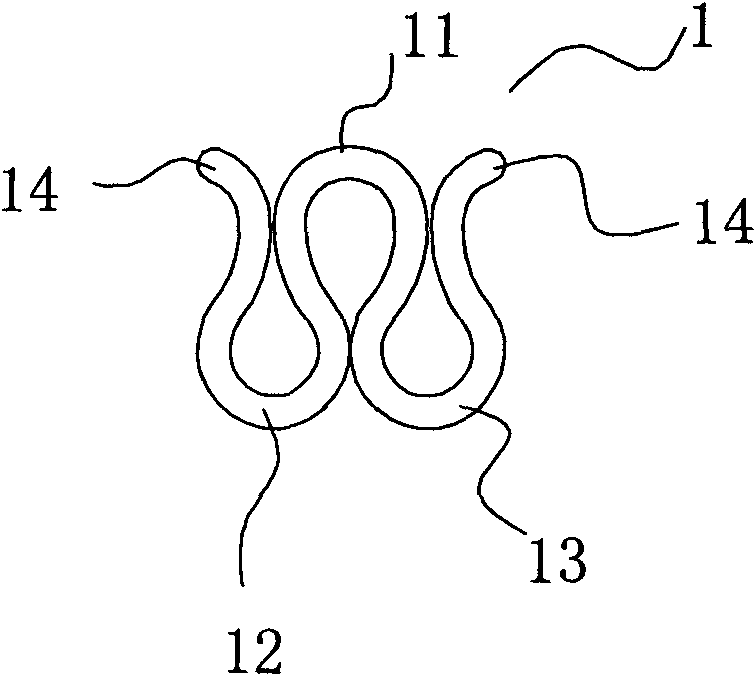

Automatic shaping device and automatic shaping method of W-shaped necklace buckle

An automatic forming and necklace technology, applied in watch chains, decorative chains, other household appliances, etc., can solve the problem of high labor intensity, and achieve the effects of increased output, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

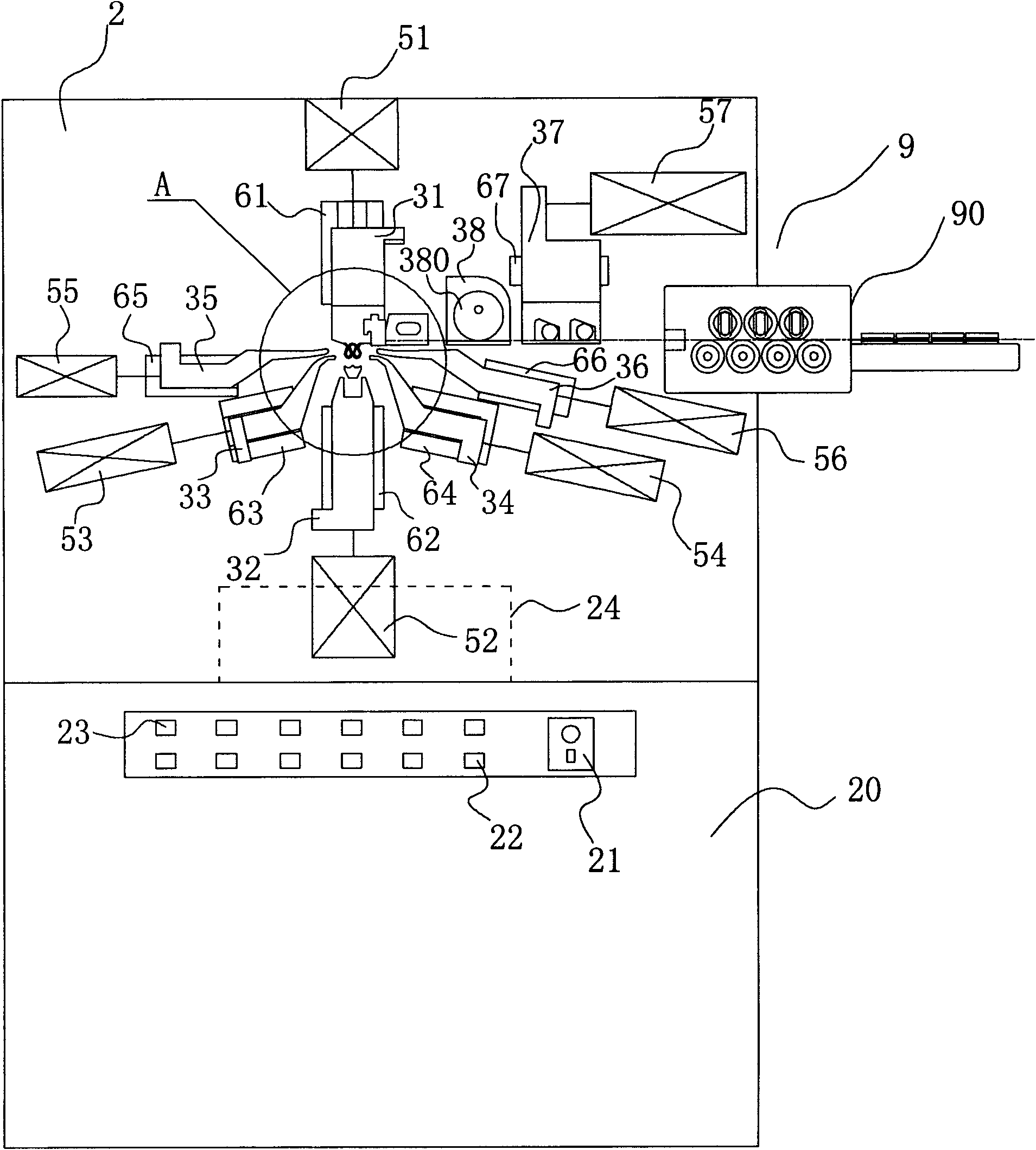

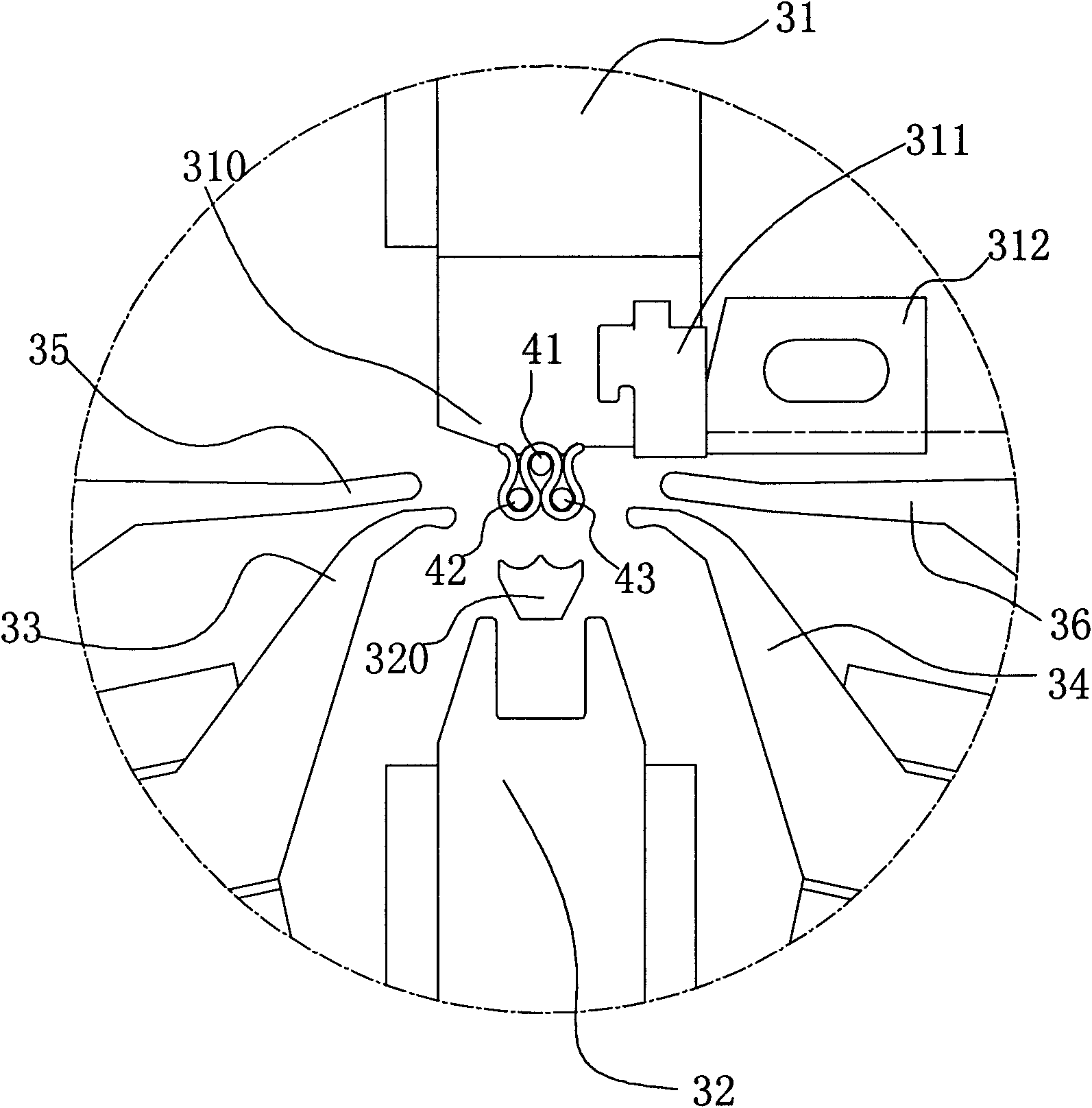

[0060] Such as Figure 1 to Figure 4 As shown, the W-type necklace buckle automatic forming device of the present invention includes a template 2, a feeding mechanism 9 located on one side of the template 2, a first core 41 located on the template 2, and a cutting section located above the first core 41. The bending die 31, the extrusion die 32 located directly below the first core 41, and the second core 42 and the third core located on the left and right sides between the first core 41 and the extrusion die 32 43; the template 2 is also provided with a left outer mold 33 and a right outer mold 34 on the left and right sides of the first core 41, and a second outer mold 35 and a third outer mold 36. The feeding mechanism 9 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com