Feeding manipulator used for hot forging production line

A production line and manipulator technology, applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems of large number of machines, high cost of use, low production efficiency, etc., and achieve high efficiency , The effect of reliable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

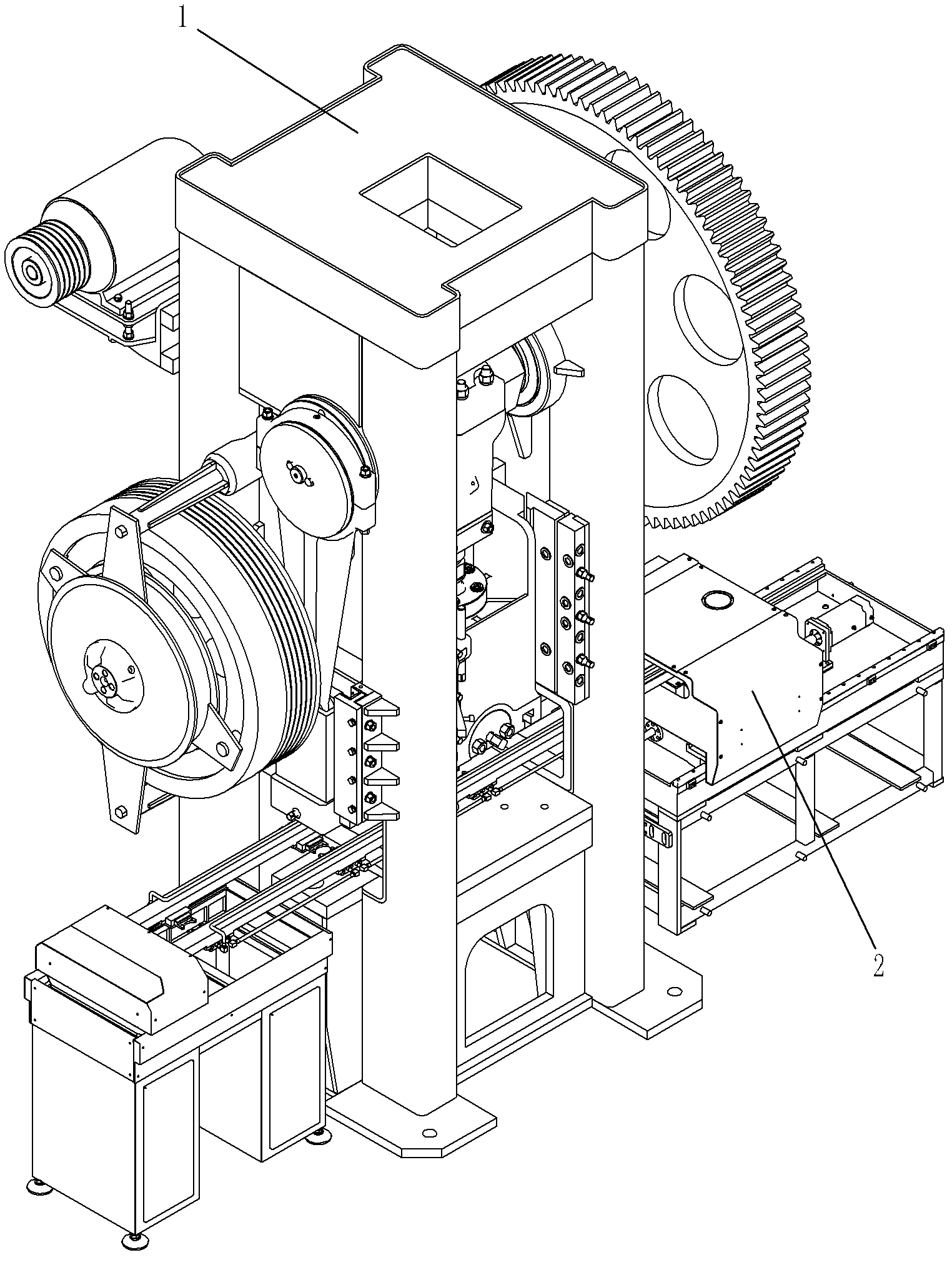

[0021] Such as figure 1 A hot forging production line shown includes a press 1 and a feeding manipulator 2 matched therewith.

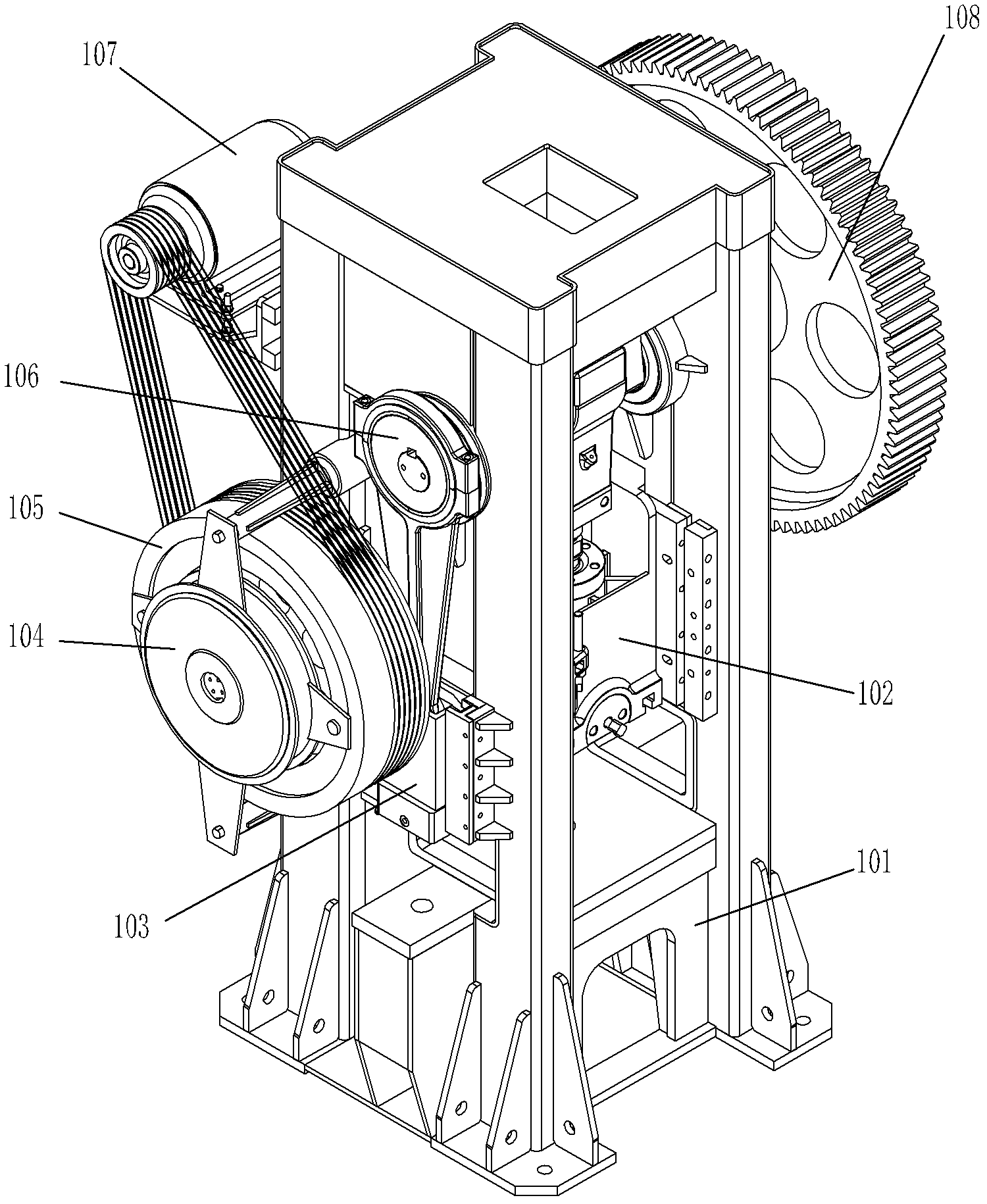

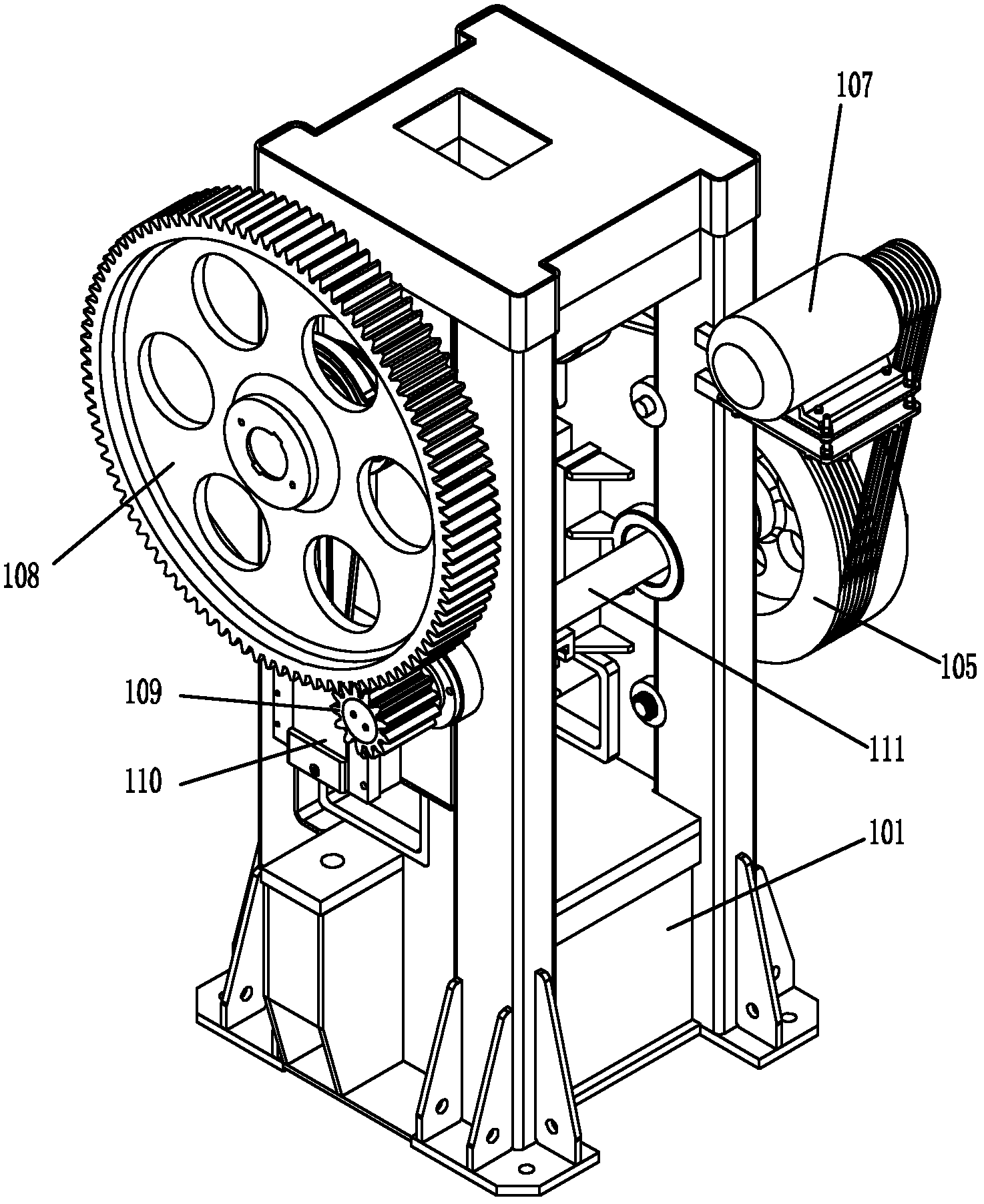

[0022] Such as figure 2 , image 3 , Figure 4 The shown press 1 for implementing hot forging includes a frame 101 on which a motor 107, a flywheel 105, a clutch brake 104, a transmission shaft 111, a crankshaft 112, a slider A102, a slider B103, a slider Block C110, wherein the transmission shaft 111 and the crankshaft 112 are respectively rotated and arranged on the wall panels on both sides of the frame 1, a flywheel 105 and a clutch brake 104 are installed at one end of the transmission shaft 111, and the flywheel 105 is connected to the motor 107 in transmission, and the other end of the transmission shaft 111 The pinion gear 109 is connected to the large gear 108 installed at one end of the crankshaft 112. The slider A102 is vertically slidably arranged between the wall panels on both sides of the frame 101 and is driven by the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com