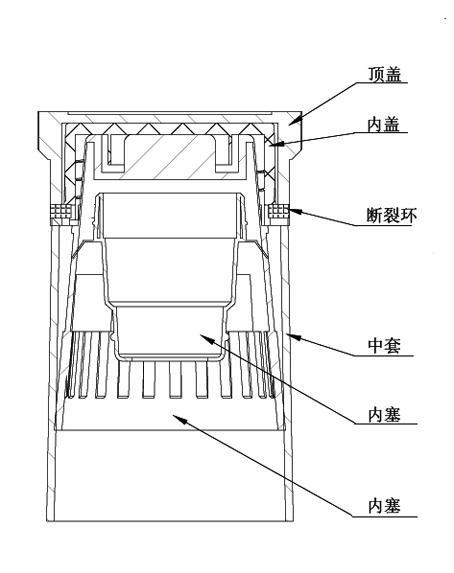

Numerical control bottle cap production line

A production line and bottle cap technology, applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency, complicated equipment, and complicated manufacturing methods, and achieve high production efficiency, high product quality, and small footprint small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described with reference to the accompanying drawings and examples.

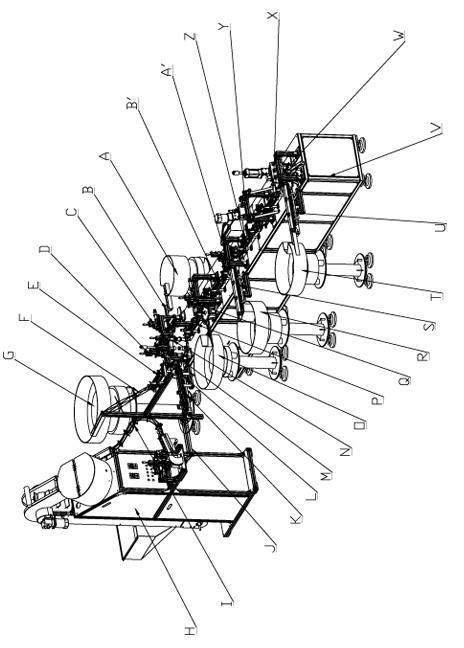

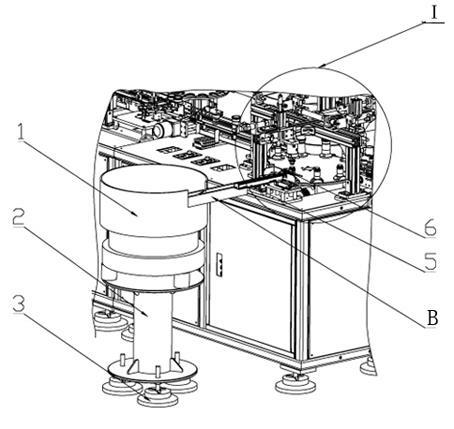

[0016] Production line of the present invention such as image 3 Shown is a complete production line.

[0017]The working process of each assembly process of the production line of the present invention is: put the inner plug into the inner plug feeding unit A, after sorting and sorting the inner plug feeding unit A, transport it to the inner plug assembly unit C through the vibrating plate slideway B, and put it into the inner plug assembly unit C. The inner plug on the tooling enters the next bottle nozzle assembly unit D process, and at the same time, the bottle nozzles equipped with bottle nozzle feeding unit G sorted and sorted are transported to the bottle nozzle assembly through the bottle nozzle slideway F and the bottle conveyor belt E Unit D, after the assembly is completed, enters the assembly unit L in the next process. At this time, the sorted produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com