Bending machine used for bending plates

A bending machine and bending technology, used in metal processing equipment, feeding devices, positioning devices, etc., can solve problems such as reducing accuracy and work efficiency, and achieve the effect of improving efficiency, ensuring accuracy, and achieving obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

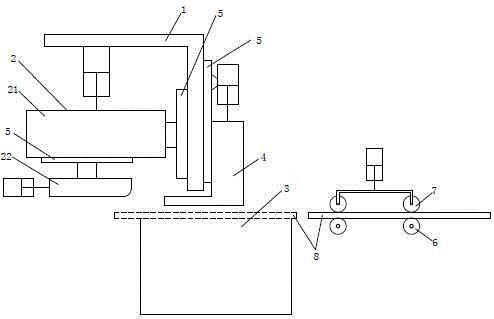

[0012] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0013] figure 1 It shows the bending machine used for plate bending provided by the present invention, including the frame 1, the upper bending part 2, the lower bending part 3 and the feeding mechanism, the lower bending part 3 is fixedly arranged, and the upper bending part 2 Set by sliding up and down; the upper part of the lower bending part 3 is correspondingly provided with a pressure plate 4, and the pressure plate 4 is set by sliding up and down; The moving platen 22 is located on the lower surface of the top block 21, and is reciprocally slid along the feeding direction. The sliding platen 22 is equipped with a sliding drive device; corners to make the pressing down more smoothly and avoid sharp corners from causing damage to the material. There is a bending gap between the sliding platen 22 and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com