Automatic plate packing machine

An automatic film-packing machine and film-packing technology, which is applied to electrode manufacturing and other directions, can solve the problems of complex structure, single production method, and impact on the health of operators, and achieve high work efficiency, compact structure, and improved work efficiency and work range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

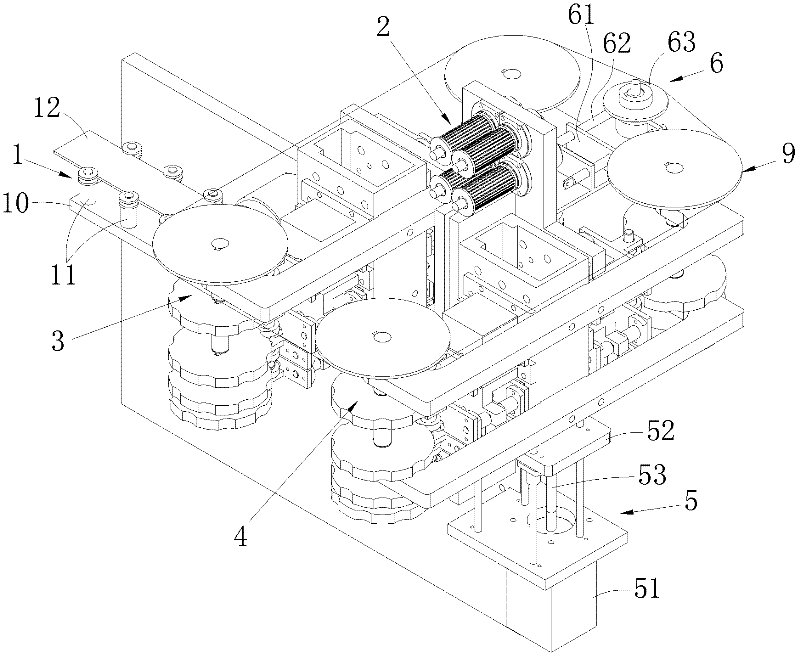

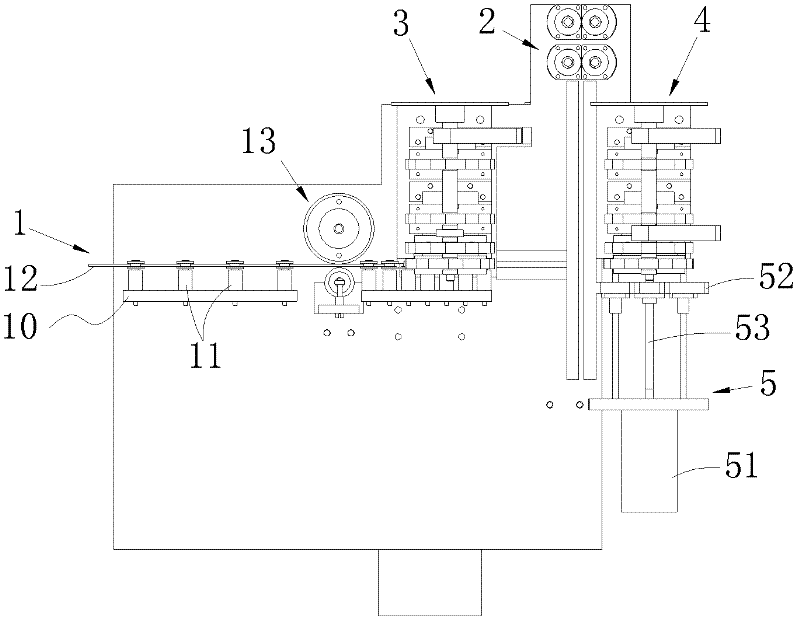

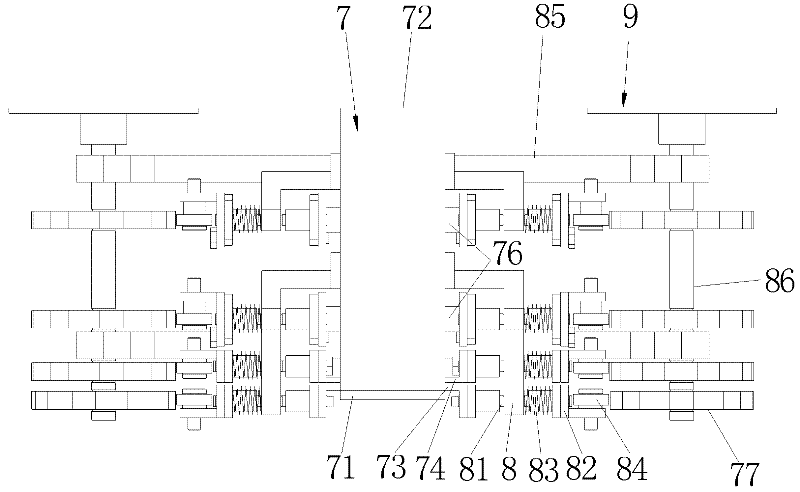

[0022] refer to figure 1 , 2 , an automatic wrapping machine, including a pushing mechanism 1 for pushing pole pieces, a paper feeding mechanism 2 for conveying separator paper, a first piece feeding mechanism 3 for conveying the first pole piece, a second conveying mechanism for conveying the second pole piece Sheet mechanism 4, assembling mechanism 5, its described first sheet feeding mechanism 3, paper feeding mechanism 2, second sheet feeding mechanism 4 are arranged in sequence along the advancing direction of sheet pushing mechanism 1, and described assembling mechanism 5 is arranged on the second Right below the second sheet feeding mechanism 4; the first pole piece is transported to the sheet pushing mechanism 1 by the first sheet feeding mechanism 3, and the paper feeding mechanism 2 cooperates with the sheet pushing mechanism 1 to complete the wrapping of the first electrode piece; The sheet is transported to the assembly mechanism 5 by the second sheet feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com