Device for fixing a lightweight panel on a support

A technology of fixing device and plate body, applied in the direction of thin plate connection, aircraft floor, transportation and packaging, etc., can solve problems such as damage to the mechanical properties of the plate body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

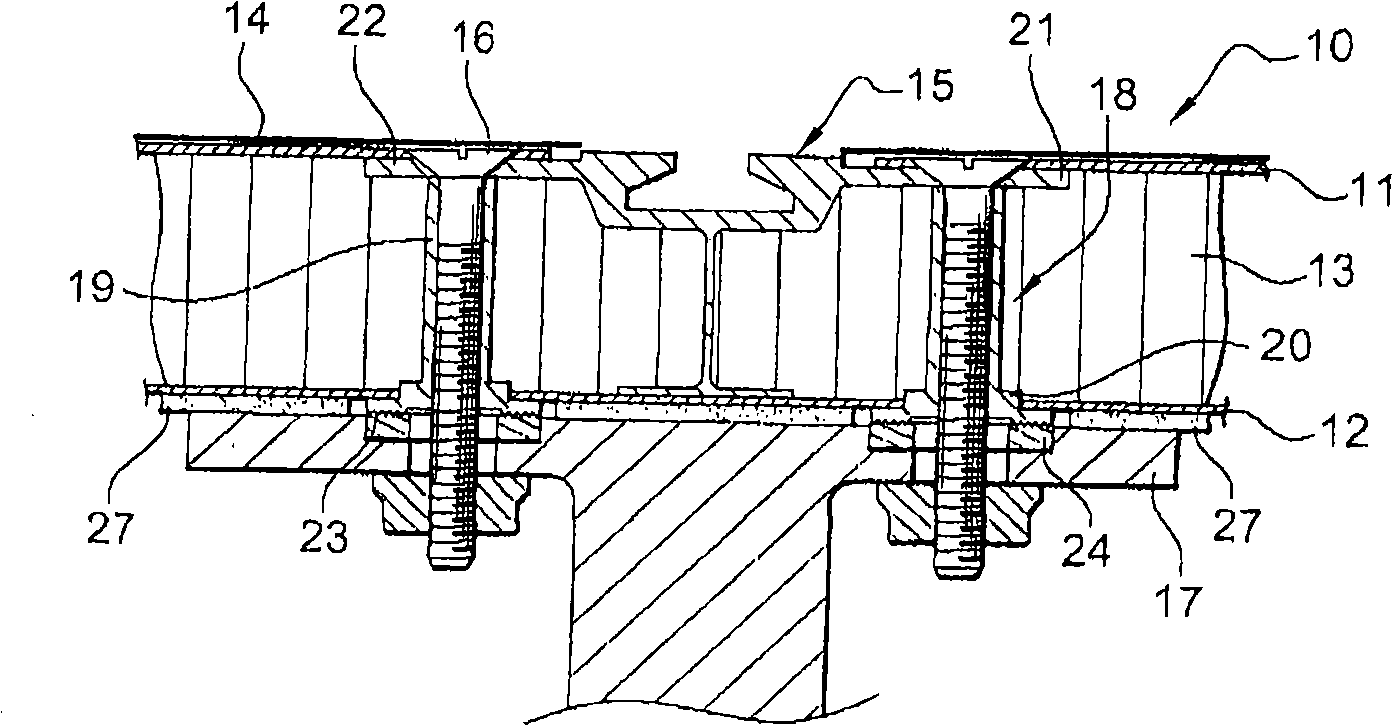

[0023] [twenty three] figure 2 Shown is a floor panel body for a passenger transportation vehicle according to an embodiment of the present invention. The floor panel 10 comprises a central sandwich structure comprising at least two walls 11 , 12 respectively located on opposite outer surfaces of a honeycomb core 13 .

[0024] [24] These walls 11, 12 are some fibrous skeletons. Fibers can be selected in the group given by way of non-limitation: carbon fibers, graphite fibers, glass fibers, silica fibers, silicon carbide fibers, or have the required Any other fiber that is defined in relation to light weight.

[0025] [25] The honeycomb core 13 is formed of, for example, aramide. Aramid fibers actually have low flammability, great fracture resistance and high modulus of elasticity.

[0026] [26] A floor covering 14 such as a carpet is positioned on the floor panel body 10 . The covering 14 serves to protect the floor panel 10 against movement-related erosion or other erosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com