Lithium battery cathode assembling machine

An assembly machine and lithium battery technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of harsh assembly environment, difficult to ensure plastic quality, and low assembly efficiency, so as to improve the working environment, good assembly quality, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific examples, but the specific examples do not limit the present invention in any way.

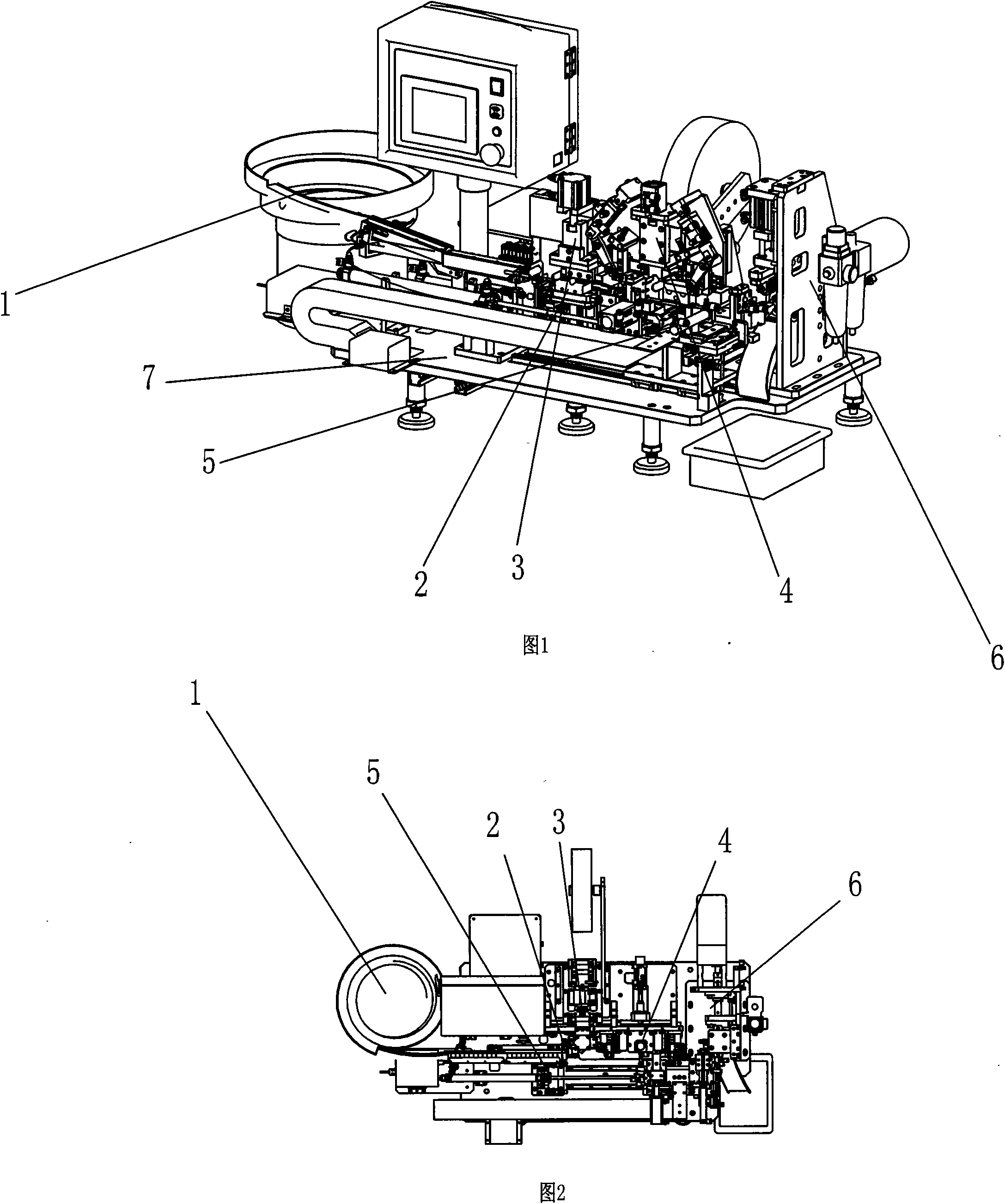

[0042] Such as Figure 1-8 As shown, the lithium battery negative electrode assembly machine of the present invention includes a workbench 7, on which a steel shell feeding device 1, a lithium sheet feeding and cutting device 2, a lithium sheet transferring device 3, a negative electrode shaping device 4, and a steel shell The transfer device 5 and the negative electrode rolling device 6 are all connected to the main control circuit.

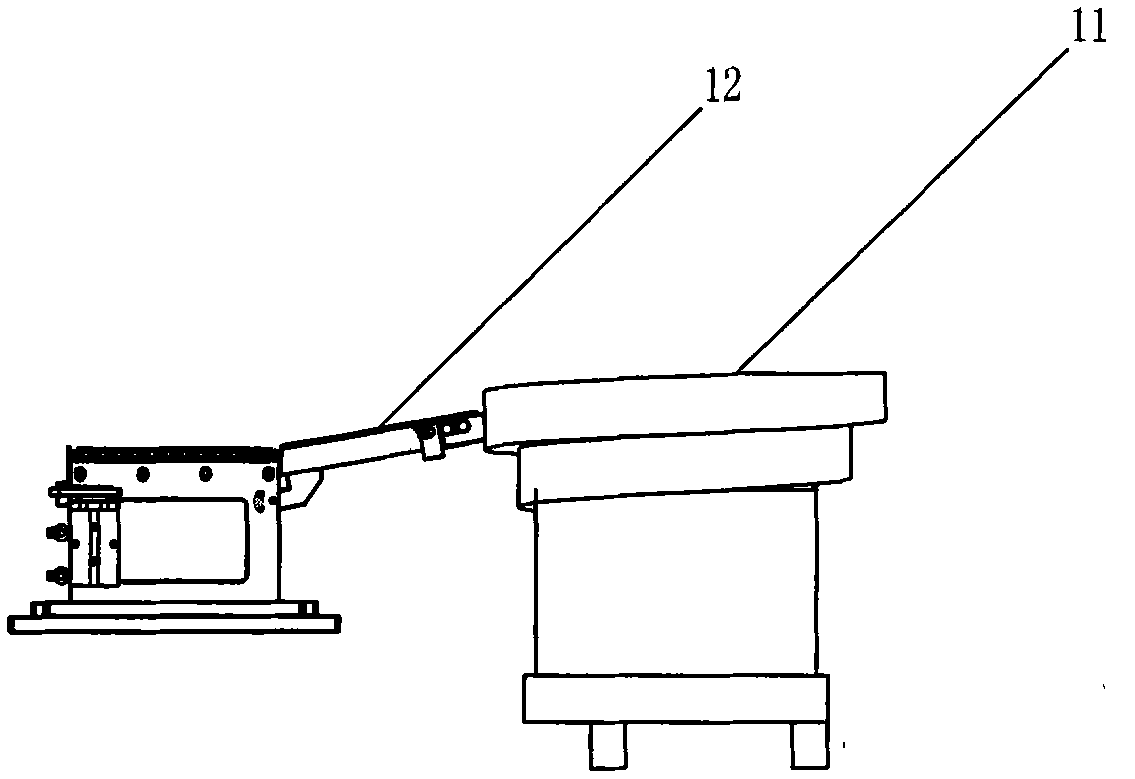

[0043] The above-mentioned steel shell feeding device 1 is composed of a vibrating plate 11 connected to a steel shell feeding channel 12 .

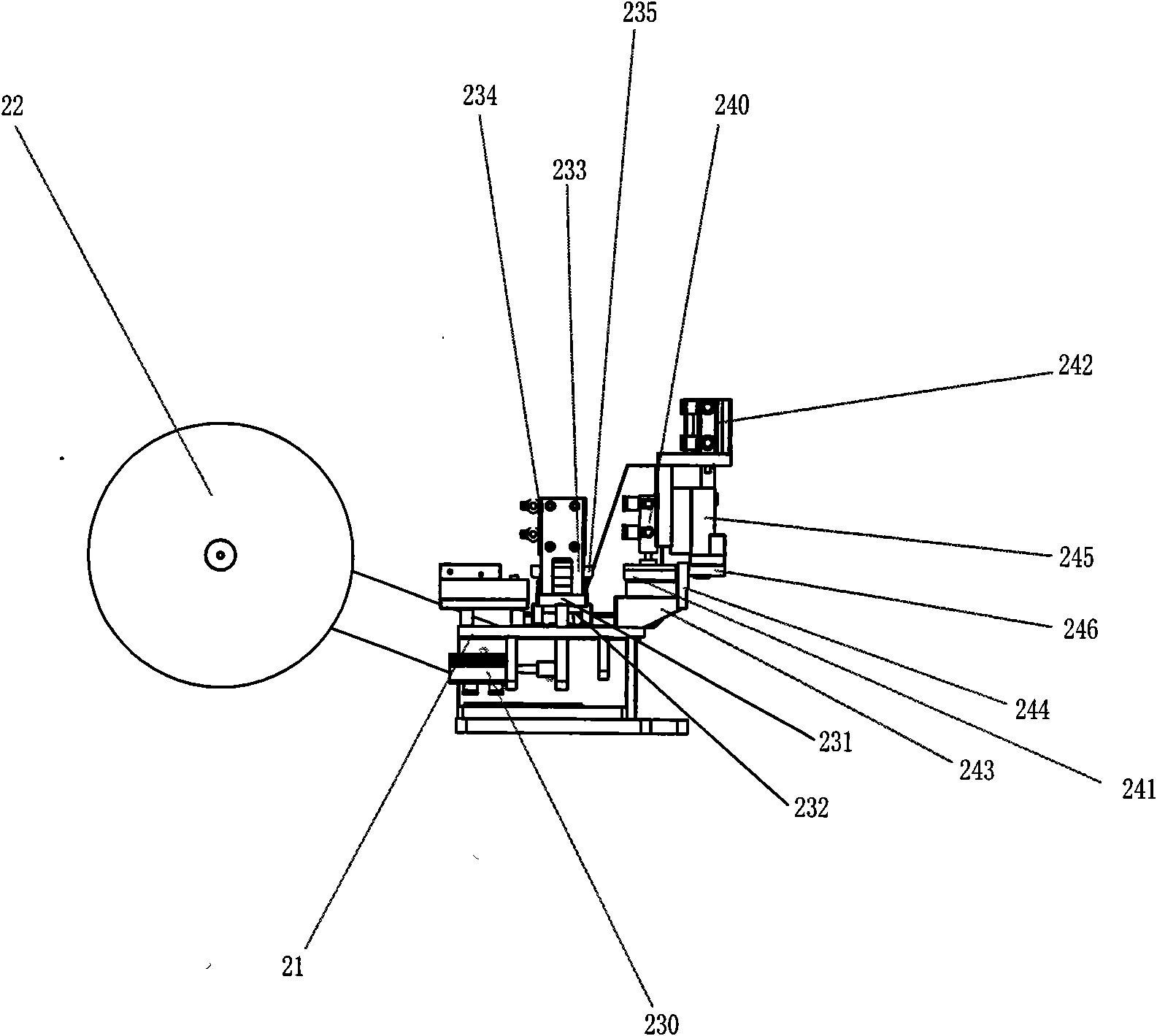

[0044] The above-mentioned lithium sheet cutting and sending device 2 includes a support 21, a lithium sheet feeding tray 22 is installed on one side of the support, and a lithium sheet feeding structure and a lithium sheet cutting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com