Method for winding joint-free high-temperature superconducting four-cake coil

A technology of high-temperature superconductivity and winding method, which is applied in the direction of superconducting magnet/coil, inductor/transformer/magnet manufacturing, electrical components, etc., which can solve the problems of performance degradation, easy damage, and increase of superconducting joints, etc., and achieve operation Convenience, simple principle, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

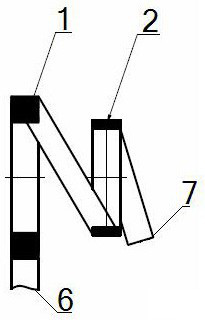

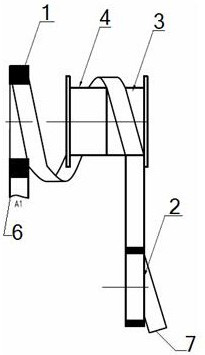

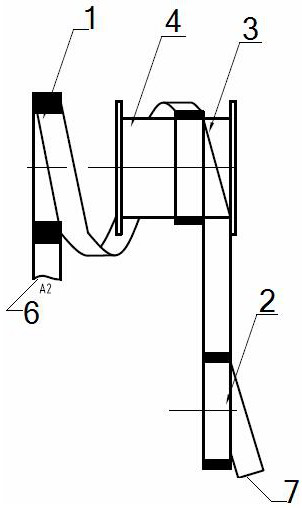

[0036] A method for winding a jointless high-temperature superconducting four-cake coil, comprising the following steps:

[0037] Step 1, the wound four-cake coils are named from right to left as No. 1 cake, No. 2 cake, No. 3 cake, and No. 4 cake; wind the 1 / 4 section of the strip at the head of the main coil 1 on another transition On the reel 2, wind the middle 2 / 4 section strip of the main reel 1 on the right skeleton 3 of the double cake coil to complete the winding of the second cake;

[0038] Step 2, winding the strip on the transition reel 2 to complete the winding of the No. 1 cake;

[0039] Step 3, wind the middle 3 / 4 strip of the main reel 1 on the left transition frame 4 of the double pie coil, and wind the remaining 4 / 4 strip of the main reel 1 on the left skeleton 5 of the double pie coil On, complete the winding of the fourth cake;

[0040] Step 4, rewind the 3 / 4 section of the strip wound on the left transition frame 4 on the left frame 5 of the double cake co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com