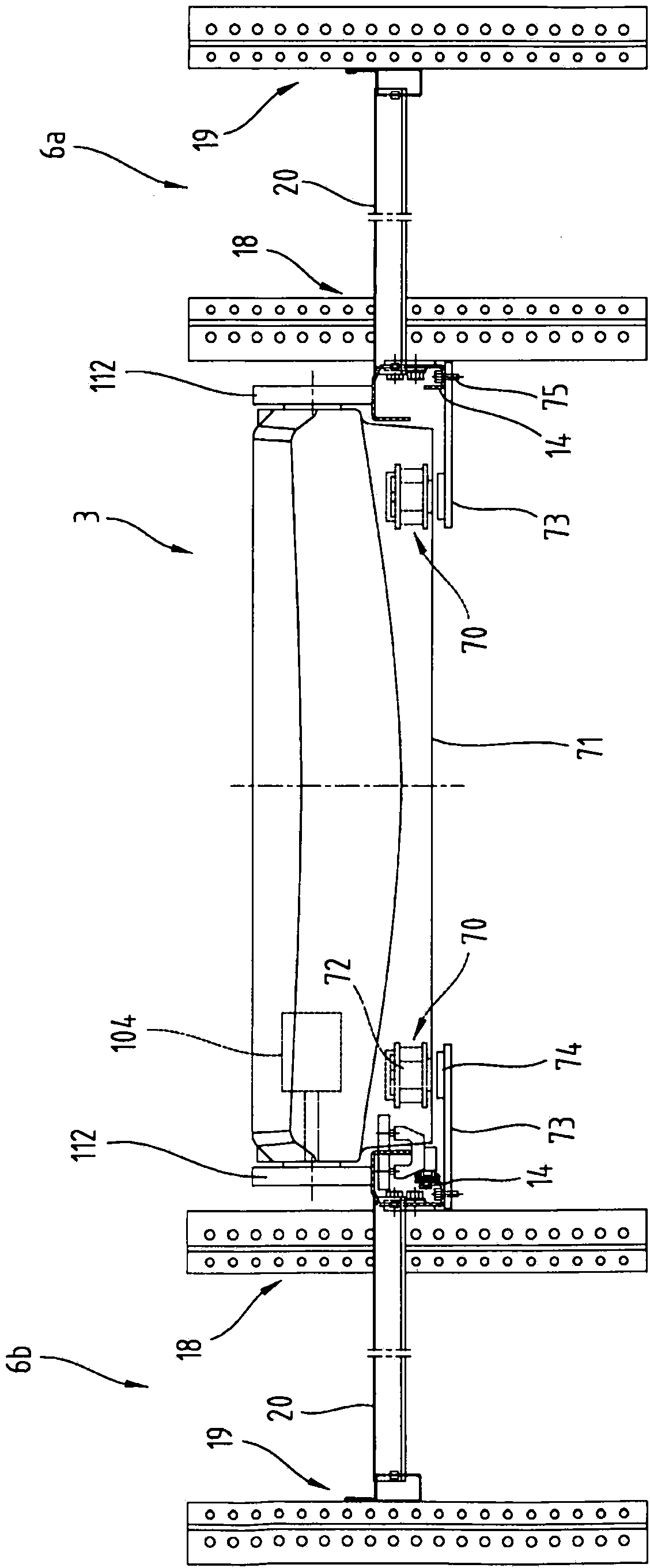

[0060] Figures 1 to 3 Shown is a rack storage system 1 comprising: a rack warehouse for loads 2, a self-propelled, independent at least one transport vehicle 3, a load lifting device 4 and, if necessary, a transport vehicle lifting device 5 .

[0061] Shown in the accompanying drawings is a possible implementation form of the rack warehouse system 1, which includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com