Automatic assembling device for fuel gas meters

A technology for assembling devices and gas meters, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in ensuring product quality stability, high work intensity of operators, and low consistency, so as to reduce labor costs and reduce labor costs. Management cost, stable product quality, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

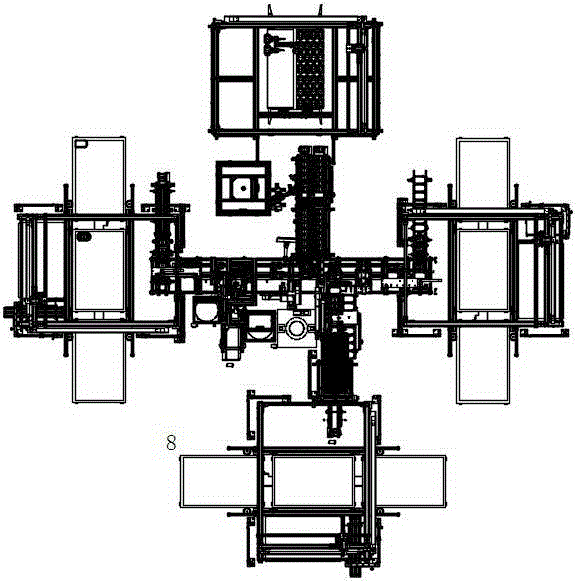

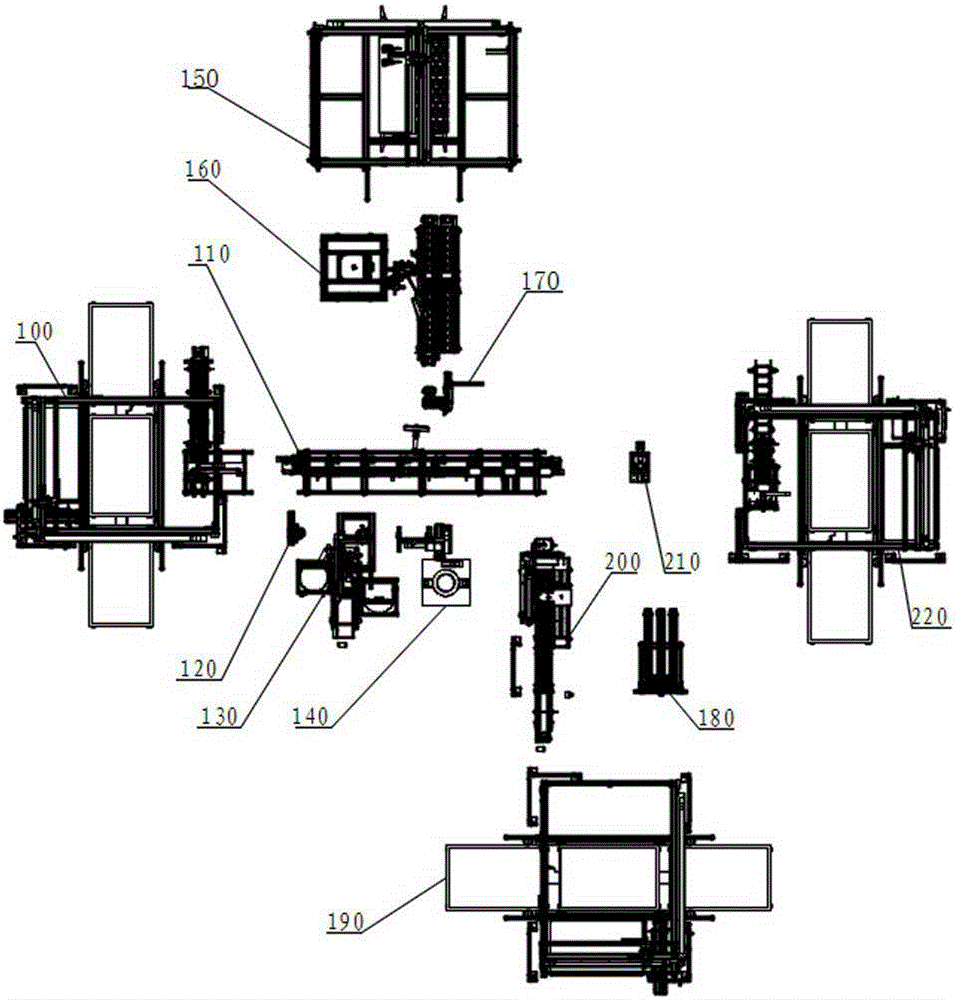

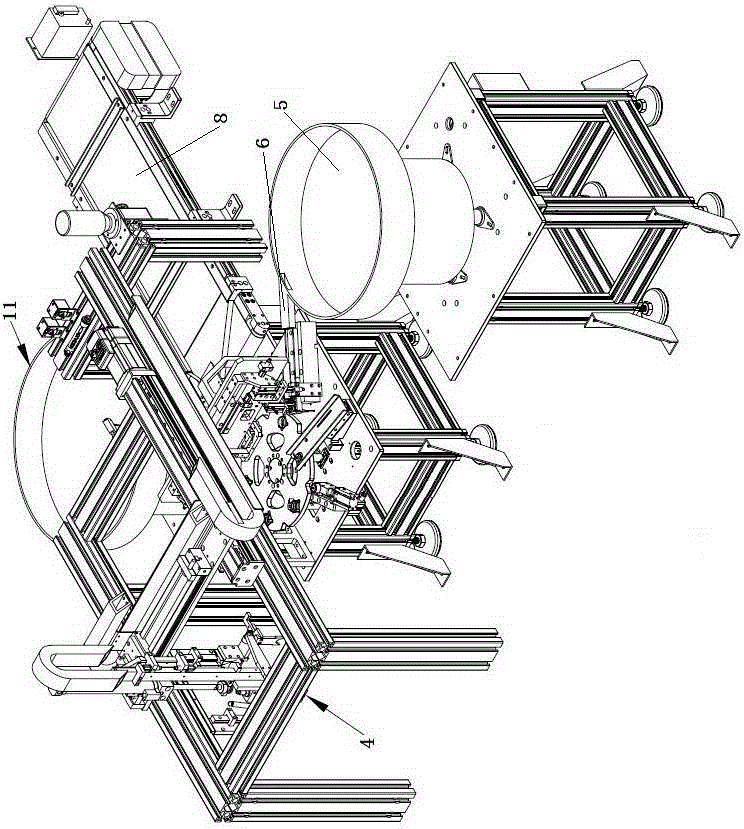

[0052] As shown in the figure, the gas meter automatic assembly device includes an upper cover feeding module 100, a circular guide rail conveying module 110, an upper cover shaft oiling module 120, a magnetic steel group assembly module 130, a glue applying module 140, and a movement feeding module 150 , air outlet pipe assembly module 160 , movement assembly module 170 , sealing ring feeding module 180 , lower cover loading module 190 , lower cover assembly module 200 , sealing ring pre-pressing module 210 , and table-forming unloading module 220 .

[0053] When using the present invention to assemble the gas meter, the upper cover feeding module 100 first takes out the upper cover of the gas meter from the material box, and puts it into the tooling of the annular guide rail conveying module 110; the annular guide rail conveying module 110 moves the upper cover to the upper The cover shaft oiling station, the upper cover shaft oiling module 120 oils the upper cover shaft; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com