Tension-chain sliding block and tension-chain head using same

A slider and zipper technology, applied in the application, sliding fastener components, fasteners and other directions, can solve the problems of many parts, complex structure, unfavorable zipper slider assembly operation, etc., to achieve simple operation, easy assembly, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

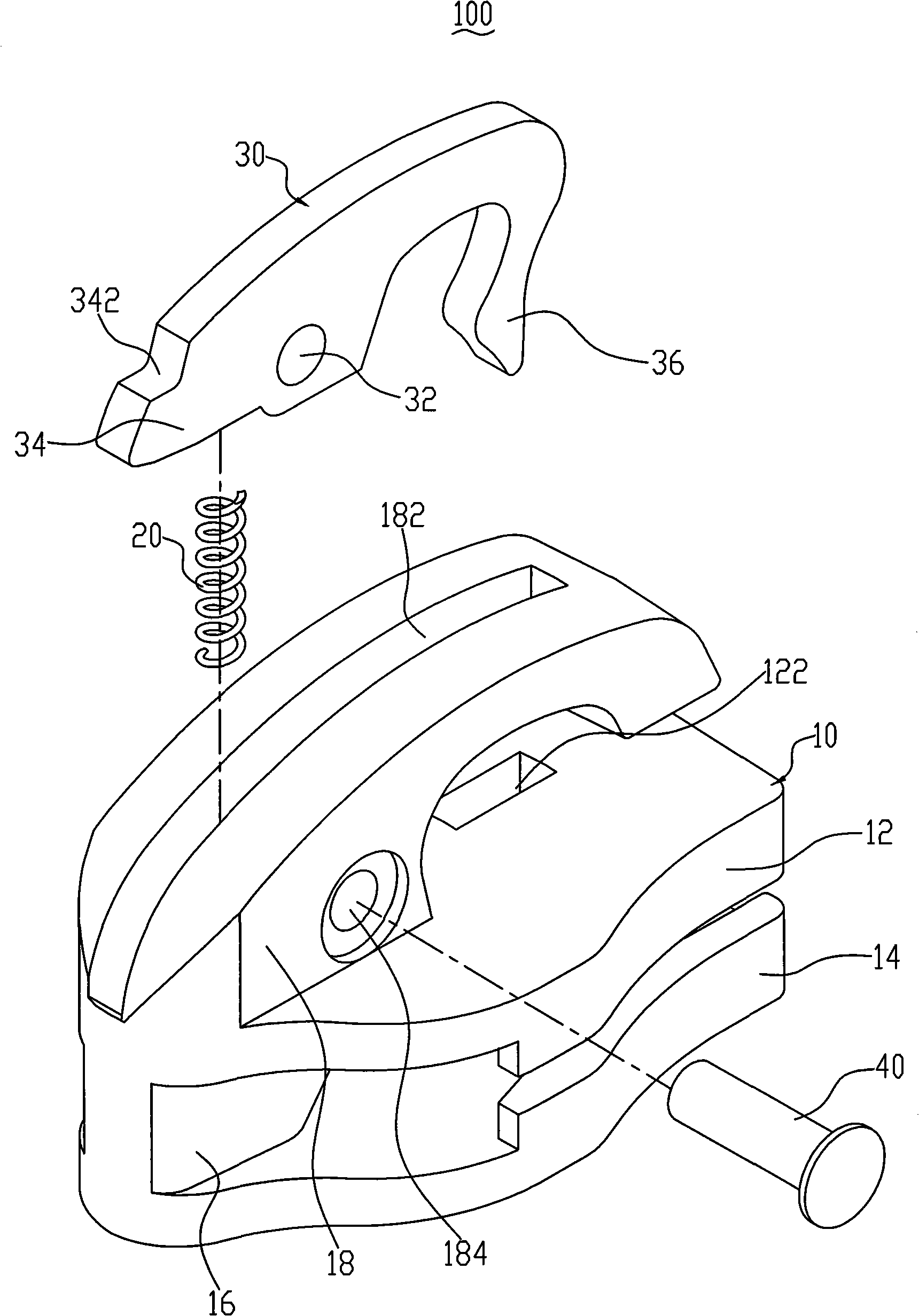

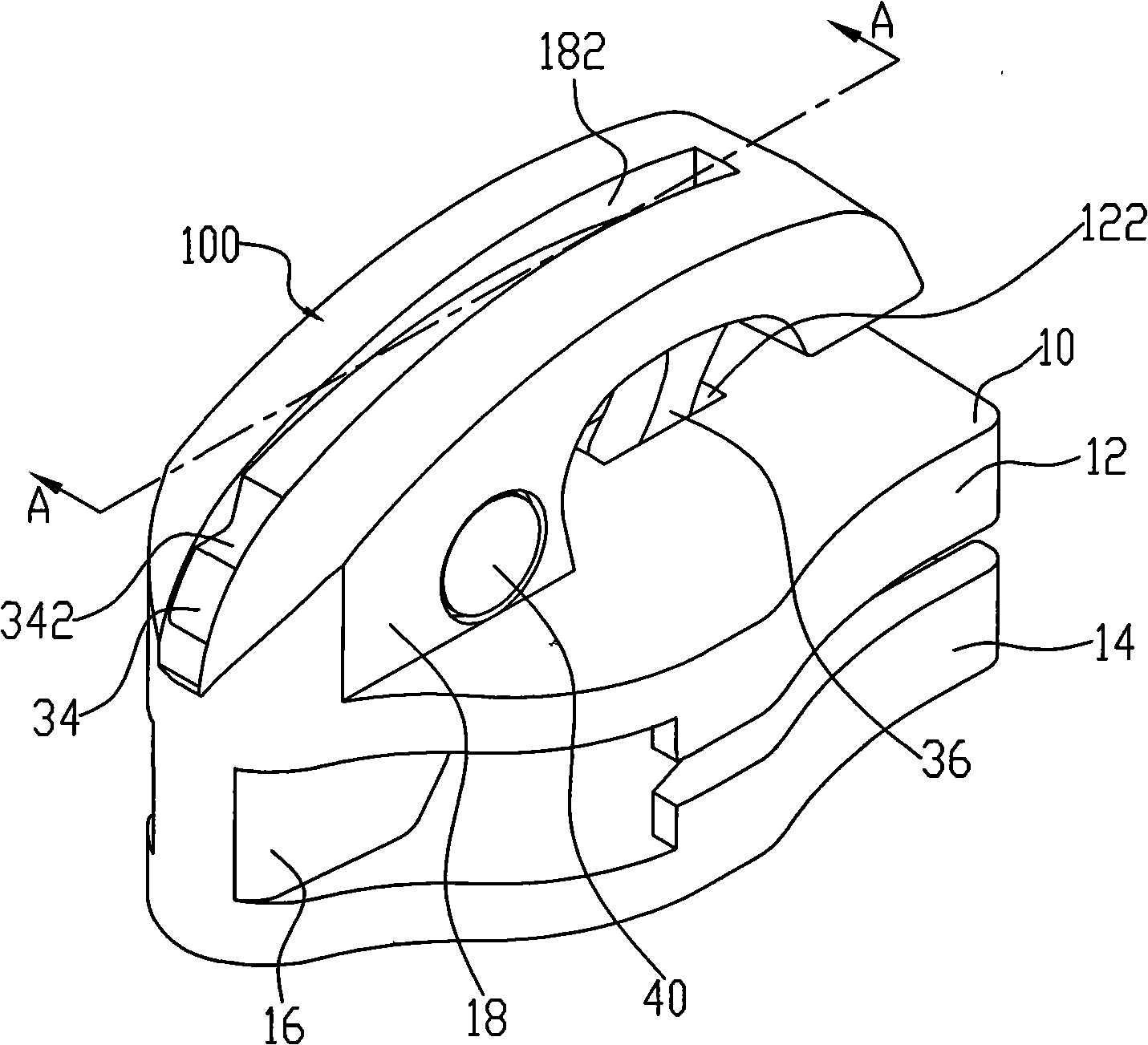

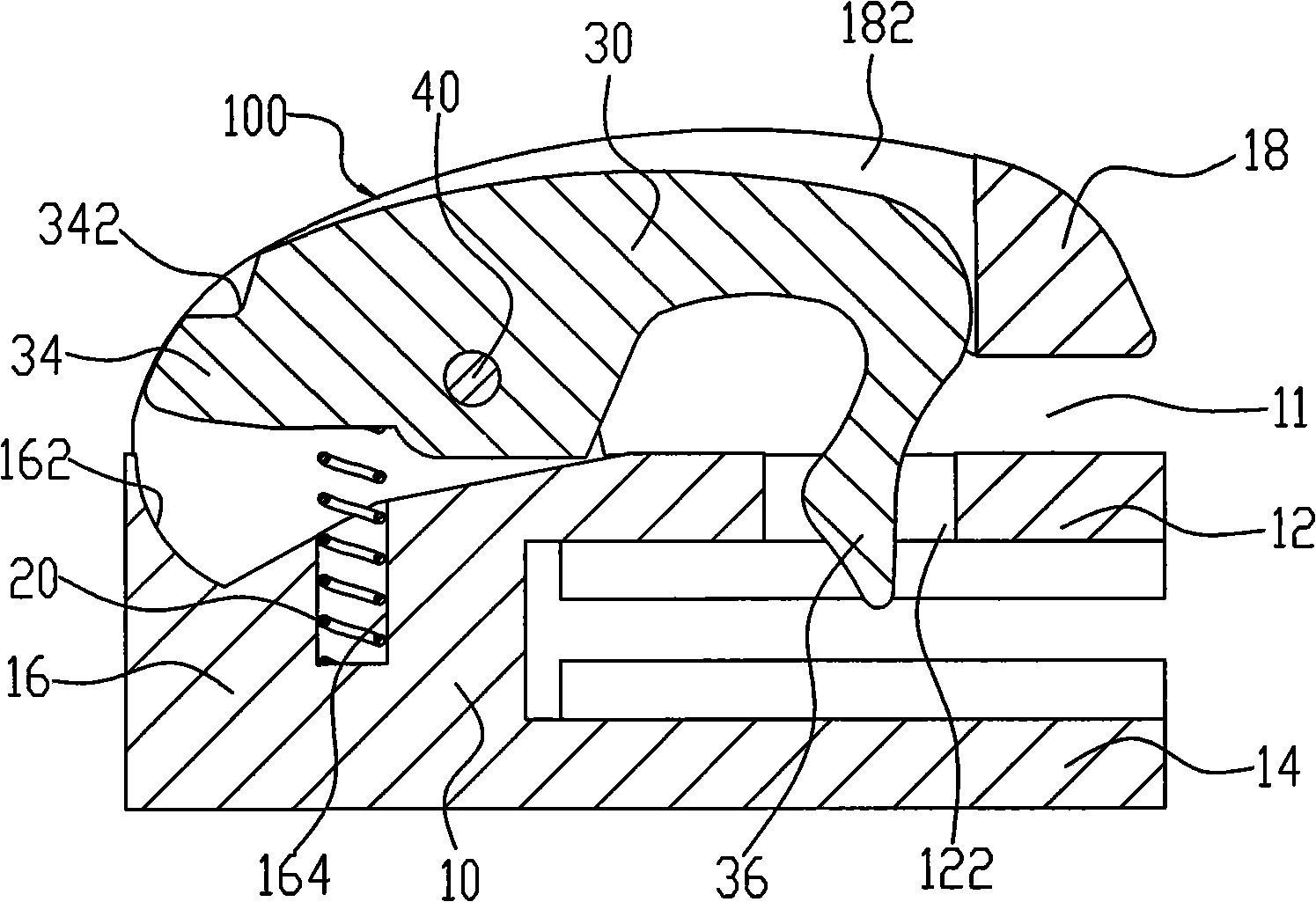

[0018] figure 1 Shown is a three-dimensional exploded view of the first embodiment of the slide fastener slider of the present invention. The zipper slider 100 includes a slider body 10 , an elastic element 20 , a self-locking element 30 and a rotating shaft 40 . The elastic element 20 and the self-locking element 30 are sequentially assembled on the slider body 10 (such as figure 2 and 3 shown).

[0019] Please refer to figure 1 and image 3 , the slider body 10 includes an upper wing 12 and a lower wing 14, the upper wing 12 and the lower wing 14 are connected by a guide column 16, thereby forming a substantially Y-shaped slideway for a The sprocket (not shown) of the zipper passes through. The upper wing plate 12 is provided with a pull-tab stopper 18 and a through hole 122, the pull-tab stopper 18 has an arc-shaped elongated structure as a whole, and the through hole 122 is located behind the upper wing plate 12 relative to the guide post 16. end. One end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com